Lamellar zinc-cobalt sulfide composite material based on MOFs, and preparation method and application thereof

A composite material and sulfide technology, applied in the direction of active material electrodes, electrochemical generators, electrical components, etc., can solve the problems of large material volume changes, poor structural stability, and reduced cycle performance, and increase the contact area , enhanced conductivity, high specific capacity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

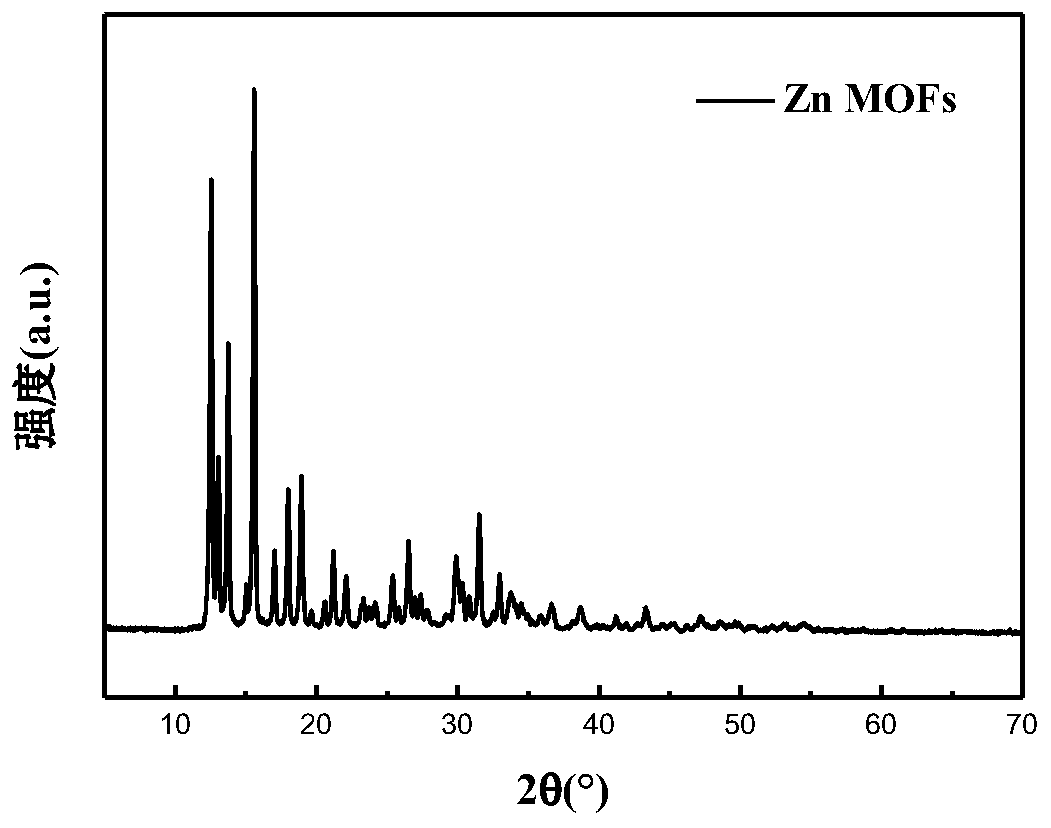

[0031] A method for preparing a MOFs-based lamellar zinc-cobalt sulfide composite material, comprising the following steps:

[0032] (1) Dissolve 0.33g of zinc nitrate hexahydrate into 90mL of deionized water, and then add the solution to 90mL of an aqueous solution containing 0.985g of 2-methylimidazole under stirring (the moles of 2-methylimidazole and zinc nitrate hexahydrate ratio of 10.814:1), stirred for 24 hours to obtain a white precipitate, centrifuged, washed 5 times with distilled water, and dried in air at 80°C for 12 hours;

[0033] (2) Add 0.08g white Zn MOFs to 25mL ethanol solution containing 0.08g cobalt nitrate hexahydrate (the mass ratio of cobalt nitrate hexahydrate and white Zn MOFs is 1:1), the solution is ultrasonicated for 20min, stirred for 10min, then centrifuged 1. Dry in ambient air at 80°C for 12h to obtain pinkish purple powder Co / Zn MOFs;

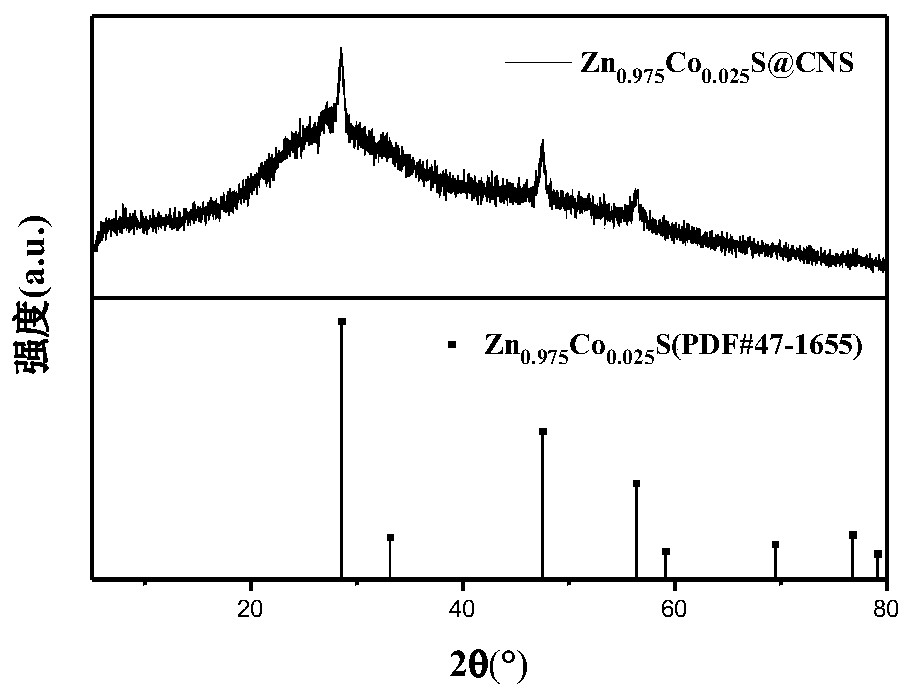

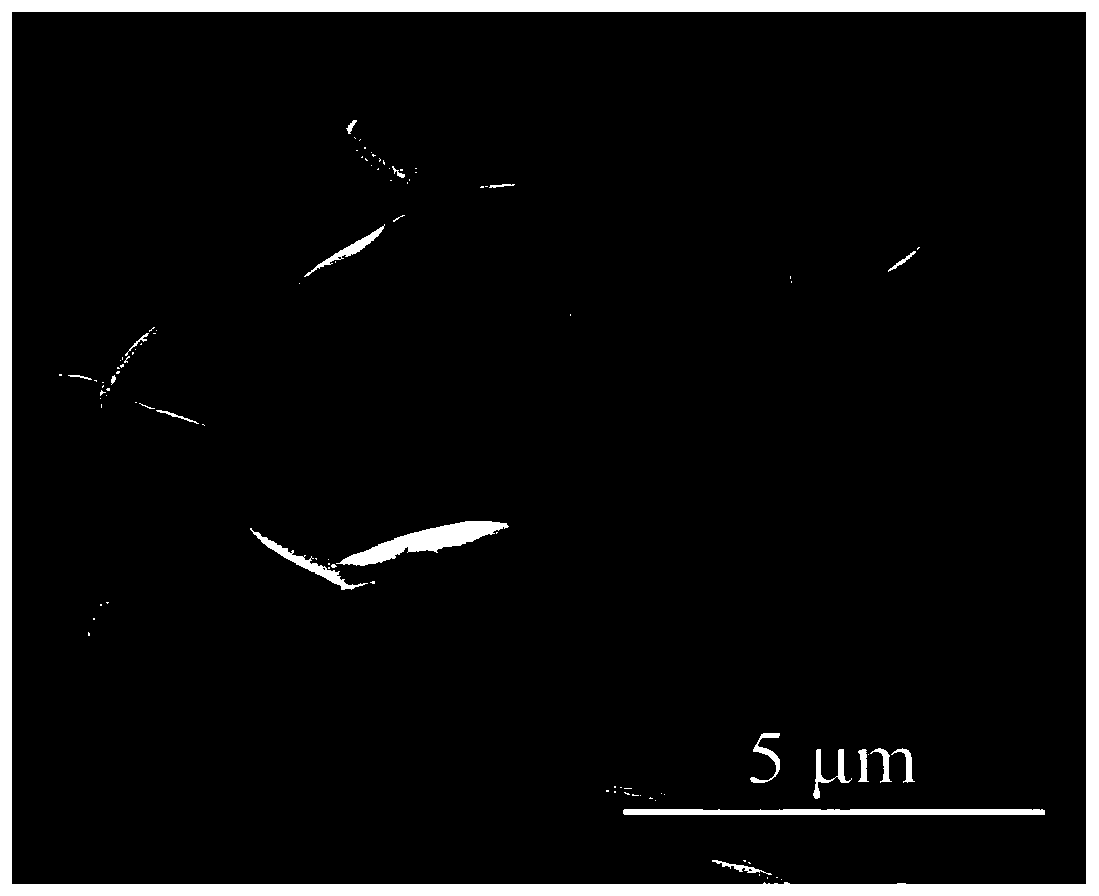

[0034] (3) Place the Co / Zn MOFs in (2) in a ceramic crucible at 700 °C, N 2 In the atmosphere, the heatin...

Embodiment 2

[0043] A preparation method of MOFs-based lamellar zinc-cobalt sulfide composite material Z2, comprising the following steps:

[0044] (1) Dissolve 0.33g of zinc nitrate hexahydrate into 90mL of deionized water, and then add the solution to 90mL of an aqueous solution containing 0.455g of 2-methylimidazole under stirring (the moles of 2-methylimidazole and zinc nitrate hexahydrate ratio of 5:1), stirred for 24 hours to obtain a white precipitate, centrifuged, washed 5 times with distilled water, and dried in ambient air at 80°C for 12 hours;

[0045] (2) Add 0.08g white Zn MOFs to 25mL ethanol solution containing 0.08g cobalt nitrate hexahydrate (the mass ratio of cobalt nitrate hexahydrate and white Zn MOFs is 1:1), the solution is ultrasonicated for 20min, stirred for 10min, and then centrifuged , dried in ambient air at 80°C for 12h to obtain pinkish purple powder Co / Zn MOFs;

[0046] (3) Place the Co / Zn MOFs in (2) in a ceramic crucible at 700 °C, N 2 In the atmosphere, ...

Embodiment 3

[0050] A preparation method of MOFs-based lamellar zinc-cobalt sulfide composite material Z3, comprising the following steps:

[0051] (1) Dissolve 0.33g of zinc nitrate hexahydrate into 90mL of deionized water, and then add the solution to 90mL of an aqueous solution containing 1.822g of 2-methylimidazole under stirring (the moles of 2-methylimidazole and zinc nitrate hexahydrate ratio of 20:1), stirred for 24 hours to obtain a white precipitate, centrifuged, washed 5 times with distilled water, and dried in ambient air at 80°C for 12 hours;

[0052] (2) Add 0.08g of white Zn MOFs to 25mL ethanol solution containing 0.08g of cobalt nitrate hexahydrate, ultrasonicate the solution for 20min, stir for 10min, then centrifuge, and dry in ambient air at 80°C for 12h to obtain pink-purple powder Co / ZnMOFs;

[0053] (3) Place the Co / Zn MOFs in (2) in a ceramic crucible at 700 °C, N 2 In the atmosphere, the heating rate is 2°C / min, calcined for 2 hours, and black powder is obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com