A kind of spherical nanoporous silicon/silicon oxide/carbon composite material for lithium ion battery and preparation method thereof

A lithium-ion battery and nanoporous technology, which is applied in the fields of nanotechnology, nanotechnology, battery electrodes, etc. for materials and surface science, can solve the problems of further improvement of electrical properties, complicated preparation methods, and difficulty in industrialized production, etc. Achieve the effect of easy large-scale industrial production, simple process flow and good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

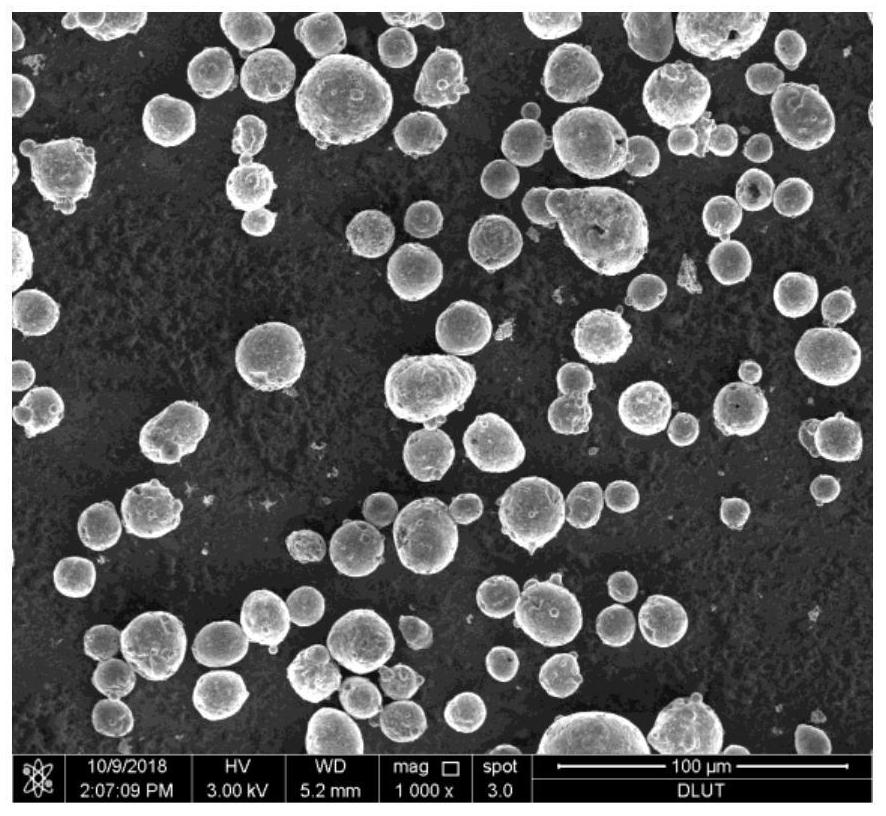

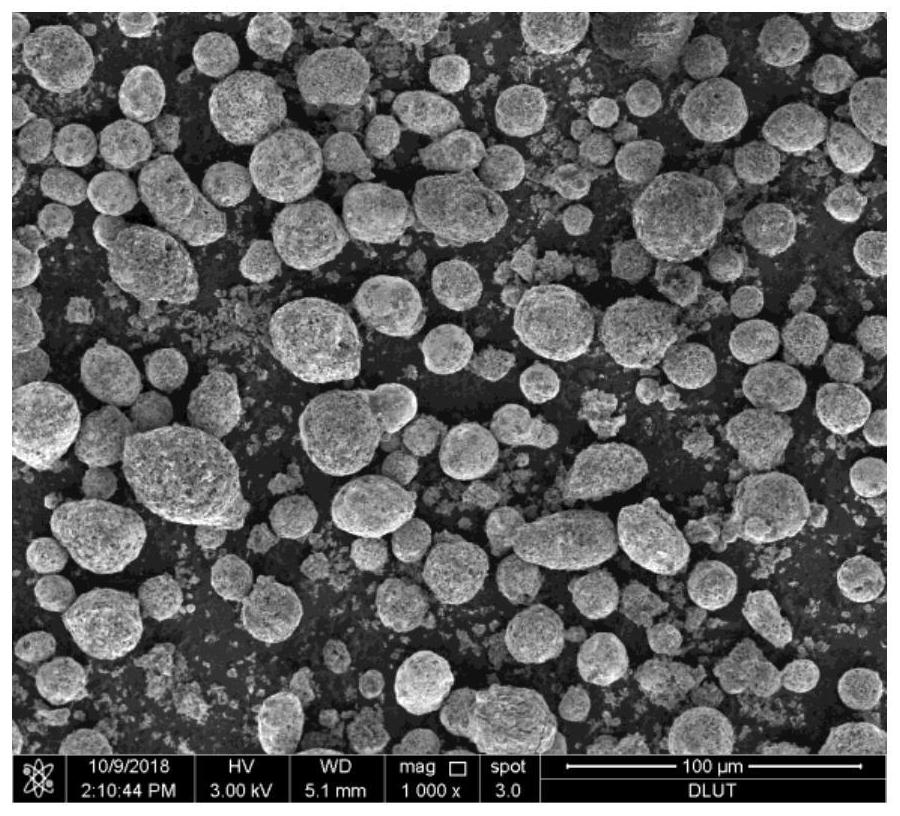

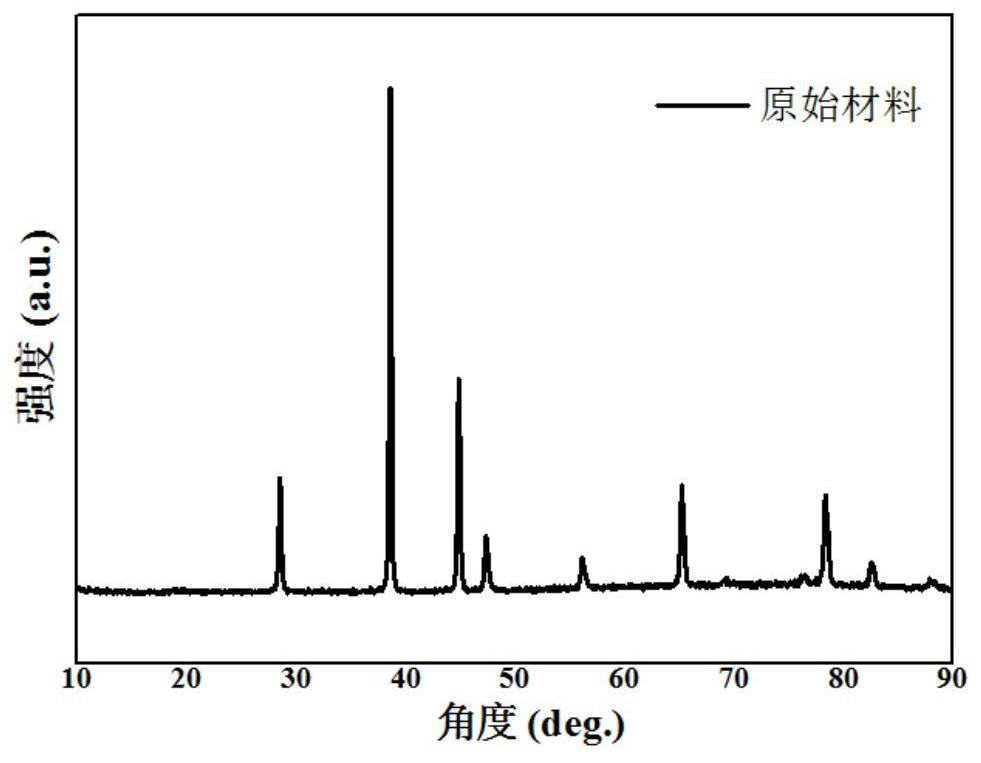

[0061]Using silicon / aluminum alloy powder as raw material, the D50 particle size is 20 μm; react the silicon / aluminum alloy powder with HCl solution with a mass concentration of 7%, stir gently for 10 hours under magnetic force, and the reaction temperature is 50°C, use deionized water and anhydrous The ethanol solution was quantitatively filtered 4 times to obtain a spherical nanoporous silicon precipitate; the above spherical nanoporous silicon precipitate was placed in a tube furnace for pre-oxidation treatment, the heating temperature was 120°C, and the pre-oxidation reaction time was 5h, so that the spherical nanoporous silicon precipitate A silicon oxide layer is coated on the surface of the porous silicon to improve the strength and structural stability of the nanoporous silicon structure. The pre-oxidized spherical nanoporous silicon and polyacrylonitrile were magnetically stirred at a mass ratio of 1:1 for 3 hours; the obtained homogeneous mixture of porous silicon / sil...

Embodiment 2

[0063] Using silicon / aluminum alloy powder as raw material, the D50 particle size is 20 μm; react the silicon / aluminum alloy powder with HCl solution with a mass concentration of 7%, stir gently for 10 hours under magnetic force, and the reaction temperature is 50°C, use deionized water and anhydrous The ethanol solution was quantitatively filtered 4 times to obtain a spherical nanoporous silicon precipitate; the above spherical nanoporous silicon precipitate was placed in a tube furnace for pre-oxidation treatment, the heating temperature was 360 ° C, and the pre-oxidation reaction time was 5 h to make the spherical nano-porous silicon precipitate A silicon oxide layer is coated on the surface of the porous silicon to improve the strength and structural stability of the nanoporous silicon structure. The pre-oxidized spherical nanoporous silicon and polyacrylonitrile were magnetically stirred at a mass ratio of 1:1 for 3 hours; the obtained homogeneous mixture of porous silicon...

Embodiment 3

[0066] Using silicon / aluminum alloy powder as raw material, the D50 particle size is 20 μm; the silicon / aluminum alloy powder is chemically reacted with HCl solution with a mass concentration of 7%, stirred gently by magnetic force for 10 hours, and the reaction temperature is 50°C. Quantitative suction filtration of water-ethanol solution 4 times to obtain spherical nanoporous silicon precipitate; put the above-mentioned spherical nanoporous silicon precipitate in a tube furnace for pre-oxidation treatment, the heating temperature is 480 ° C, the pre-oxidation reaction time is 5h, and the spherical A silicon oxide layer is coated on the surface of the nanoporous silicon, which is used to improve the strength and structural stability of the nanoporous silicon structure. The pre-oxidized porous silicon material and polyacrylonitrile were magnetically stirred for 3 hours at a mass ratio of 1:1; the obtained homogeneous mixture of porous silicon / silicon oxide / polymer was sintered ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com