Quick detection and evaluation method of harmful precipitated phase in two-phase stainless steel

A technology of duplex stainless steel and evaluation method, applied in testing metals, analyzing materials, measuring devices, etc., can solve the problems of inability to perform on-site analysis of the equipment itself, disadvantages, etc., and achieve the effect of saving cost, time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A rapid detection and evaluation method for harmful precipitated phases in duplex stainless steel. In the duplex stainless steel used in the scheme, the alloy elements include not more than 0.03% of C, not more than 2% of Mn, and 22 to 23% of Cr in the duplex stainless steel. , 4.5-6.5% Ni, 3.0-3.5% Mo, not more than 1% Si, 0.14-0.20% N, not more than 0.02% S, not more than 0.03% P, and the balance is Fe.

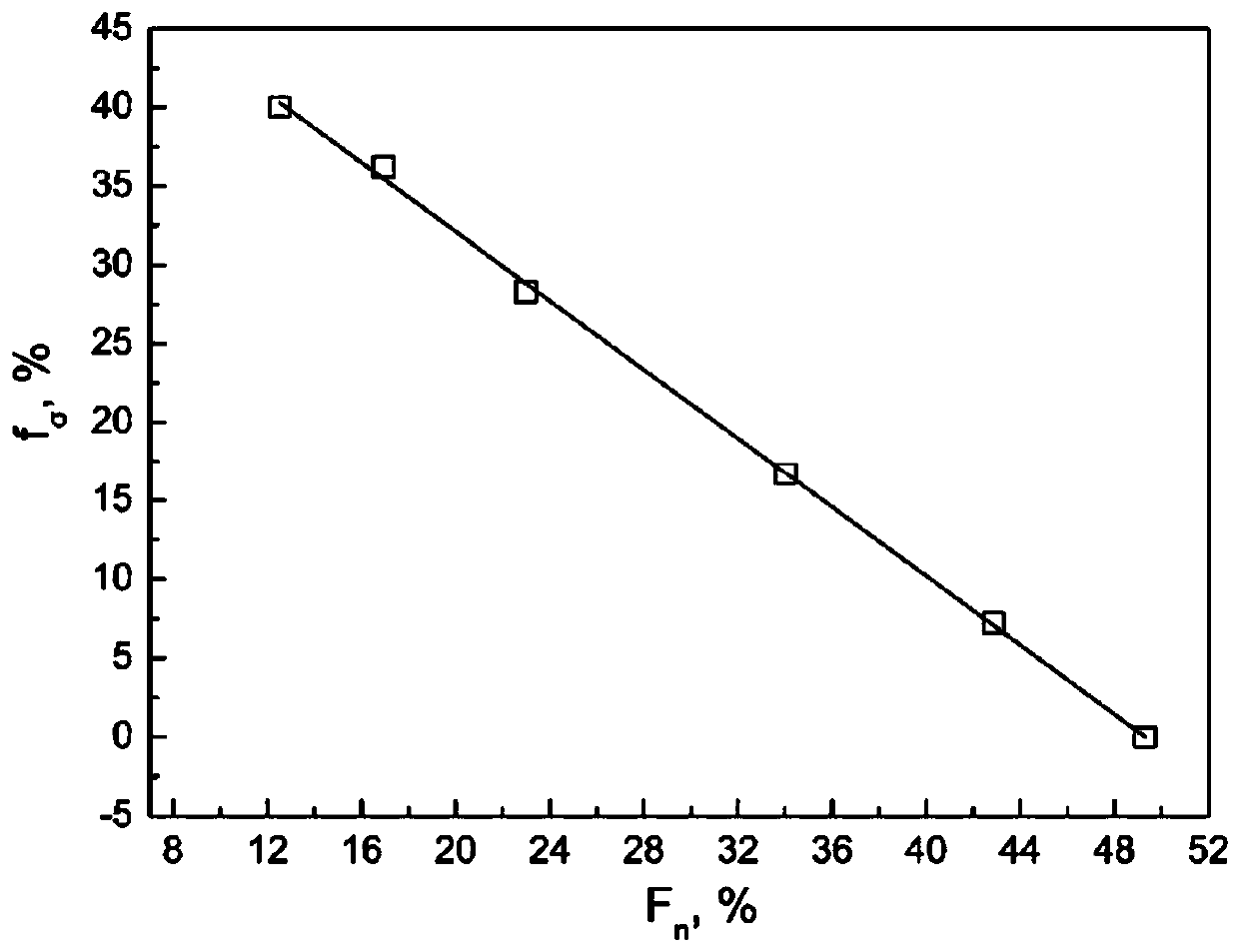

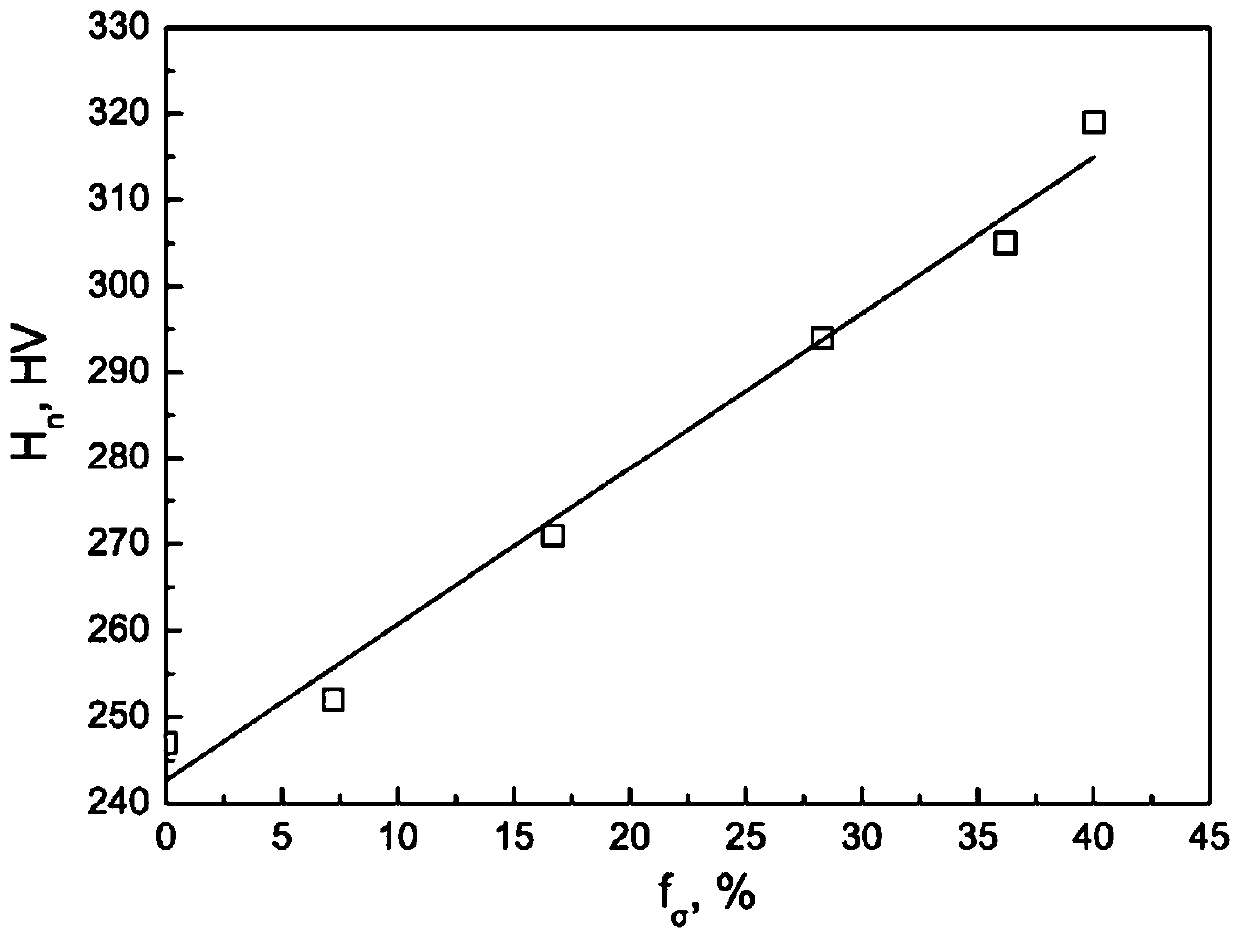

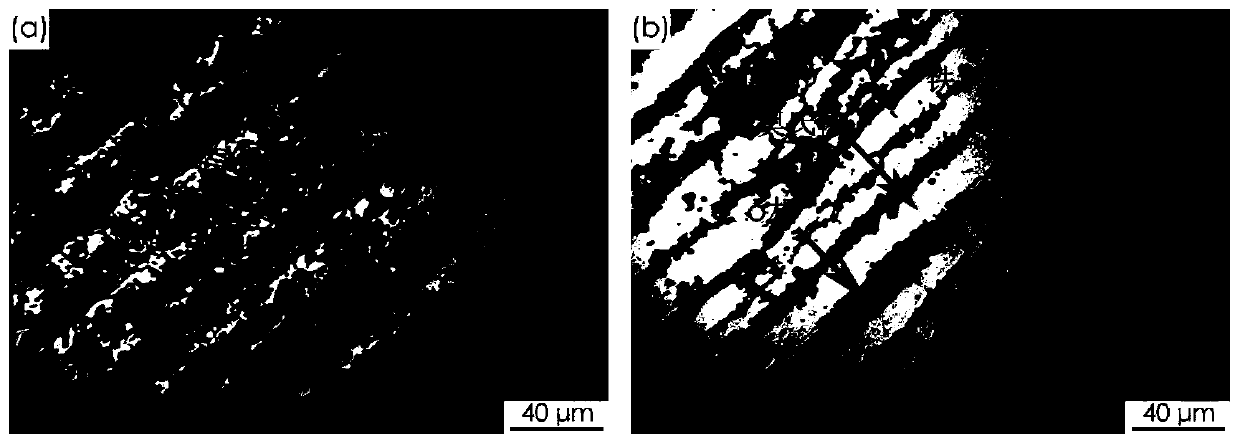

[0021] S1. Duplex stainless steel: Under the condition of 850°C, six kinds of duplex stainless steel with different σ phase contents with aging time of 0, 10, 30, 60, 90 and 120 minutes were obtained respectively, using sodium hydroxide electrolysis in ASTM A923 standard Etch duplex stainless steel and take metallographic photos. In this embodiment, the electrolytic etching solution is NaOH aqueous solution configured with a set weight ratio of sodium hydroxide (NaOH) and water, and the σ phase is quantitatively characterized by the number point method of ASTM E562 st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com