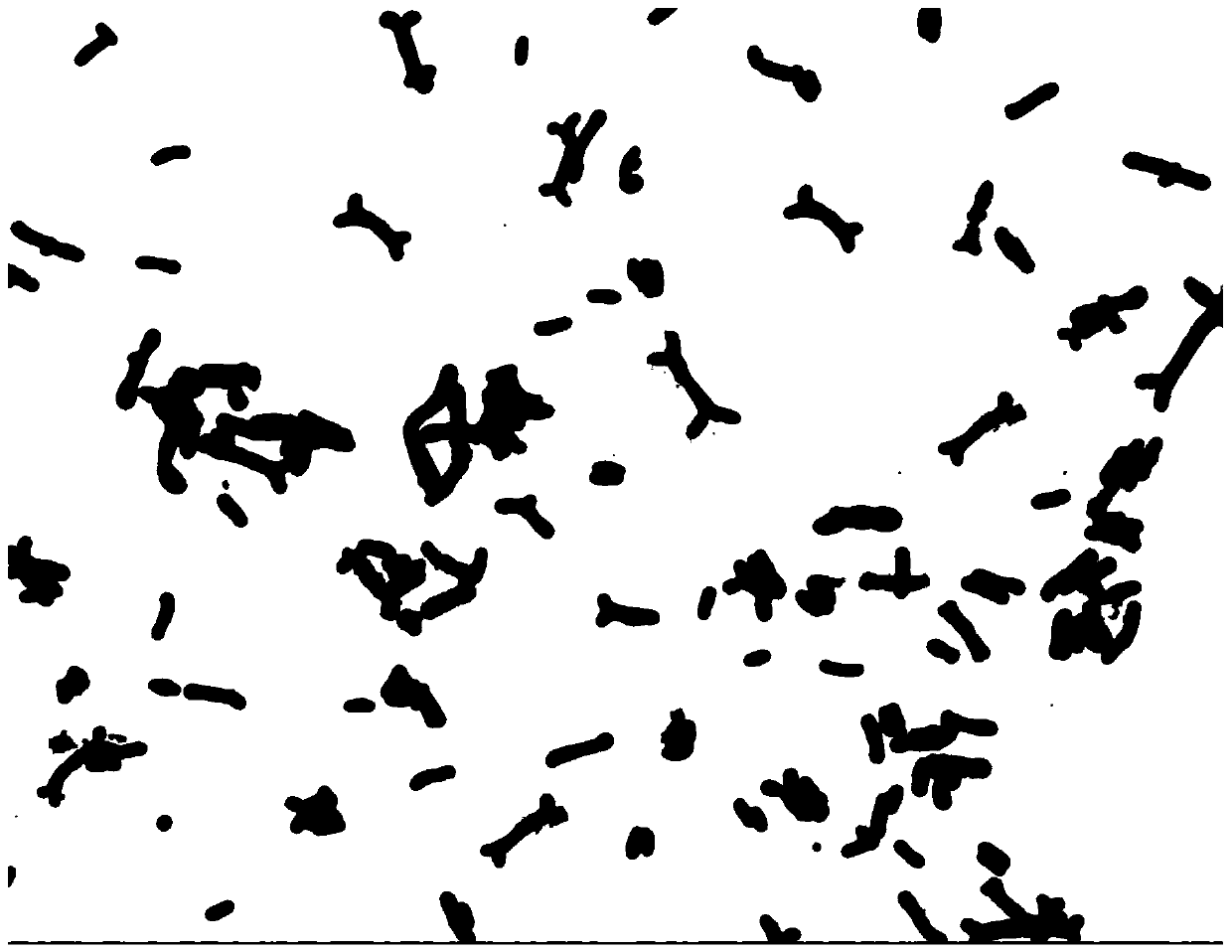

Micro-concentrated probiotic yoghurt rich in bifidobacterium lactis and preparation method thereof

A technology of bifidobacteria lactis and probiotics, applied in the directions of bifidobacteria, lactobacillus, dairy products, etc., can solve the problems of high price and lack of functional effect, and achieve excellent texture and taste, dense taste, Creamy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A kind of micro-concentrated probiotic yogurt rich in bifidobacterium lactis, which is obtained by mixing and fermenting the following components: resistant dextrin 2‰, soybean peptide powder 5‰, yeast extract 0.3‰, milk bifidobacteria Bacillus 2×10 7 CFU / g, Streptococcus thermophilus 2×10 7 CFU / g, Lactobacillus bulgaricus 4×10 5 CFU / g, the balance of raw milk is added to 100%.

[0041] The preparation method of this yogurt comprises the following steps:

[0042] 1. Heat raw milk to 50°C;

[0043] 2. Premix the resistant dextrin (2‰), soybean peptide powder (5‰) and yeast extract (0.3‰) and then slowly add it to the above raw milk, stir evenly to dissolve the material completely;

[0044] 3. Raise the temperature of the mixed material liquid to 68°C, and then perform degassing. The degassing pressure is -0.055Mpa, and the online detection of dissolved oxygen is about 0.5ppm;

[0045] 4. Filter the degassed feed liquid and then homogenize it. The homogenization temp...

Embodiment 2

[0053] A micro-concentrated probiotic yogurt rich in Bifidobacterium lactis, which is obtained by mixing and fermenting the following components: resistant dextrin 5‰, soybean peptide powder 2‰, yeast extract 0.5‰, lactobacillus Bacillus 3×10 7 CFU / g, Streptococcus thermophilus 2×10 7 CFU / g, Lactobacillus bulgaricus 3×10 5 CFU / g, the balance of raw milk is added to 100%.

[0054] The preparation method of this yogurt comprises the following steps:

[0055] 1. Heat raw milk to 50°C;

[0056] 2. Premix the resistant dextrin (5‰), soybean peptide powder (2‰) and yeast extract (0.5‰) and then slowly add it to the above raw milk, stir evenly to dissolve the material completely;

[0057] 3. Raise the temperature of the mixed material liquid to 68°C, and then degas it. The degassing pressure is -0.055Mpa, and the online detection of dissolved oxygen is about 0.1ppm;

[0058] 4. Filter the degassed feed liquid and then homogenize it. The homogenization temperature is 65°C, and th...

Embodiment 3

[0066] A micro-concentrated probiotic yogurt rich in bifidobacterium lactis, which is obtained by mixing and fermenting the following components: resistant dextrin 4‰, soybean peptide powder 4‰, yeast extract 0.6‰, milk bifidobacteria Bacteria 4×10 7 CFU / g, Streptococcus thermophilus 1×10 7 CFU / g, Lactobacillus bulgaricus 2×10 5 CFU / g, the balance of raw milk is added to 100%.

[0067] The preparation method of this yogurt comprises the following steps:

[0068] 1. Heat raw milk to 50°C;

[0069] 2. Premix the resistant dextrin (4‰), soybean peptide powder (4‰) and yeast extract (0.6‰) and then slowly add it to the above raw milk, stir evenly to dissolve the material completely;

[0070] 3. Raise the temperature of the mixture liquid to 68°C, and then perform degassing. The degassing pressure is -0.055Mpa, and the online detection of dissolved oxygen is about 2ppm;

[0071] 4. Filter the degassed feed liquid and then homogenize it. The homogenization temperature is 65°C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com