Ionic rubber elastic body and preparation method thereof, ionized electronic skin

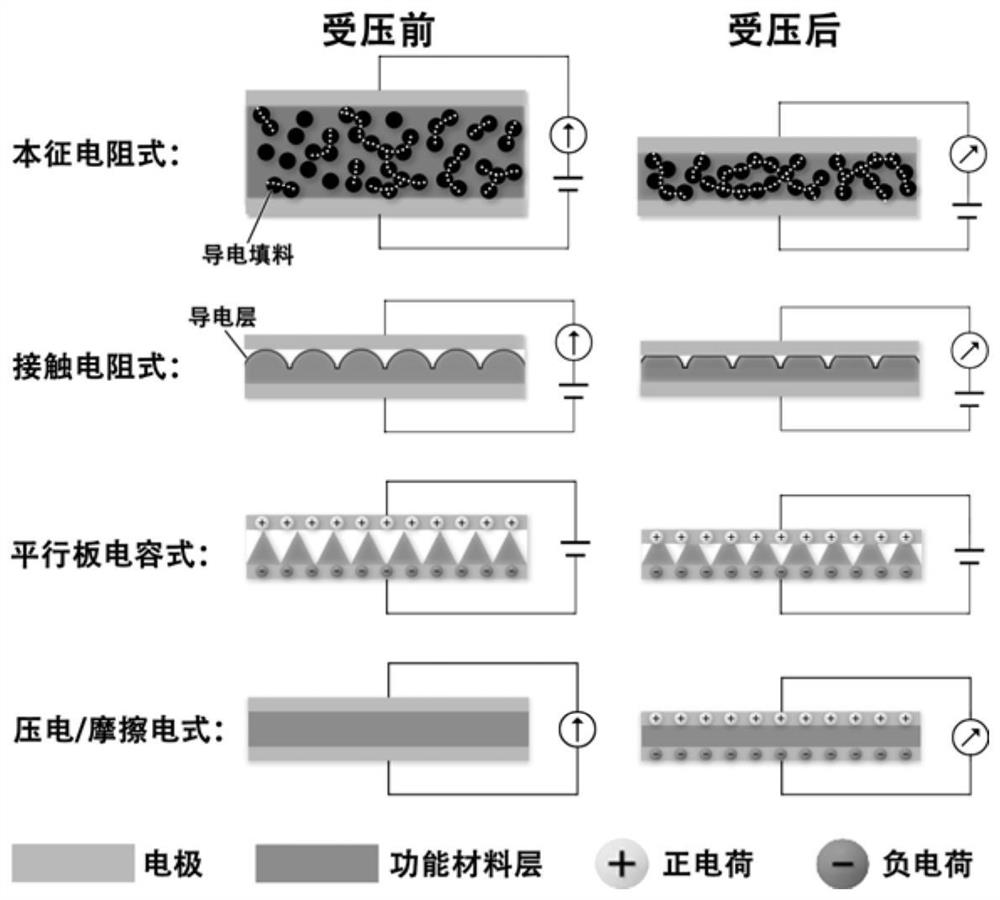

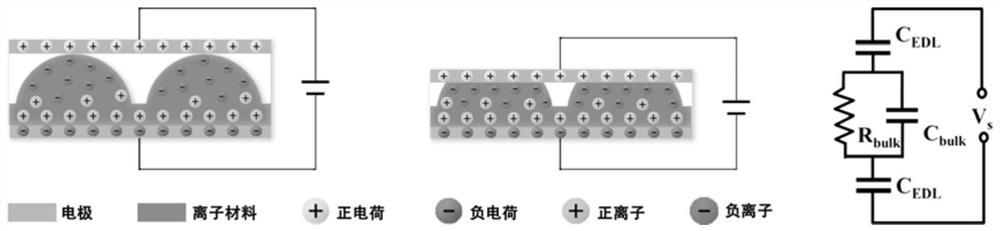

A technology of ionic rubber and electronic skin, which is applied in the field of sensors, can solve the problems of low sensitivity, poor mechanical structure compatibility, and complex structure of electronic skin, and achieve the effects of strong anti-interference ability, improved compatibility, and good response linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The second aspect of the embodiments of the present invention provides a method for preparing an ionic rubber elastomer, comprising the following steps:

[0044] S01. take each component according to the formula of ionic rubber elastic body of the present invention;

[0045] S02. Mixing the rubber material precursor and its curing agent, liquid ionic material, solid nanomaterial, and additives to obtain a slurry-like precursor material;

[0046] S03. Depositing the precursor material on the substrate and curing it to obtain an ionic rubber elastic body.

[0047] The preparation method of the ionic rubber elastomer provided by the embodiment of the present invention only needs to provide the rubber material precursor and its curing agent, liquid ionic material, solid nanomaterial and additive according to the formula of the ionic rubber elastomer, and mix the raw materials and process them in the It can be obtained by curing on the substrate, and the operation method is...

Embodiment 1

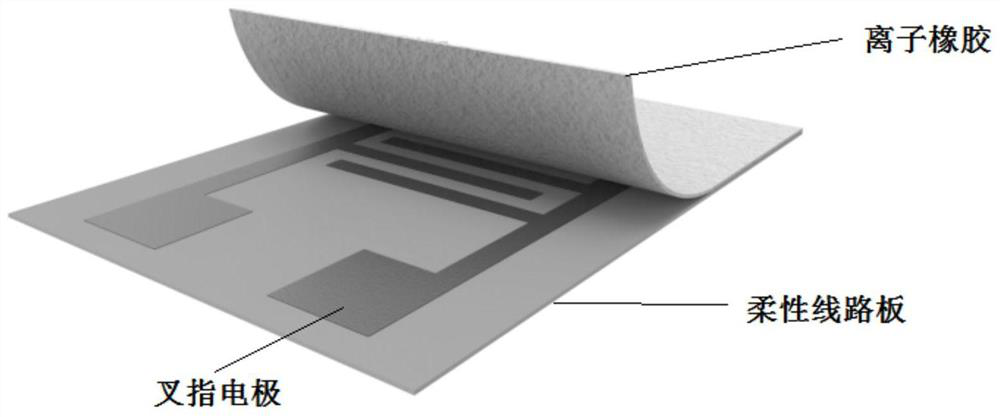

[0059] A method for preparing an ionotronic electronic skin, comprising the following steps:

[0060] Preparation of ionic rubber elastomer: add Sylgard 184PDMS silicone elastomer precursor and curing agent in a mass ratio of 10:1, and add lithium bistrifluoromethanesulfonylimide with a mass ratio of 1:1 to the silicone elastomer precursor Dioctyl phthalate solution, in which lithium bistrifluoromethanesulfonimide is dissolved in dioctyl phthalate in advance to form a solution with a mass fraction of 5%, adding a specific surface area of 300m 2 The fumed nano-silica of / g, its quality accounts for 10% of organosilicon elastomer precursor, adds and occupies the leveling agent of organosilicon elastomer precursor 0.1%, the defoamer of 0.3%, uses mechanical stirring at 500 revs Stirring at 1 / min for 1 hour to pre-mix all the components, and then use a centrifugal mixer to stir at 5000 rpm for 5 minutes to fully mix the components to obtain ionic rubber precursor slurry. Lay 10...

Embodiment 2

[0065] A method for preparing an ionotronic electronic skin, comprising the following steps:

[0066] Preparation of ionic rubber elastomer: add 1-butyl-1-methylpyrrolidine bis(trifluoromethanesulfonyl)imide in powdered nitrile rubber, and nitrile rubber and 1-butyl-1-methylpyrrole The mass ratio of alkane bis(trifluoromethanesulfonyl)imide is 2:1; Add particle diameter and be the active nano-calcium carbonate of 50nm, its quality accounts for 20% of powder nitrile rubber, adds and accounts for powder nitrile rubber 0.1% Leveling agent, 0.3% defoaming agent, use mechanical stirring at 60 rpm, 150 ° C for 1 hour to pre-mix all components, and then add 1.5% peroxide by weight of powdered nitrile rubber Dicumyl is used as a vulcanizing agent, and a three-roll machine is used to mix all materials evenly. Use a 500-mesh sandblasted stainless steel plate as a template, and use a flat vulcanizer to vulcanize at 180°C for 4 hours. After the vulcanization is completed, the nitrile rub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com