Whole-hydraulic spraying seeding machine slurry pump whole-hydraulic driving system

A drive system, full hydraulic technology, used in machines/engines, liquid variable capacity machinery, liquid fuel engines, etc., can solve problems such as large troubleshooting, easy access to air, pipeline adjustment, etc., to shorten the troubleshooting time. , less energy transfer mode, ensure the effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

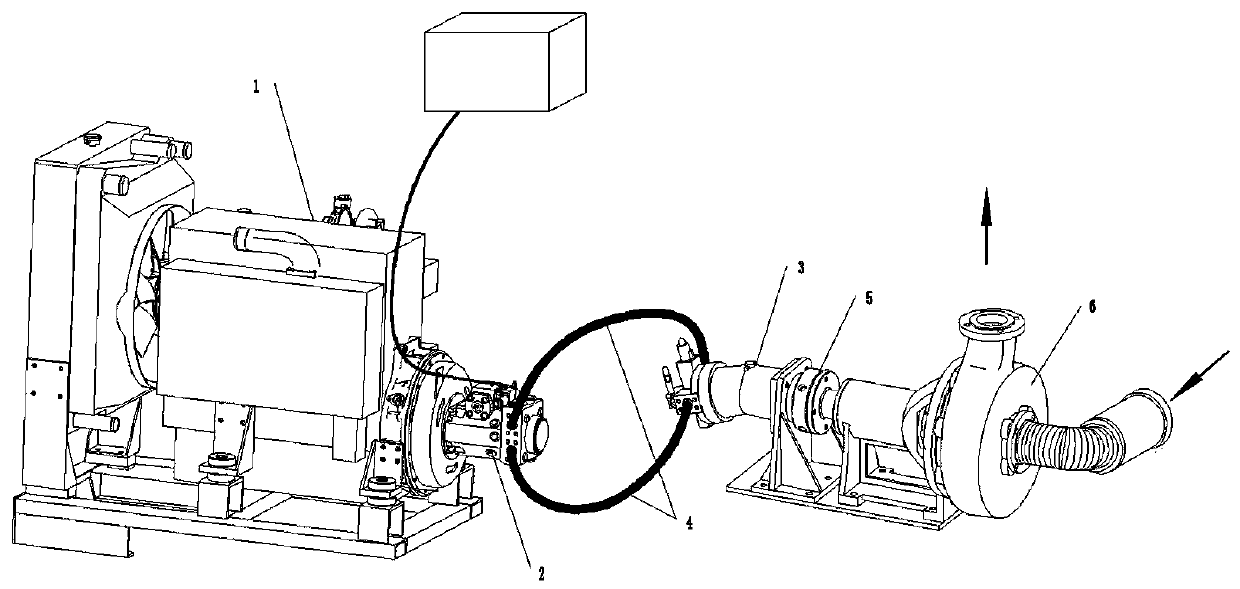

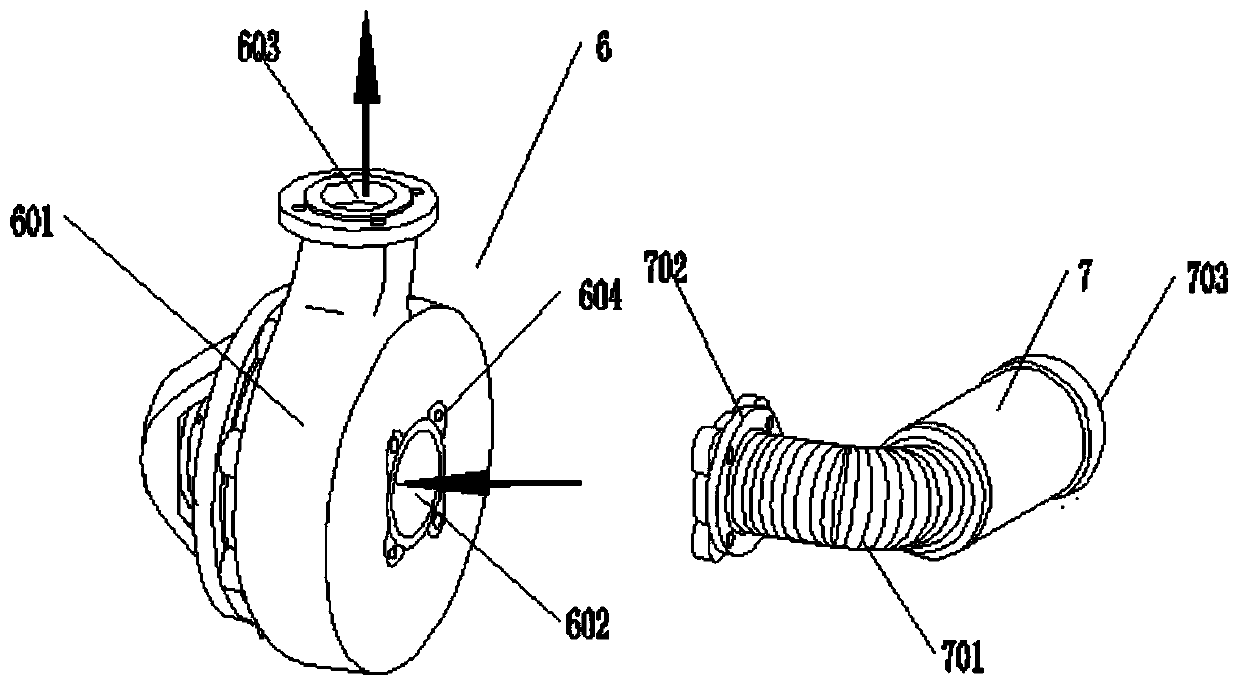

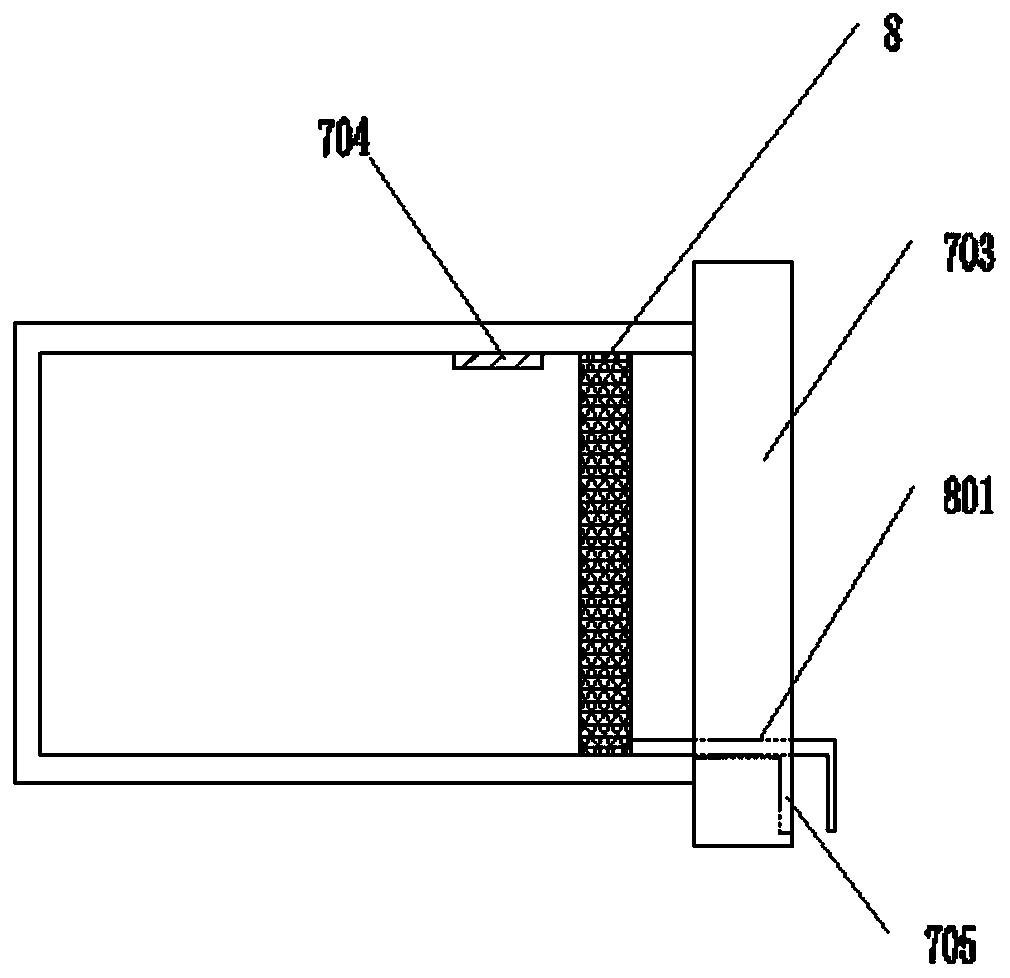

[0021] see Figure 1-4 As shown in the figure, a full hydraulic drive system for a mud pump of a fully hydraulic sprayer includes a diesel engine 1 that provides piston power, a variable closed pump 2 that converts piston power into hydraulic pressure, and a closed motor that converts hydraulic pressure into rotational force 3 and the centrifugal pump 6 used for mud pressurization. The variable closed pump 2 is installed on the diesel engine 1. The variable closed pump 2 is equipped with a connecting oil pipe 4. The closed pump 2 transmits the hydraulic pressure to the closed pump through the connected oil pipe 4. Motor 3, a coupling 5 is installed on one side of the closed motor 3, and the closed motor 3 transmits power to the centrifugal pump 6 through the coupling 5, and the centrifugal pump 6 includes a volute 601, an inlet 602 and an outlet 603 , a feed pipe 7 is installed on the feed port 602, and one end of the feed pipe 7 is connected with a folded hose 701, and the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com