Ceramic solar hot water energy storage device built by punching in deposit soil layer through pile driving and drawing machine

A technology for solar water heating and energy storage devices, which is applied in the directions of solar thermal energy, solar thermal power generation, solar thermal collectors, etc., can solve the problems of less than 10 years of service life, high maintenance costs, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

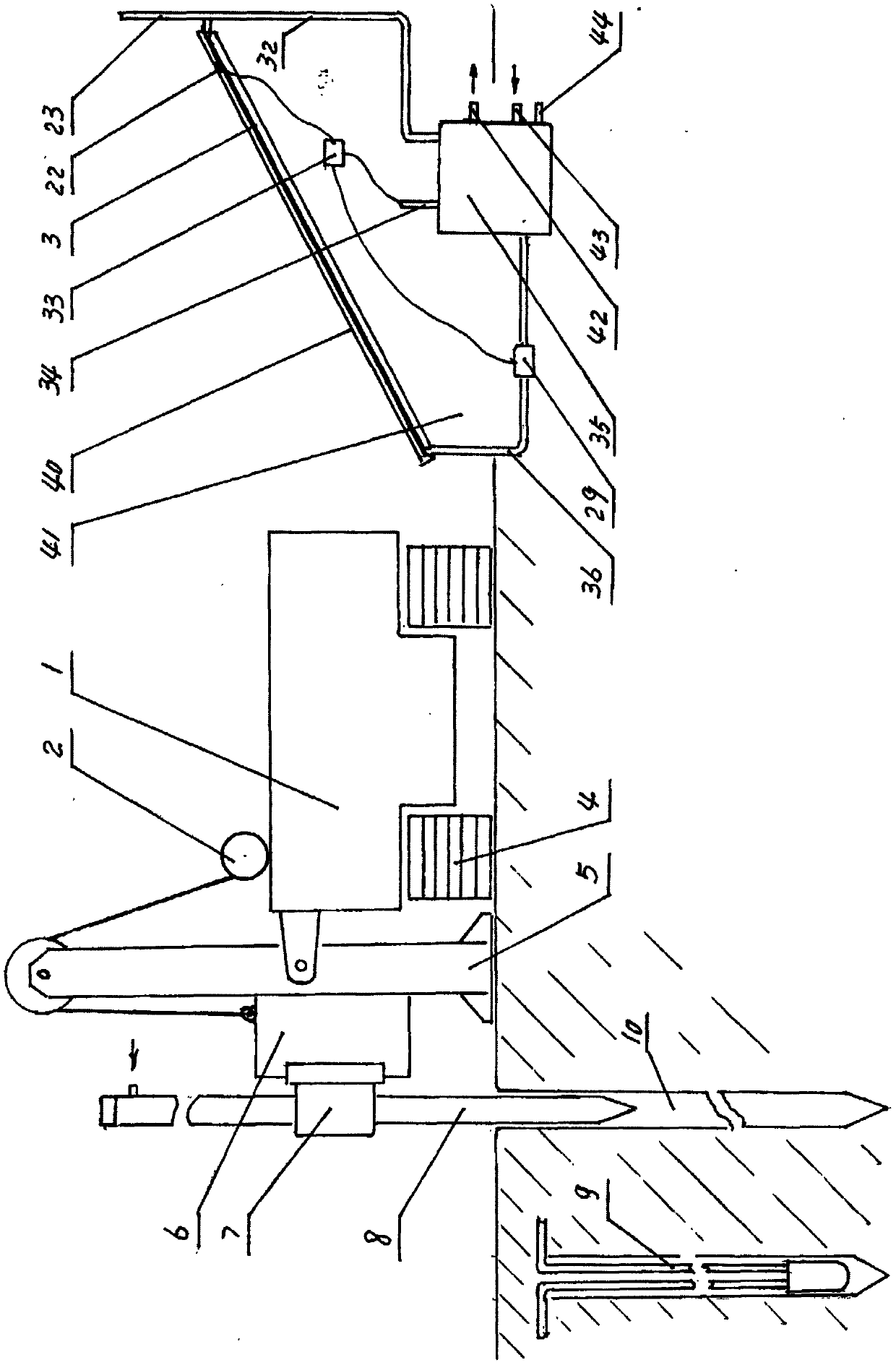

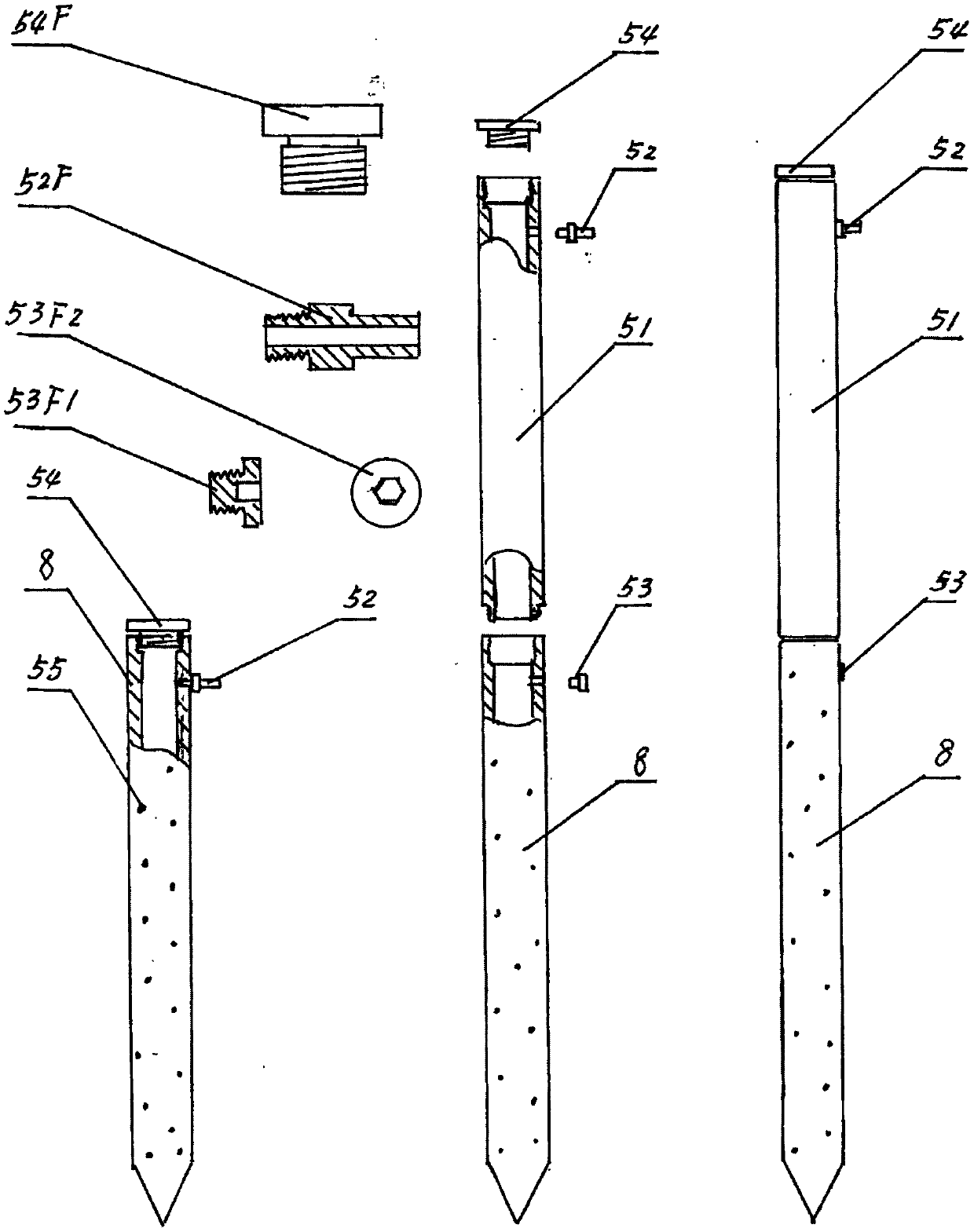

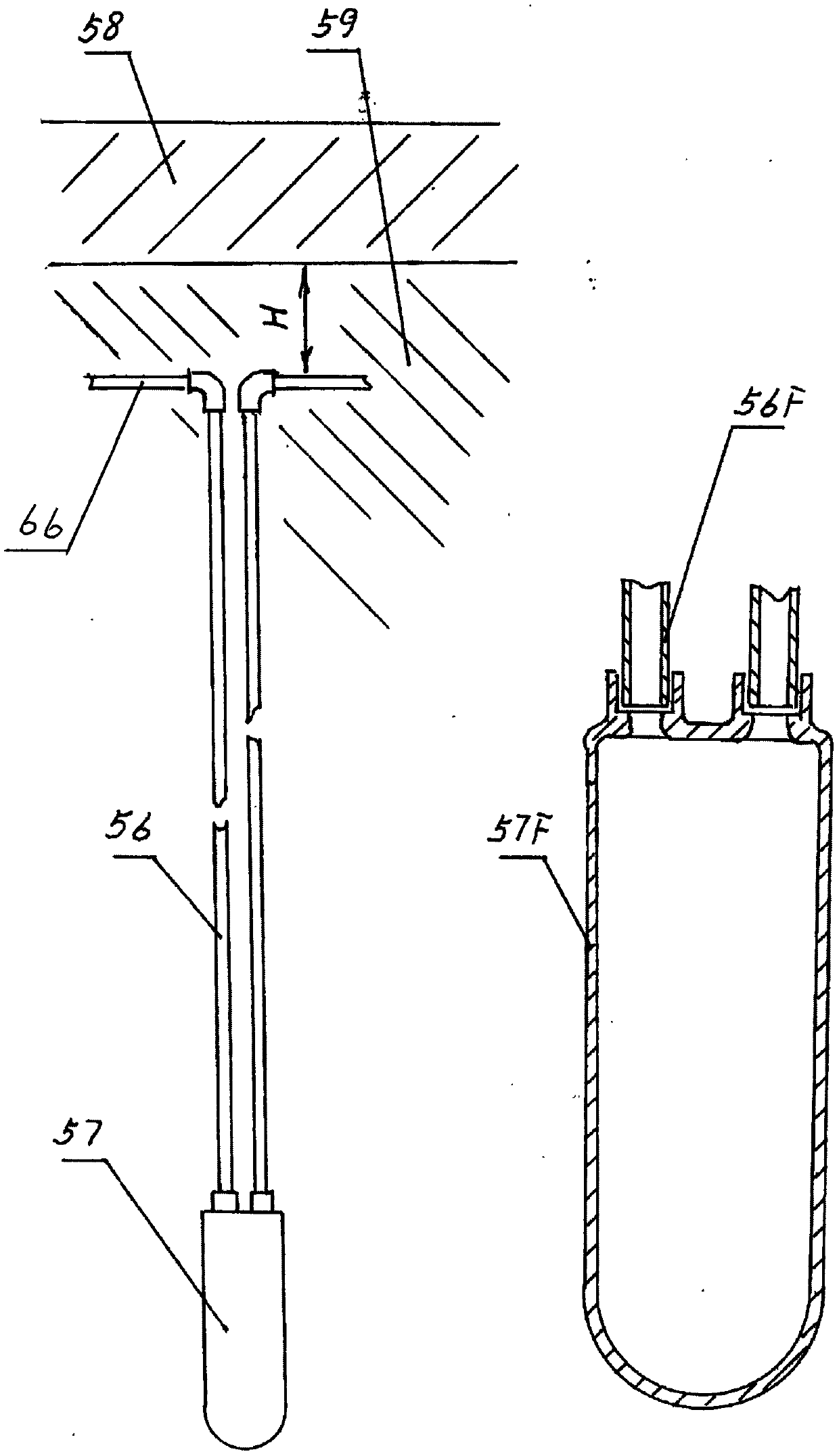

[0105] 1. A ceramic solar hot water inter-seasonal energy storage device was built on the accumulated soil layer of the Loess Plateau in Shaanxi with a pile driver. The ceramic solar hot water energy storage device covers an area of 12,000 square meters, with 800 holes and a hole depth of 30 m, to provide a room temperature greater than 10°C in winter for the greenhouse of 200,000 square meters and the pig house of 10,000 square meters. Each of the 10 pig houses is 1,000 square meters, built on top of the energy storage device, and the pig house uses a slope anchor pile Structural ceramic solar roof, with a total area of 10,000 square meters, and a total volume of 300 cubic meters of thermal insulation water tanks, which store solar energy in spring, summer and autumn into the energy storage device of the soil layer for use in winter. The clamper side of the high-frequency vibration hammer head of the pile pulling machine clamps a Φ100 mm thick-walled pointed steel pipe pil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com