P-6 type basic yttrium carbonate/carbon composite material, and preparation method and application thereof

A technology of carbon composite materials and composite materials, applied in chemical instruments and methods, other chemical processes, water/sewage treatment, etc., can solve the problems of inability to realize large-scale production and practical application, low crystallinity of products, small specific surface area, etc. problem, to achieve the effect of simple and efficient synthesis method, low preparation conditions and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

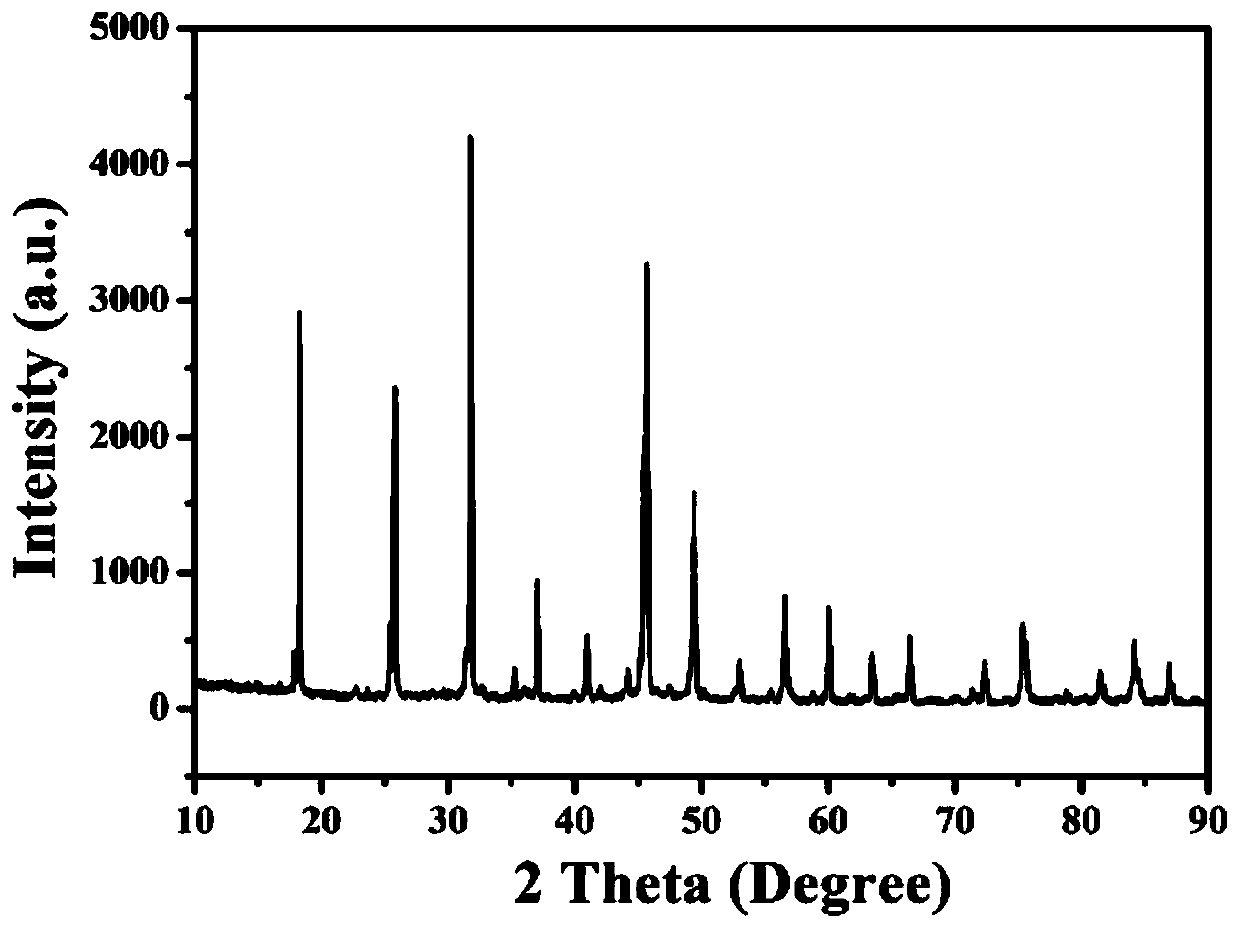

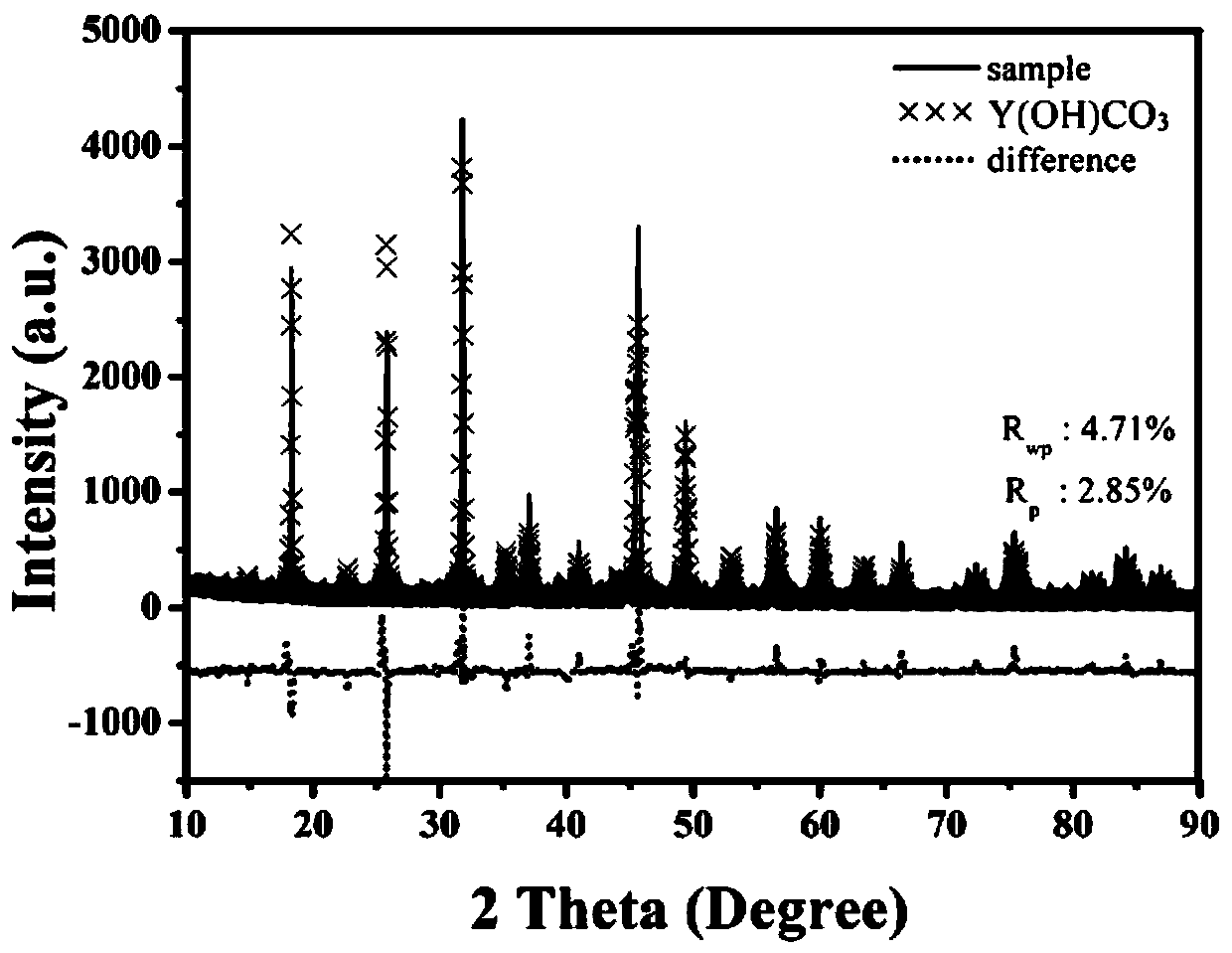

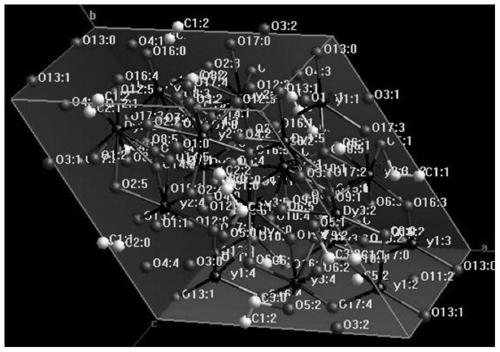

Method used

Image

Examples

Embodiment 1

[0022] (1) Preparation of yttrium-based coordination polymer: 0.5mmol Y(NO 3 ) 3 ·6H 2 O and 1.5mmol oxalic acid were dissolved in 40ml of DMF solvent, and reacted in a household microwave reaction device for 15min with a power of 240W;

[0023] (2) Treatment of the yttrium-based coordination polymer: the yttrium-based coordination polymer obtained by the microwave reaction was alternately washed with distilled water and ethanol, and dried in a vacuum oven at 60°C;

[0024] (3) Preloading of the yttrium-based coordination polymer: the dried yttrium-based coordination polymer is packed into Mo for preloading, and the loading pressure is 10MPa;

[0025] (4) High-temperature and high-pressure reaction: The pre-pressed yttrium-based coordination polymer is reacted in a domestic hinged 1400-ton six-sided top press, and the pressure is first raised to 3GPa at a rate of 0.3GPa / min, and the pressure is stabilized Then, raise the temperature to 1000°C at a rate of 100°C / min, keep it...

Embodiment 2

[0028] (1) Preparation of yttrium-based coordination polymer: 0.1mmol Y(NO 3 ) 3 ·6H 2 O and 0.3 mmol pimelic acid were dissolved in 40 ml DMF and H 2 In a mixed solvent of O, react in a household microwave reaction device for 20min with a power of 240W;

[0029] (2) Treatment of the yttrium-based coordination polymer: the yttrium-based coordination polymer obtained by the microwave reaction was alternately washed with distilled water and ethanol, and dried in a vacuum oven at 60°C;

[0030] (3) Preloading of the yttrium-based coordination polymer: the dried yttrium-based coordination polymer is packed into Mo for preloading, and the loading pressure is 5MPa;

[0031] (4) High-temperature and high-pressure reaction: The pre-pressed yttrium-based coordination polymer is reacted in a domestic hinged 1400-ton six-sided top press, and the pressure is first raised to 5GPa at a rate of 0.5GPa / min, and the pressure is stabilized Then, raise the temperature to 400°C at a rate of 5...

Embodiment 3

[0034] (1) Preparation of yttrium-based coordination polymer: 0.5mmol Y(NO 3 ) 3 ·6H 2 O and 1.5mmol oxalic acid were dissolved in 40ml of DMF solvent, and reacted in a household microwave reaction device for 15min with a power of 240W;

[0035] (2) Treatment of the yttrium-based coordination polymer: the yttrium-based coordination polymer obtained by the microwave reaction was alternately washed with distilled water and ethanol, and dried in a vacuum oven at 60°C;

[0036] (3) Preloading of the yttrium-based coordination polymer: the dried yttrium-based coordination polymer is packed into Mo for preloading, and the loading pressure is 20MPa;

[0037] (4) High-temperature and high-pressure reaction: The pre-pressed yttrium-based coordination polymer is reacted in a domestic hinged 1400-ton six-sided top press, and the pressure is first raised to 3GPa at a rate of 0.3GPa / min, and the pressure is stabilized Then, raise the temperature to 400°C at a rate of 100°C / min, keep it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com