A method for separating sulfonium salts from petroleum matrix

A technology for petroleum and sulfonium salts, applied in the field of separation of sulfonium salts, can solve the problems of repeated precipitation and incomplete precipitation, and achieve the effects of simple operation, avoiding incomplete precipitation and high separation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

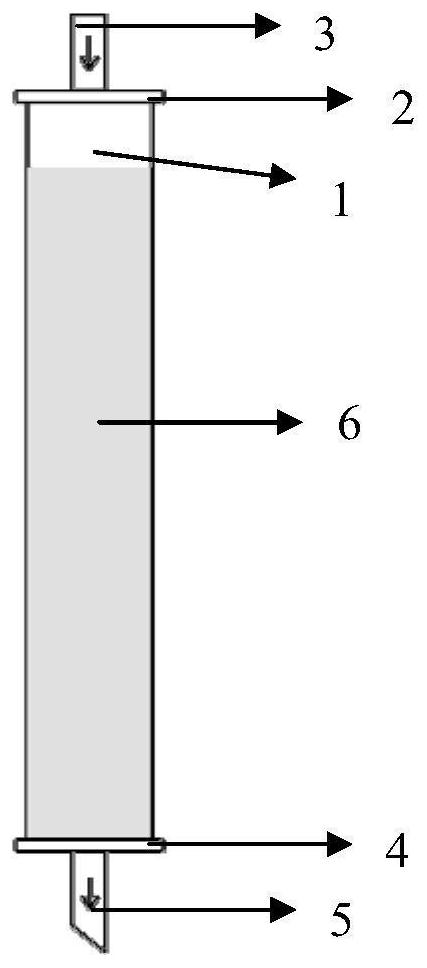

[0032] This embodiment provides a method for separating sulfonium salts from petroleum substrates, wherein the method is realized by using a solid-phase chromatographic column for separating sulfonium salts from petroleum substrates. The structural representation of the solid-phase chromatographic column is as follows figure 1 shown, from figure 1 As can be seen from the figure, the solid-phase chromatographic column includes a column body 1 and two column caps (upper column cap 2 and lower column cap 4) respectively arranged at the two ends of the column body; the upper column cap 2 and the lower column cap 4 respectively An inlet and an outlet are provided; the inlet and the outlet are respectively connected with an inlet pipeline 3 and an outlet pipeline 5;

[0033] The cylinder 1 is used to contain the compacted solid phase packing layer 6 .

[0034] In this embodiment, the cylinder 1 has a length of 300 mm, an inner diameter of 25 mm, and an outer diameter of 30 mm.

[...

Embodiment 2

[0045] This embodiment provides a method for separating sulfonium salts from petroleum substrates, wherein the method is realized by using a solid-phase chromatographic column for separating sulfonium salts from petroleum substrates. The structural representation of the solid-phase chromatographic column is as follows figure 1 shown, from figure 1 As can be seen from the figure, the solid-phase chromatographic column includes a column body 1 and two column caps (upper column cap 2 and lower column cap 4) respectively arranged at the two ends of the column body; the upper column cap 2 and the lower column cap 4 respectively An inlet and an outlet are provided; the inlet and the outlet are respectively connected with an inlet pipeline 3 and an outlet pipeline 5;

[0046] The cylinder 1 is used to contain the compacted solid phase packing layer 6 .

[0047] In this embodiment, the cylinder 1 has a length of 300 mm, an inner diameter of 25 mm, and an outer diameter of 30 mm.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com