Microporous skin-core structured bi-component composite fiber preparation method

A skin-core structure and composite fiber technology, applied in the field of spinning, can solve the problems of reduced efficacy, inability to exert the actual efficacy of functional masterbatch, and the concentration of oil agent should not be too high, to achieve strong deodorizing and sterilizing functions, improve hydrophilicity, Effect of improving skin affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

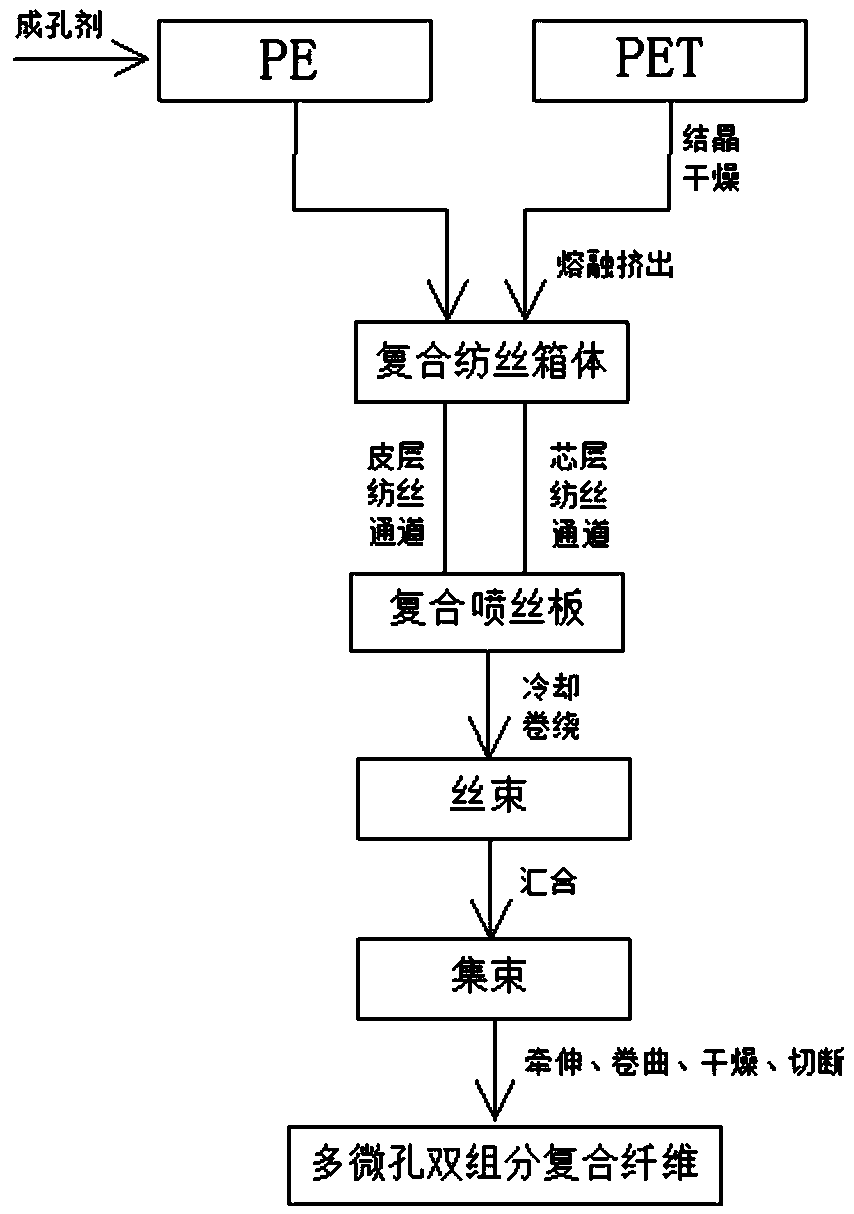

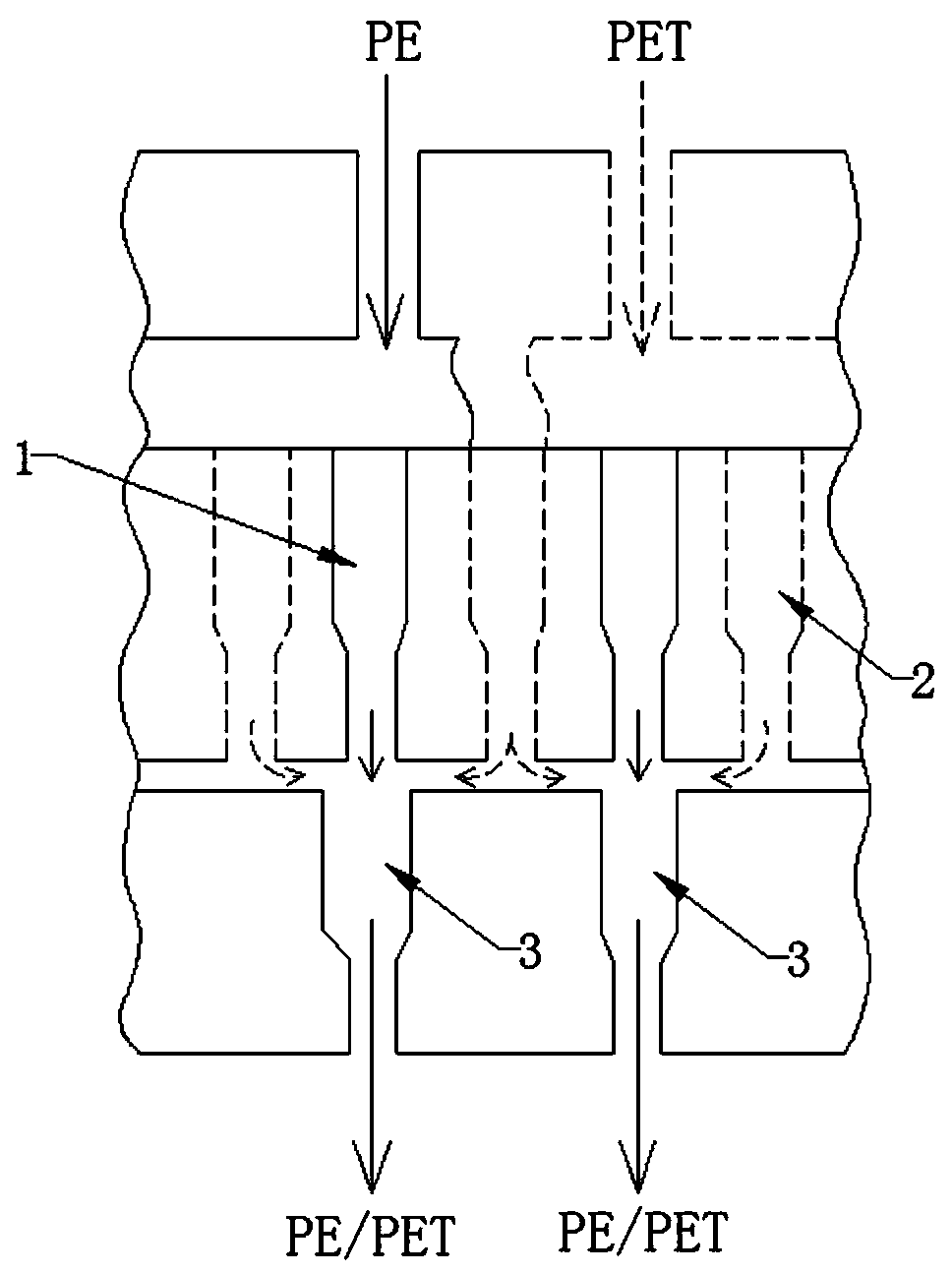

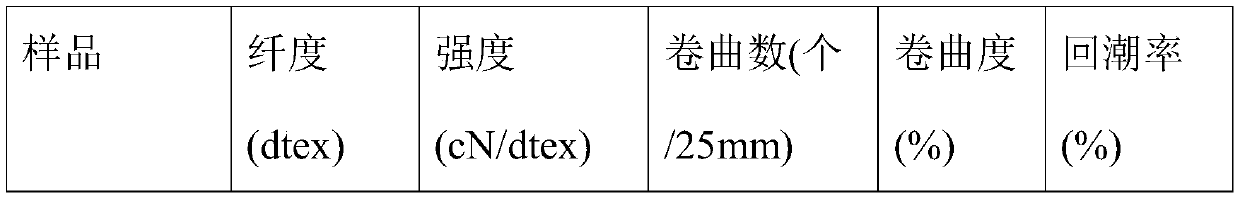

[0031] A method for preparing a microporous sheath-core structure bicomponent composite fiber, specifically comprising the following steps:

[0032] S1. Take polyethylene and polyethylene terephthalate with a mass ratio of 30:70, and carry out crystallization and drying of polyethylene terephthalate. The crystallization drying temperature is 150° C., and the drying time is 60 minutes. Add a pore-forming agent to the polyethylene and mix evenly to assist in the formation of micropores during the skin spinning process. The pore-forming agent is sodium bicarbonate that can be completely decomposed at 270 ° C. The amount added is 10% of the polyethylene mass. Ethylene glycol phthalate and polyethylene with pore forming agent are passed through melting screw extrusion equipment to obtain polyethylene spinning melt and polyethylene terephthalate spinning melt, and then sent to the composite spinning box , respectively pass polyethylene terephthalate and polyethylene with pore-formin...

Embodiment 2

[0040] A method for preparing a microporous sheath-core structure bicomponent composite fiber, specifically comprising the following steps:

[0041] S1, take the polyethylene and polyethylene terephthalate that mass ratio is 70:40, carry out crystallization and drying to polyethylene terephthalate, the crystallization drying temperature of polyethylene terephthalate The temperature is 160℃, the drying time is 60min, and the pore-forming agent is added to polyethylene and mixed evenly to assist in the formation of micropores during the skin spinning process. The pore-forming agent is water-soluble polyvinylpyrrolidone, and the amount added is 1% of the polyethylene mass %, polyethylene terephthalate and polyethylene with pore-forming agent are passed through melting screw extrusion equipment to obtain polyethylene spinning melt and polyethylene terephthalate spinning melt and then sent into the composite spinning box;

[0042] S2. The polyethylene spinning melt and the polyeth...

Embodiment 3

[0050] A method for preparing a microporous sheath-core structure bicomponent composite fiber, specifically comprising the following steps:

[0051] S1, take the polyethylene and polyethylene terephthalate that mass ratio is 60:50, carry out crystallization and drying to polyethylene terephthalate, the crystallization drying temperature of polyethylene terephthalate The temperature is 155°C, and the drying time is 50min. Add a pore-forming agent to polyethylene and mix evenly to assist in the formation of micropores during the skin spinning process. The pore-forming agent is ethylene glycol with a boiling point of 197°C, and its addition amount is polyethylene 6% of the mass, the polyethylene terephthalate and the polyethylene added with the pore forming agent are passed through the melting screw extrusion equipment to obtain the polyethylene spinning melt and the polyethylene terephthalate spinning melt. After the body is sent to the composite spinning box;

[0052] S2. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| Curvature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com