Activating and sintering preparation method of a metal composite porous membrane tube

A metal composite, activated sintering technology, applied in chemical instruments and methods, membrane, membrane technology and other directions, can solve the problems of low service life of FeAl-based filter elements, high preparation cost of metal microporous membrane, and easy condensation of coal tar. Achieve the effect of easing the contradiction between high permeability and high filtration accuracy, prolonging stable operation time and improving the overall filtration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

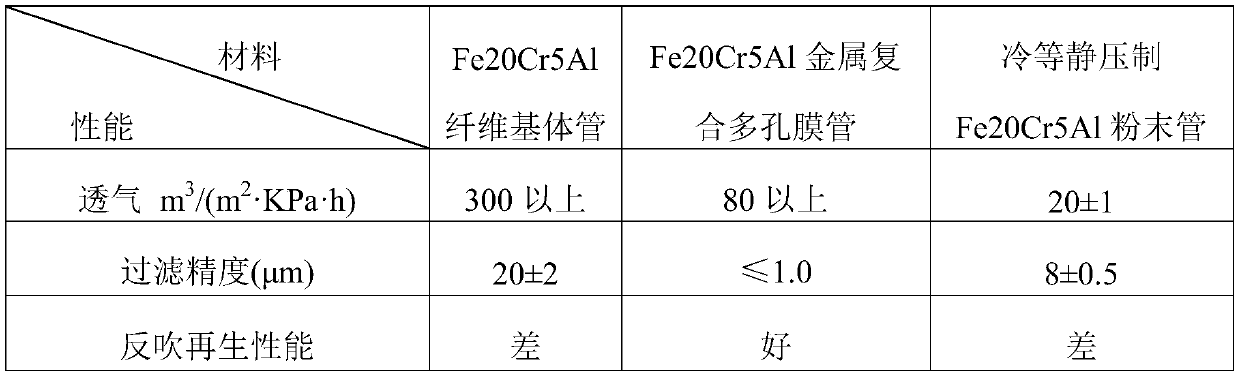

[0024] In this specific example 1, a Fe20Cr5Al fiber tube with a filtration accuracy of 20 μm, a diameter of 80 mm, a height of 500 mm, and a thickness of about 2 mm was used as the base tube (provided by the Northwest Nonferrous Metal Research Institute) to prepare the Fe20Cr5Al composite porous membrane tube.

[0025] The invention relates to an activation sintering preparation method of a metal composite porous membrane tube, which comprises the following steps:

[0026] Step 1. Prepare metal powder slurry.

[0027] Using commercially available Fe20Cr5Al metal powder with a particle size of 20-30 μm or above 80% is added to an organic solvent, and then uniformly stirred with a stirrer for 30 minutes to prepare a metal powder slurry. Wherein, the weight ratio of the Fe20Cr5Al metal powder to the organic solvent is 3:1, and the organic solvent is selected from one of polyvinyl alcohol, terpineol, carbon tetrachloride or glycerin.

[0028] Step two, spraying of metal powder slurry.

[...

Embodiment 2

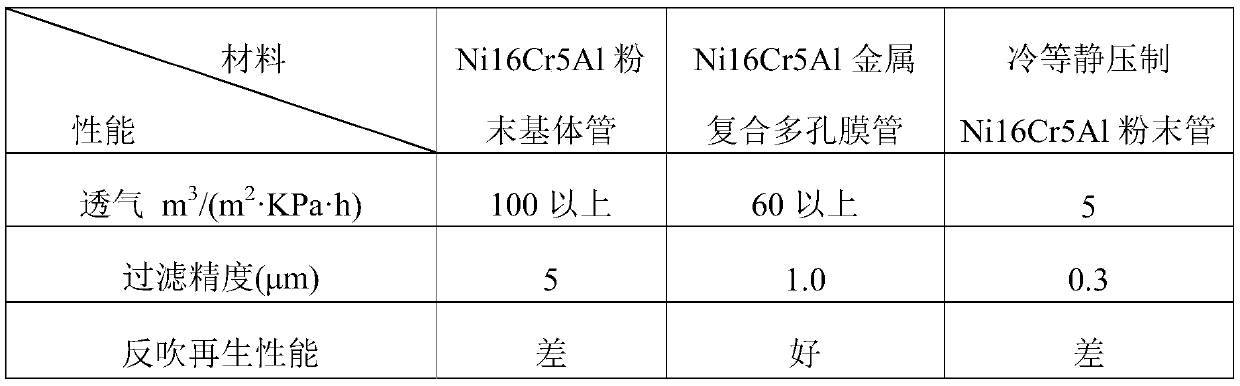

[0039] In this specific example 2, a Ni16Cr5Al powder tube with a filtration accuracy of 5 μm, a diameter of 60 mm, a height of 1000 mm, and a thickness of about 2.5 mm was used as the base tube (provided by the Northwest Nonferrous Metal Research Institute) to prepare a Ni16Cr5Al composite porous membrane tube.

[0040] The invention relates to an activation sintering preparation method of a metal composite porous membrane tube, which comprises the following steps:

[0041] Step 1. Prepare metal powder slurry.

[0042] The commercially available Ni16Cr5Al metal powder with a particle size of 0.2-22 μm or more is used, added to the organic solvent, and then uniformly stirred with a stirrer for 40 minutes to prepare a metal powder slurry. Wherein, the weight ratio of the Ni16Cr5Al metal powder to the organic solvent is 1:1, and the organic solvent is selected from one of polyvinyl alcohol, terpineol, carbon tetrachloride or glycerin.

[0043] Step two, spraying of metal powder slurry. ...

Embodiment 3

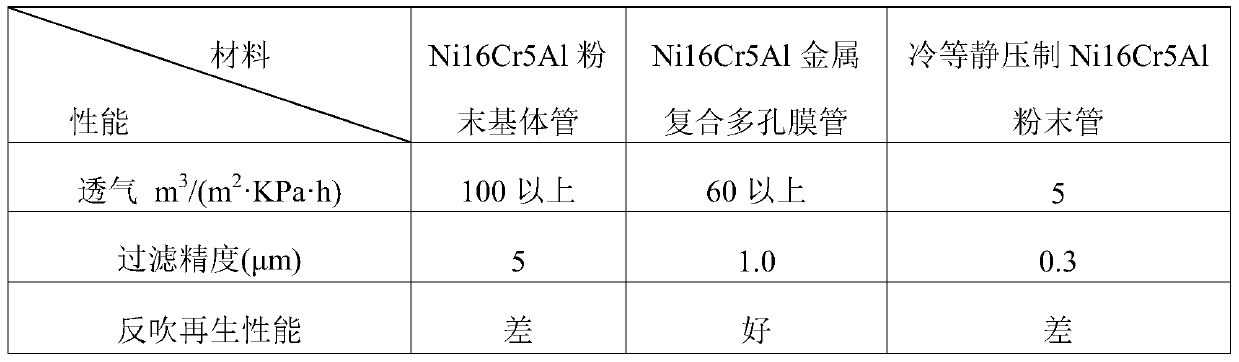

[0054] In this specific example 3, a Ni16Cr5Al powder tube with a filtration accuracy of 5 μm, a diameter of 60 mm, a height of 1000 mm, and a thickness of about 2.5 mm was used as the base tube (provided by the Northwest Nonferrous Metal Research Institute) to prepare a Ni16Cr5Al composite porous membrane tube.

[0055] The invention relates to an activation sintering preparation method of a metal composite porous membrane tube, which comprises the following steps:

[0056] Step 1. Prepare metal powder slurry.

[0057] The commercially available Ni16Cr5Al metal powder with a particle size of 0.2-22 μm or more is used, added to the organic solvent, and then uniformly stirred with a stirrer for 40 minutes to prepare a metal powder slurry. Wherein, the weight ratio of the Ni16Cr5Al metal powder to the organic solvent is 1:1, and the organic solvent is selected from one of polyvinyl alcohol, terpineol, carbon tetrachloride or glycerin.

[0058] Step two, spraying of metal powder slurry. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com