Preparation method for transparent substrate of brightness enhancement film

A technology of transparent substrate and brightening film, applied in the field of substrate, can solve the problem of raw material cost, thermal stability, tensile strength, yellowing resistance, dimensional variability and adhesion, which need to be improved, the impact of production cost fluctuations is large, and the threat to human health. and other problems, to achieve the effect of high elasticity, small curling degree and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

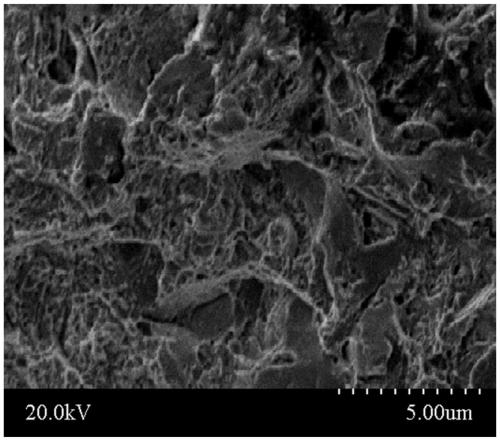

Image

Examples

preparation example Construction

[0042] The application provides a method for preparing a transparent base of a light enhancing film, which comprises the following steps:

[0043] 1) Boil O. sinensis with 5% NaOH and reflux for 2 days, then soak and stir in 2mol / L nitric acid for 2 days, and finally reflux with absolute ethanol at 30-50°C for 5 hours, filter, and wash the filter residue with deionized water to neutral;

[0044] 2) Add 0.1-10.0% (g / mL) azobisisobutyronitrile and 1.0-5.0% (g / mL) cyclohexane peroxide to 5.0-15.0% (g / mL) disodium edetate aqueous solution For ketones, transfer the filter residue to the above mixed solution at a material-to-liquid ratio of 1:20 (g / mL), adjust the pH of the solution to 10-12 and seal it, and heat it to 40-60°C with infrared heating at a speed of 60-180r / min. Stir for 12 hours, filter the product, and wash the filter residue with deionized water until neutral;

[0045] 3) Transfer the filter residue into an acetic acid solution with a pH of 3 according to the ratio...

Embodiment 1

[0051] This preferred embodiment provides a method for preparing a transparent base of a light enhancing film, which includes the following steps:

[0052] 1) The covered wings of O. chinensis are subjected to alkali boiling and reflux, acid leaching and stirring, and ethanol heating and reflux in sequence, and are filtered, and the filter residue is washed with deionized water until neutral;

[0053] 2) Add azobisisobutyronitrile and cyclohexanone peroxide to the aqueous solution of disodium edetate, transfer the filter residue to the above mixed solution, adjust the pH value of the solution to 11 and seal it, heat and continuously stir, and filter the product, The filter residue was washed with deionized water until neutral;

[0054] 3) The filter residue is transferred to the acetic acid solution, and the mixture is ground and centrifuged to get the supernatant;

[0055] 4) Dilute the supernatant 10 times with deionized water, evaporate part of the water, and make a hydrog...

Embodiment 2

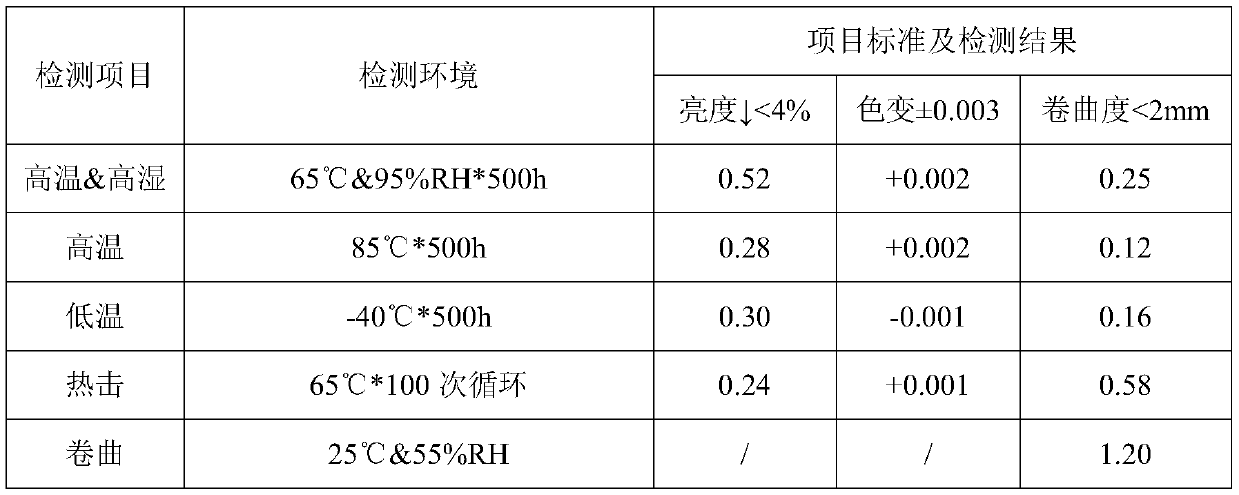

[0073] This preferred embodiment also provides a transparent substrate for a brightness enhancement film, which is characterized in that the transparent substrate for a brightness enhancement film is prepared by the method described in Example 1 above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com