Insulated wire

一种绝缘电线、绝缘层的技术,应用在绝缘电缆、绝缘体、绝缘导体等方向,能够解决价格使用范围限制等问题,达到价格低、阻燃性和耐热性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

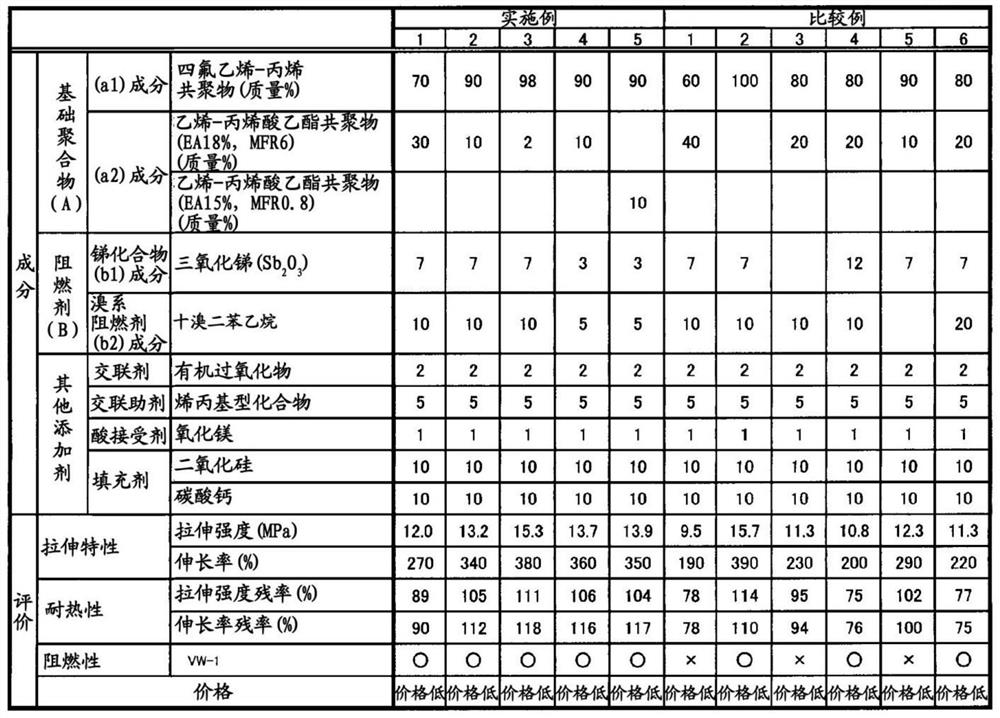

[0082] First, a fluoroelastomer composition for forming an insulating layer was prepared according to the blends shown in Table 1 below. Specifically, 70% by mass of the tetrafluoroethylene-propylene copolymer as the component (a1) and 30% by mass of the ethylene-ethyl acrylate copolymer (the amount of EA, MFR6) as the component (a2) were mixed to prepare As a base polymer (A), 7 parts by mass of an antimony compound (b1), 10 parts by mass of a brominated flame retardant (b2), 2 parts by mass of cross-linking agent (organic peroxide), 5 parts by mass of cross-linking aid (allylic compound), 1 part by mass of acid acceptor (magnesium oxide), 10 parts by mass of inorganic filler (silicon dioxide) , an inorganic filler (calcium carbonate), and these were kneaded with a roll to prepare the fluoroelastomer composition of Example 1.

[0083] Next, the prepared fluoroelastomer composition was extruded to a thickness of 0.4 mm on the outer periphery of a conductor (stranded tinned co...

Embodiment 2、3

[0088] In Examples 2 and 3, except that the mixing ratio of the component (a1) and the component (a2) was changed, a fluoroelastomer composition was prepared in the same manner as in Example 1, and an insulated wire was produced.

Embodiment 4

[0090] In Example 4, except that the compounding amount of the antimony compound (b1) was reduced from 7 parts by mass to 3 parts by mass, and the compounding amount of the brominated flame retardant (b2) was reduced from 10 parts by mass to 5 parts by mass, the same procedure as the implementation was carried out. Example 2 A fluoroelastomer composition was prepared in the same manner to produce an insulated wire.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com