Magnetic nanoparticle ferroferric oxide as well as preparation method and application thereof

A technology of magnetic nanoparticles and ferric oxide, applied in the field of nanomaterials, can solve the problems of no visible light catalytic performance, unfavorable industrialization, high preparation cost, and achieve excellent visible light catalytic performance and adsorption performance, not easy to agglomerate, and uniform in particle size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

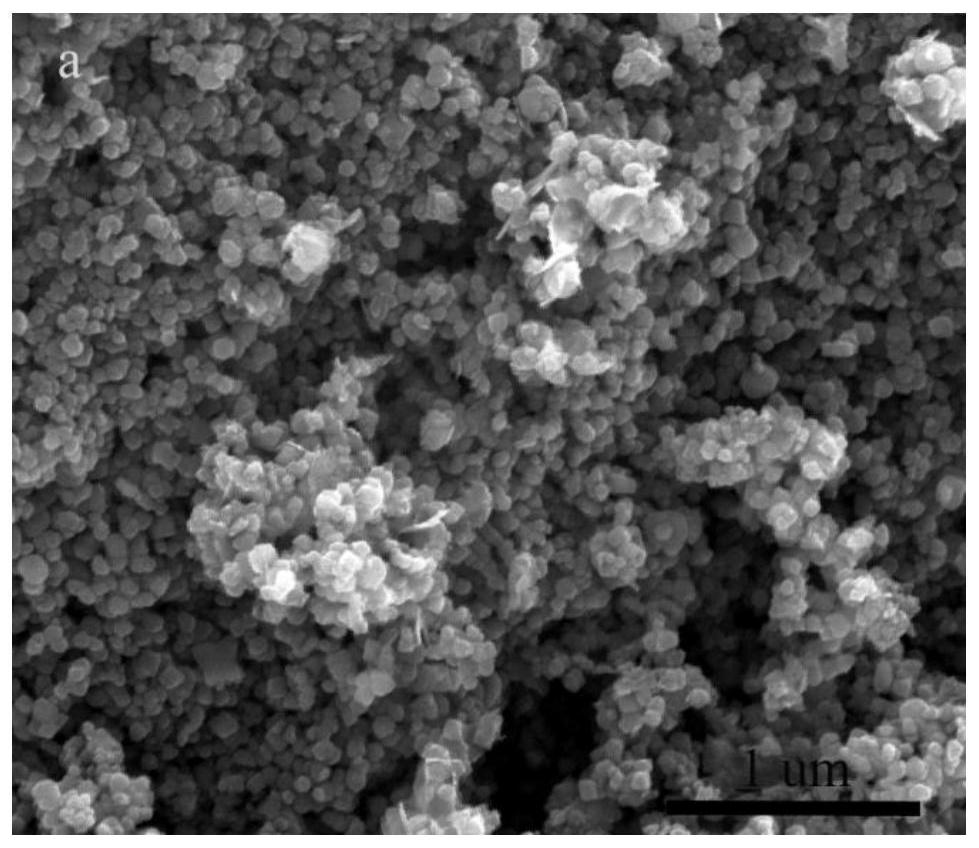

[0033] FeSO 4 ·7H 2 O (0.40g) and FeCl 3 (0.09g) was dissolved in 5 ml of deionized water, the air was evacuated using a vacuum pump, and filled with argon; then stirred at room temperature for 10 min, and then slowly added dropwise excess NaOH (0.2 mol / L); when the solution turns into black particles, stop adding NaOH, and then stir for 30 min. The resulting Fe 3 o 4 The nanoparticles were washed 3 times with water and dried at 80°C for 6 h to obtain the magnetic nanoparticles Fe 3 o 4 .

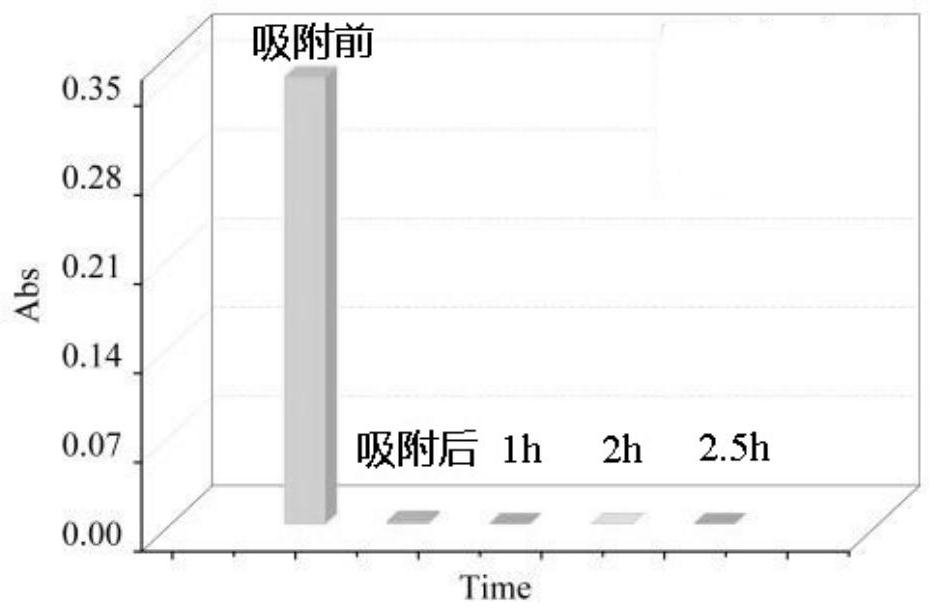

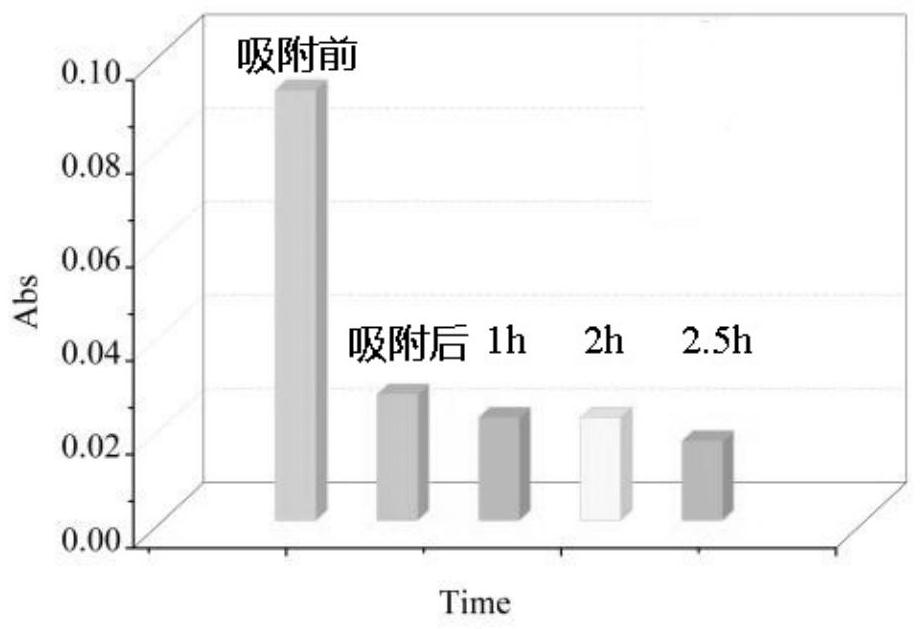

[0034] The magnetic nanoparticle Fe that this embodiment makes 3 o 4在 Under the irradiation of visible light (the light source is a Newport 3A solar simulator), the rhodamine B aqueous solution and the strongly adsorbed Congo red and methyl blue aqueous solutions are efficiently degraded. 15 mg catalyst can degrade 10 ml of rhodamine B aqueous solution (10mg / L) under visible light irradiation for 2.5 h, and the degradation result is better; Congo red (10mg / L) and methylene blue (1...

Embodiment 2

[0036] FeSO 4 ·7H 2 O (0.60g) and FeCl 3 (0.06g) was dissolved in 10 ml deionized water, the air was evacuated using a vacuum pump, and filled with nitrogen; then stirred at room temperature for 10 min, and then slowly added dropwise excess NaOH (0.4mol / L). When all the solutions turn into black particles, stop adding NaOH, and then stir for 60 minutes; the Fe obtained at last 3 o 4 The nanoparticles were washed 4 times with water and dried at 80°C for 5 h to obtain the magnetic nanoparticles Fe 3 o 4 .

Embodiment 3

[0038] FeSO 4 ·7H 2 O (0.50g) and FeCl 3 (0.08g) was dissolved in 8 ml of deionized water, the air was evacuated using a vacuum pump, and filled with argon; then stirred at room temperature for 10 min, and then slowly added dropwise excess NaOH (0.3 mol / L). When all the solutions turned into black particles, the addition of NaOH was stopped, followed by stirring for 50 min. The resulting Fe 3 o 4 Nanoparticles were washed 3 times with water, and dried at 95°C for 5.5h to obtain magnetic nanoparticles Fe 3 o 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com