A method for leading out the cold end of the lanthanum hexaboride hollow cathode heating wire heating wire

A technology of hollow cathode and lanthanum hexaboride, which is applied in the direction of installation/support/configuration/insulation of discharge tube hollow cathode, discharge tube main electrode, electrode assembly, etc. Small size and other issues, to achieve the effect of increasing the equivalent conductive cross section, preventing heat loss, and good mechanical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

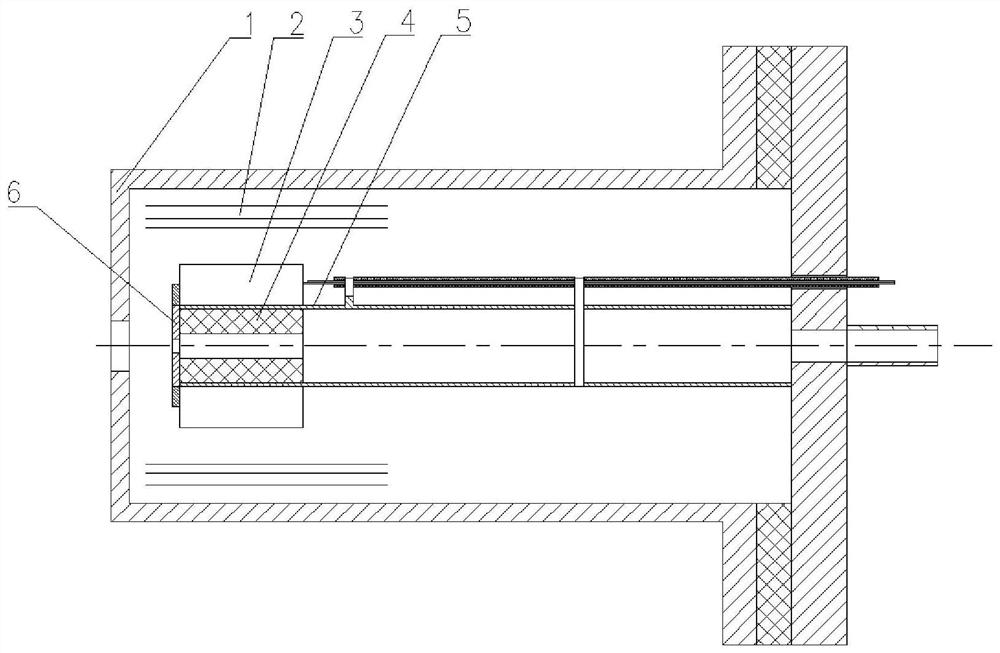

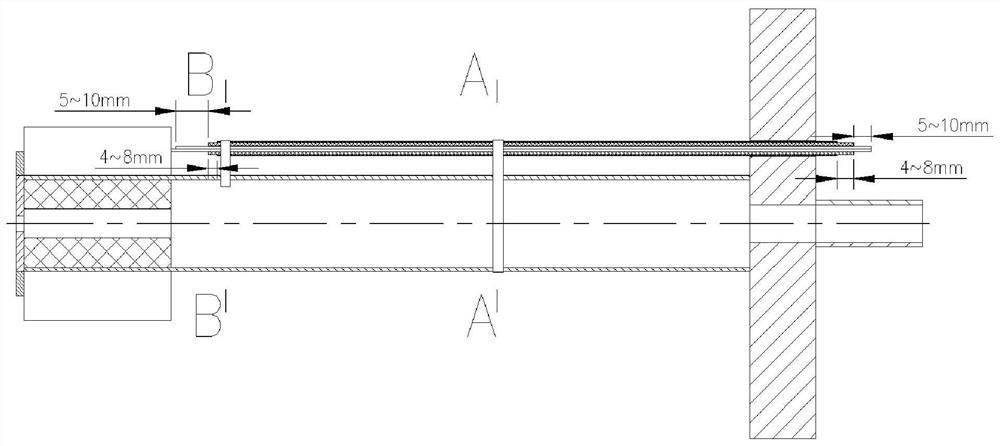

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

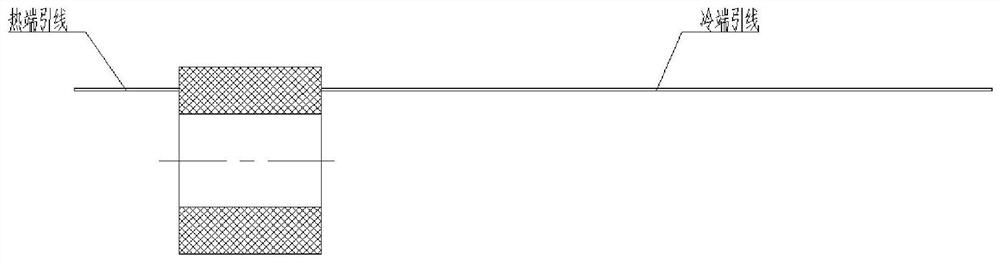

[0034] 1) The heater heating wire is a single heating wire with a uniform diameter, and the lead-out section of the cold end of the heater heating wire adopts a plurality of metal wires with a uniform diameter and the heater heating wire are arranged side by side; the metal wire and the heater heating wire used are the same One material, generally tungsten-rhenium heating wire; the diameter of the metal wire used is the same as that of the heater heating wire, generally φ0.3mm~φ0.5mm; the number of metal wires used should make the resistance of the lead-out section of the cold end and the heater generate heat The resistance ratio of the section is not more than 5%, so that the heating power is mainly generated in the emitting section of the heater, and the emission power of the lead-out section of the cold end is the smallest. Generally, 2 meta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com