Spherical nano porous silicon/metal composite negative electrode material and preparation method thereof

A nanoporous, metal composite technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of electrode material crushing and capacity decay, poor conductivity, large volume expansion, etc., to achieve easy Large-scale industrial production, good cycle performance, and the effect of improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

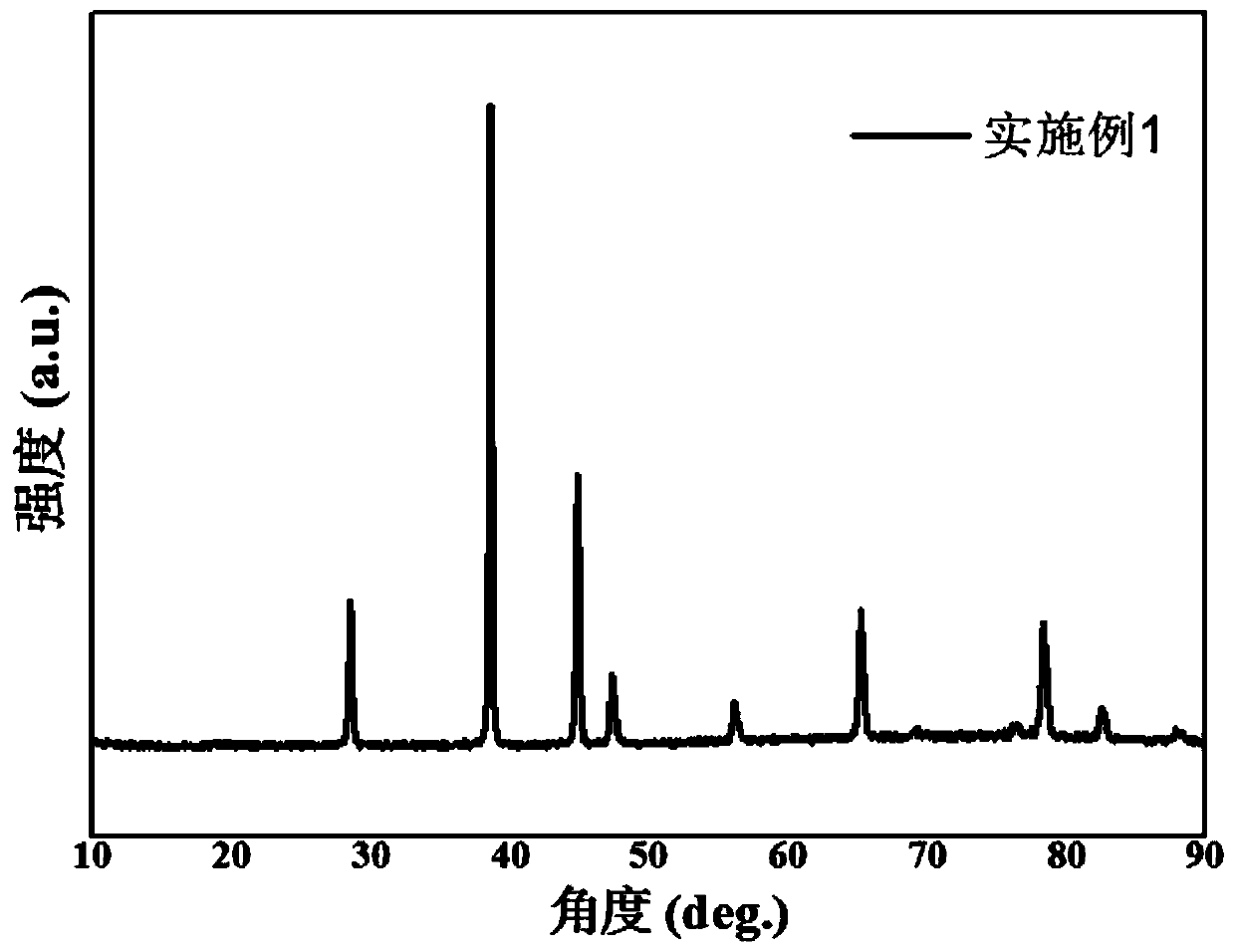

[0050] Using silicon / metal alloy powder as raw material, XRD such as image 3 As shown, the D50 particle size is 5 μm; the silicon / metal alloy powder is reacted with HCl solution with a molar concentration of 0.5M, stirred gently by magnetic force for 1 hour, and the reaction temperature is 25°C. Filter 4 times to obtain a spherical nanoporous silicon / alloy precipitate; place the above spherical nanoporous silicon / alloy precipitate in a vacuum drying oven for treatment at a drying temperature of 80°C for 12 hours to obtain a spherical nanoporous silicon / metal alloy The porosity of the powder is 25.76%, and the content of metal aluminum in the spherical nanoporous silicon / metal alloy powder is 75.81wt.%, and the spherical nanoporous silicon / metal alloy powder is ground with conductive carbon black and sodium carboxymethyl cellulose according to The mass ratio is 6:2:2, and poured into the solvent for grinding to obtain a uniformly mixed slurry; the slurry is coated on the metal...

Embodiment 2

[0052] Using silicon / metal alloy powder as raw material, the D50 particle size is 5 μm; react the silicon / metal alloy powder with HCl solution with a molar concentration of 0.5M, stir gently for 5 hours under magnetic force, and the reaction temperature is 50°C. After the reaction, use deionized water and Quantitative suction filtration of anhydrous ethanol solution 4 times to obtain a spherical nanoporous silicon / alloy precipitate; place the above spherical nanoporous silicon / alloy precipitate in a vacuum drying oven at a drying temperature of 80°C for 12 hours to obtain a spherical The porosity of the nanoporous silicon / metal alloy powder is 63.21%, and the content of metal aluminum in the spherical nanoporous silicon / metal alloy powder is 38.53wt.%. figure 2It can be seen that the shape of the prepared nanoporous silicon / metal composite negative electrode material is a sphere, and the morphology is mainly composed of bulk primary silicon and nanocluster eutectic silicon. T...

Embodiment 3

[0054] Using silicon / metal alloy powder as raw material, D50 particle size is 5 μm; react silicon / metal alloy powder with HCl solution with a molar concentration of 1.0M, stir gently for 1 hour under magnetic force, and the reaction temperature is 50°C. After the reaction, use deionized water and Quantitative suction filtration of anhydrous ethanol solution 4 times to obtain a spherical nanoporous silicon / alloy precipitate; place the above spherical nanoporous silicon / alloy precipitate in a vacuum drying oven at a drying temperature of 80°C for 12 hours to obtain a spherical The content of nanoporous silicon / metal alloy powder is 46.50%, and the content of metal aluminum in spherical nanoporous silicon / metal alloy powder is 64.07wt.%. Sodium cellulose is mixed according to the mass ratio of 6:2:2, and poured into a solvent for grinding to obtain a uniformly mixed slurry; the slurry is coated on a metal copper collector with a coating thickness of 100 μm, at 80°C Place in a vac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com