Method for purifying punicalagin on basis of isomerization characteristics

A technology of punicalagin and purification methods, which is applied in chemical instruments and methods, esterified saccharides, organic chemistry, etc., can solve problems such as unreachable, low high-purity samples, and difficult purification, and achieve strong innovation and preparation A large amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] a. Take a pilot-scale reversed phase chromatographic column, the specification column length is 250mm×the inner diameter is 80mm, the particle size of the filler is 10μm, the mobile phase is methanol and 0.1% formic acid water with a volume ratio of 12:88, the flow rate is controlled at 180mL / min, the temperature is room temperature, and ultraviolet The detection wavelengths are 254nm and 366nm, equilibrate for 15min, ready for use;

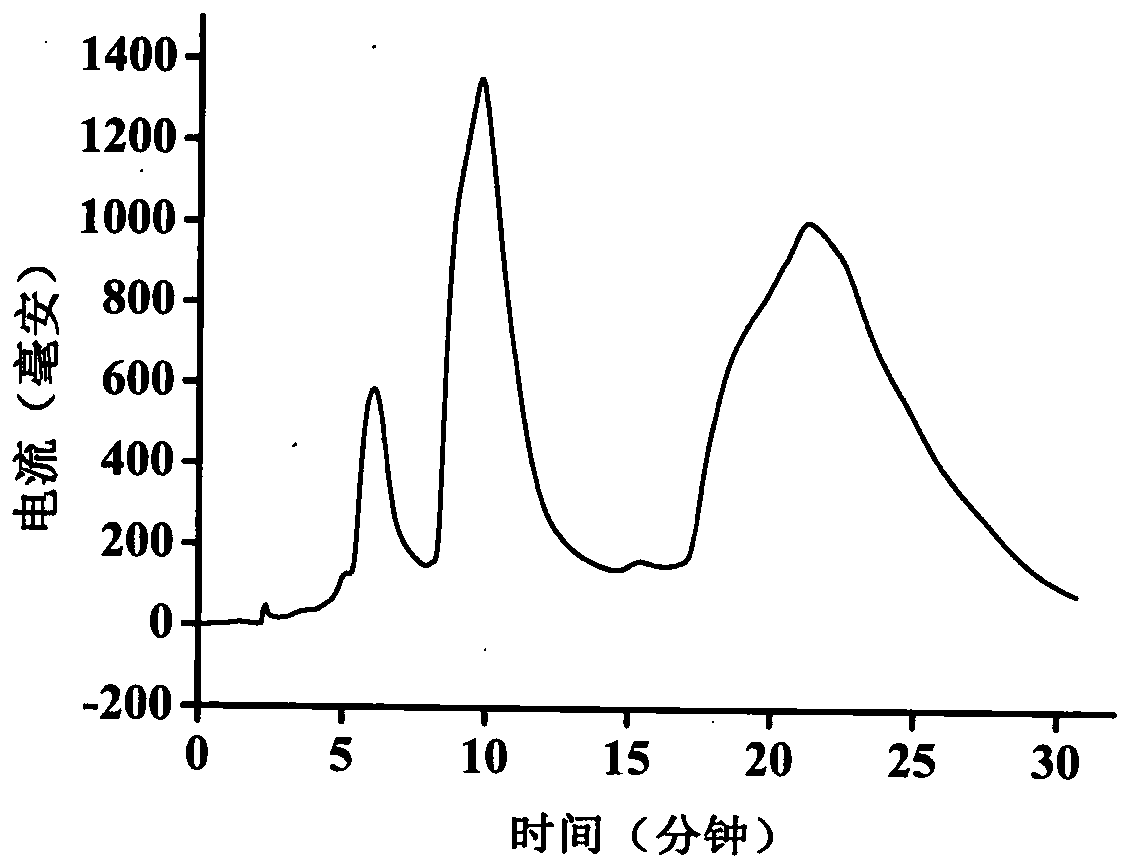

[0022] b. Weigh 6g of pomegranate peel extract, in which the content of punicalagin is about 32%, dissolve in 20mL of water, centrifuge, centrifuge at 10,000 rpm for 5 minutes, take the supernatant, and inject it through a six-way valve. In the equilibrated pilot-scale reversed-phase column figure 1 As shown, the component α-puunigalin component 1 with a time range of 10 min to 15 min is collected in a component tank, and concentrated to 20 mL with a rotary evaporator at a temperature of 50°C;

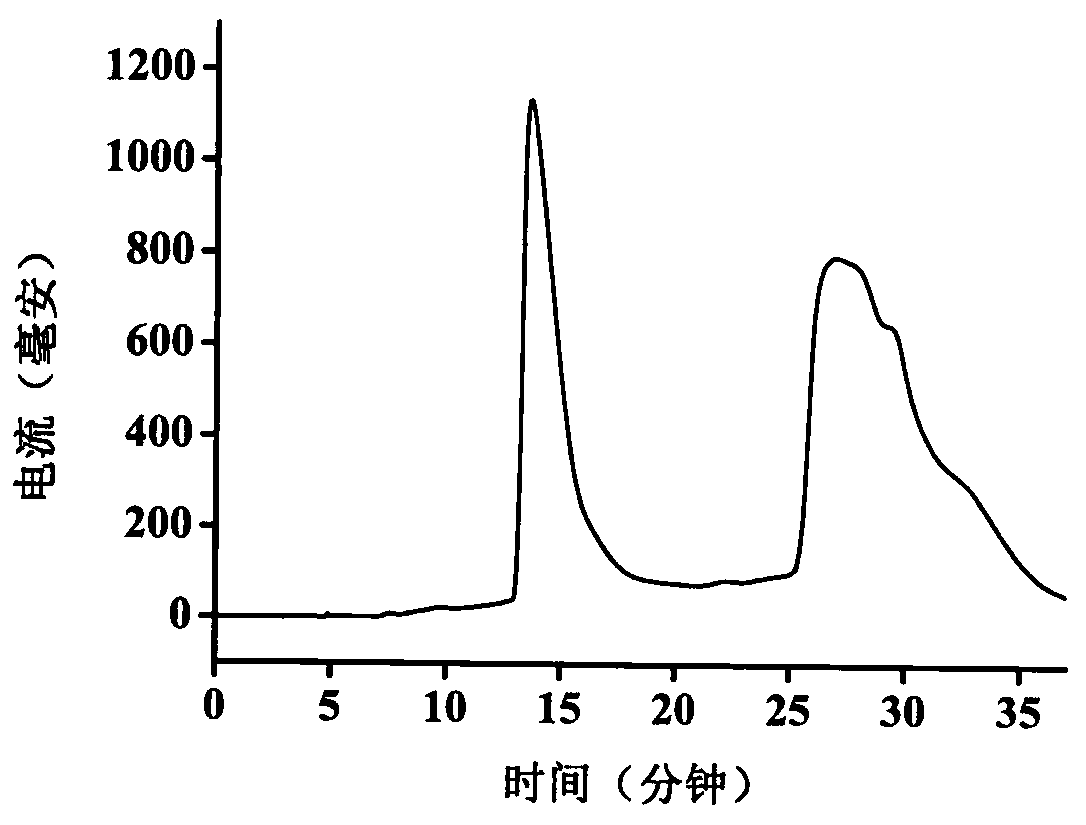

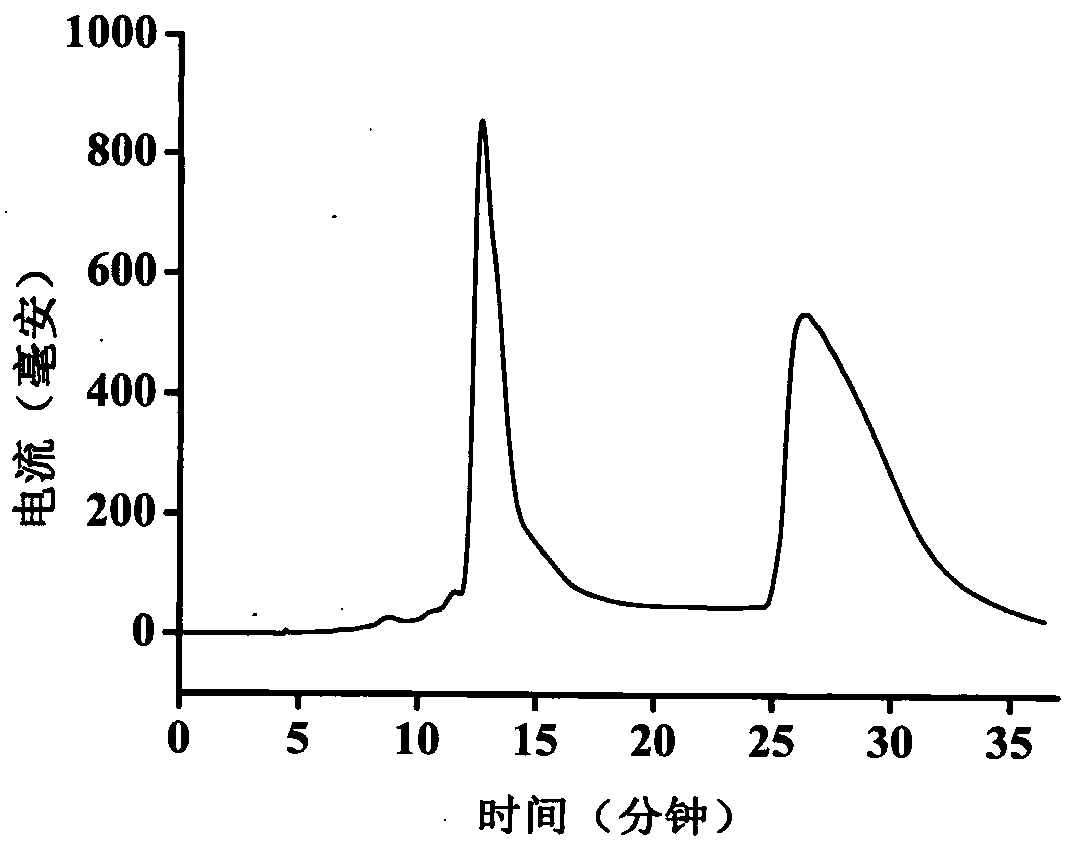

[0023] c. Re-inject the α-puunicalagin component ...

Embodiment 2

[0025] a. Take a pilot-scale reversed phase chromatographic column, the specification column length is 250mm×the inner diameter is 80mm, the particle size of the filler is 10μm, the mobile phase is methanol and 0.1% formic acid water with a volume ratio of 12:88, the flow rate is controlled at 180mL / min, the temperature is room temperature, and ultraviolet The detection wavelengths are 254nm and 366nm, equilibrate for 15min, ready for use;

[0026] b. Weigh 6g of pomegranate peel extract, in which the content of punicalagin is about 32%, dissolve in 20mL of water, centrifuge, centrifuge at 10,000 rpm for 5 minutes, take the supernatant, and inject it through a six-way valve. In the equilibrated pilot-scale reversed-phase column figure 1 As shown, the component β-puunicalagin component 4 with a time range of 17 min to 30 min is collected in a component tank, and concentrated to 20 mL with a rotary evaporator at a temperature of 50°C;

[0027] c. Re-inject β-puunicalagin component 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com