Preparation method of anti-infrared cool modified nylon filament adopting skin-core structure

A skin-core structure, infrared technology, used in rayon manufacturing, filament/thread forming, conjugated synthetic polymer rayon, etc., can solve the problem that the effect of anti-infrared function finishing is not long enough, the wearing is not cool enough, and the infrared ray is ignored. protection and other issues, to achieve the effect of good anti-infrared heat insulation performance and excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

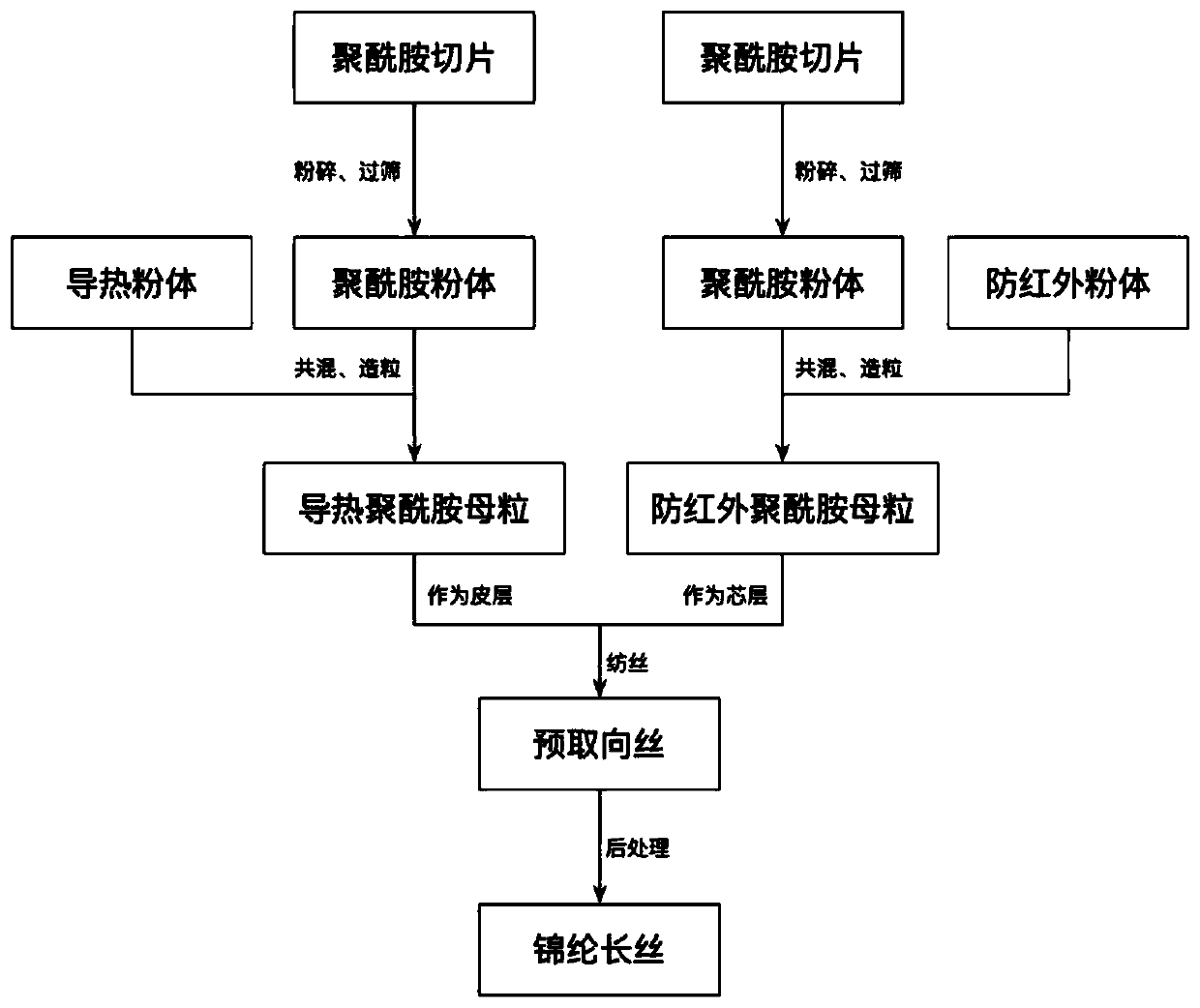

[0026] The invention provides a preparation method of anti-infrared cool modified nylon filament with a skin-core structure, which adopts concentric sheath-core spinning assembly for spinning, and its core layer contains infrared reflective powder, and the infrared reflective powder is made of nano-silica One or more blends of powder, nano-carbon powder, tungsten-vanadium-tin-antimony oxide powder account for 3% to 5% of the core layer; the skin layer contains heat-conducting powder, and the heat-conducting powder is made of nano-jade One or more kinds of powder, nano aluminum nitride and mica nano powder are blended, accounting for 2% to 3% of the cortex mass. The preparation method comprises the following steps:

[0027] step one

[0028] The high-viscosity polyamide chips are cryogenically treated, crushed and sieved to obtain polyamide powders with a mesh size of 150-300. Preferably, the high-viscosity polyamide chips are polyamide 6 chips, with a chip viscosity of 2.8-3...

Embodiment 1

[0049] Step (1): The high-viscosity polyamide 6 slices are cryogenically treated, crushed and sieved to obtain 150-mesh polyamide powder. Polyamide 6 has a slice viscosity of 3.0dL / g and a melting point of 225°C.

[0050] Step (2): Silica with a particle size of 50nm is mixed with the polyamide powder obtained in step (1) at a high speed in a mass ratio of 10:90, and then melted, blended, extruded and granulated by a twin-screw extruder, A modified anti-infrared polyamide masterbatch is prepared. The rotation speed of the mixer is 400 rpm, the mixing temperature is 90° C., and the mixing time is 0.5 h.

[0051] Step (3): subjecting polyamide slices with medium viscosity and low melting point to cryogenic treatment, crushing and sieving to obtain polyamide powder with a mesh size of 150. The polyamide chips are polyamide 6 chips with a chip viscosity of 2.4dL / g and a melting point of 215°C.

[0052] Step (4): Add aluminum nitride with a particle size of 5nm and mix the polya...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap