Low-molecular-weight polymer with functionally modified ends and preparation method thereof

A low-molecular-weight, polymer-based technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of high polymer solution injection pressure, increased dissolution time, economic cost, and small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

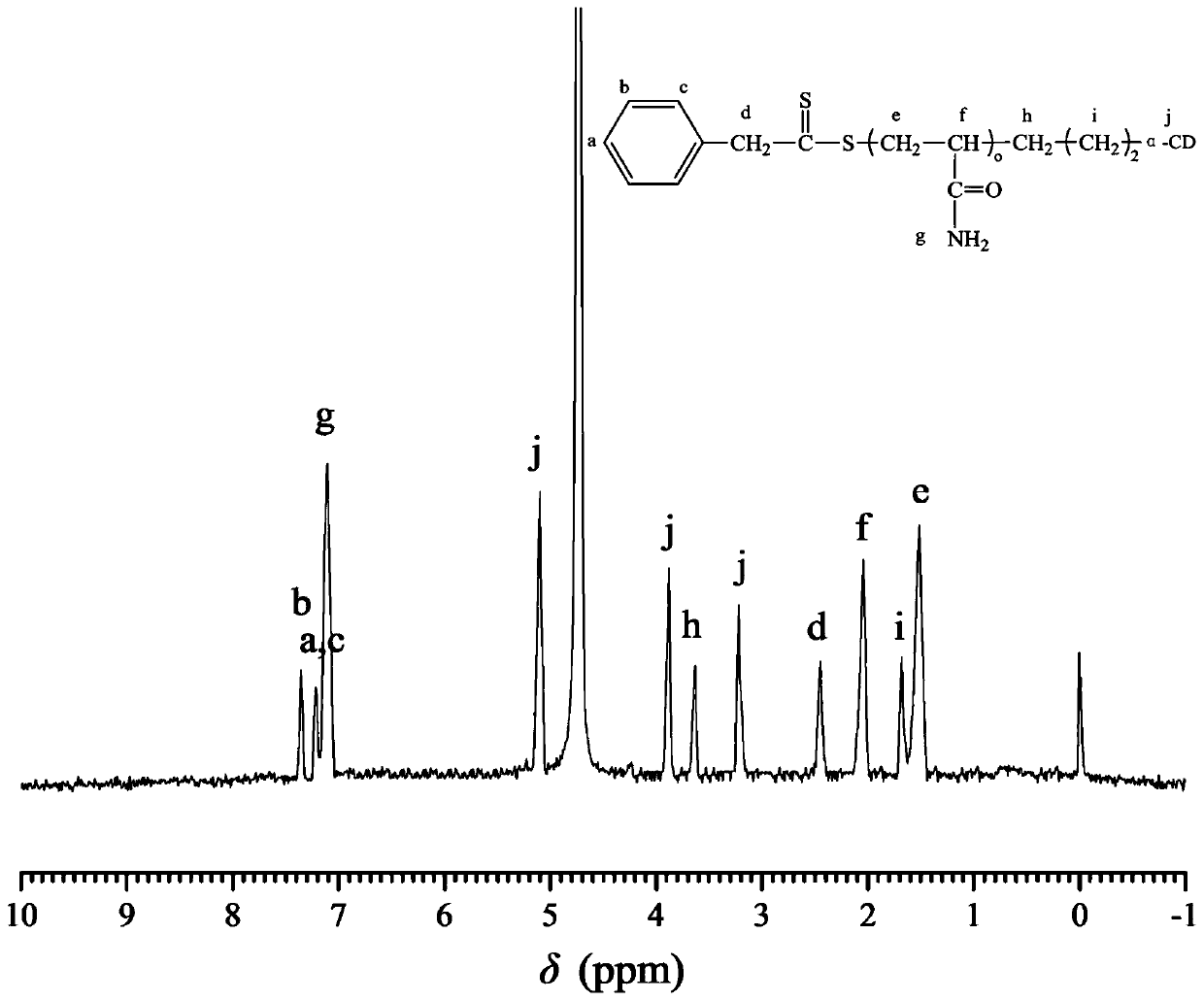

[0060] Accurately weigh a certain amount of acrylamide monomer and RAFT chain transfer agent and dissolve in a certain amount of deionized water, the mass concentration of acrylamide monomer is 25%, the mass concentration of RAFT chain transfer agent is 0.05%, and then placed in 250mL In a three-necked flask, stir continuously to dissolve it. The three-neck flask was placed in a constant temperature water bath, and N 2 And stirred for 0.5 hours until the solution was clear. The initiator is azobisisobutyronitrile (AIBN) injected with a syringe, and the amount of the initiator is 0.05% of the total mass of the monomers. The temperature was raised to 40°C, and the N 2 Stir continuously, seal the three-necked flask and place it for 6 hours, and finally get a transparent gel-like product, take it out and cut it into small pieces, purify it with ethanol precipitation three times, vacuum-dry and granulate the low-molecular-weight polymer product, and the calculated yield is about ...

Embodiment 2

[0062] Accurately take a certain amount of 2-acrylamide-2-methylpropanesulfonic acid (AMPS) and RAFT chain transfer agent and dissolve it in a certain amount of deionized water, the mass concentration of monomer is 30%, the mass of RAFT chain transfer agent The concentration is 0.1%, and then placed in a 250mL three-neck flask, stirring constantly to dissolve it. The three-neck flask was placed in a constant temperature water bath, and N 2 And stirred for 0.5 hours until the solution was clear. The initiator is azobisisobutyronitrile (AIBN) injected with a syringe, and the amount of the initiator is 0.1% of the total mass of the monomers. The temperature was raised to 45°C, and the N 2 Stir continuously, place the three-neck flask sealed for 6 hours, and finally obtain a transparent gel-like product, which is taken out and cut into small pieces, purified by ethanol precipitation three times, vacuum-dried, and granulated low-molecular-weight polymer product. A polymer repres...

Embodiment 3

[0064] Accurately weigh a certain amount of betaine type monomer (formula II), acrylamide, quaternary ammonium salt type long carbon chain association monomer (formula III, n 2 11,) and RAFT chain transfer agent are dissolved in a certain amount of deionized water, the mass concentration of the monomer is 20%, and the mass concentration of RAFT chain transfer agent is 0.15%, then placed in a 250mL three-necked flask, constantly stirred to make it dissolve. The three-neck flask was placed in a constant temperature water bath, and N 2 And stirred for 0.5 hours until the solution was clear. The initiator is azobisisobutyronitrile (AIBN) injected with a syringe, and the amount of the initiator is 0.05% of the total mass of the monomers. The temperature was raised to 35°C, and the N 2 Stir continuously, place the three-neck flask sealed for 5.5 hours, and finally obtain a transparent gel-like product, which is taken out and cut into small pieces, purified by ethanol precipitatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com