Ansys-based copper alloy flat plate butt-welding hot crack prediction method

A technology of plate docking and prediction method, which is applied in the direction of instruments, calculations, electrical digital data processing, etc., to achieve the effect of reducing welding process tests, saving manpower and material resources, and reducing the occurrence of thermal cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

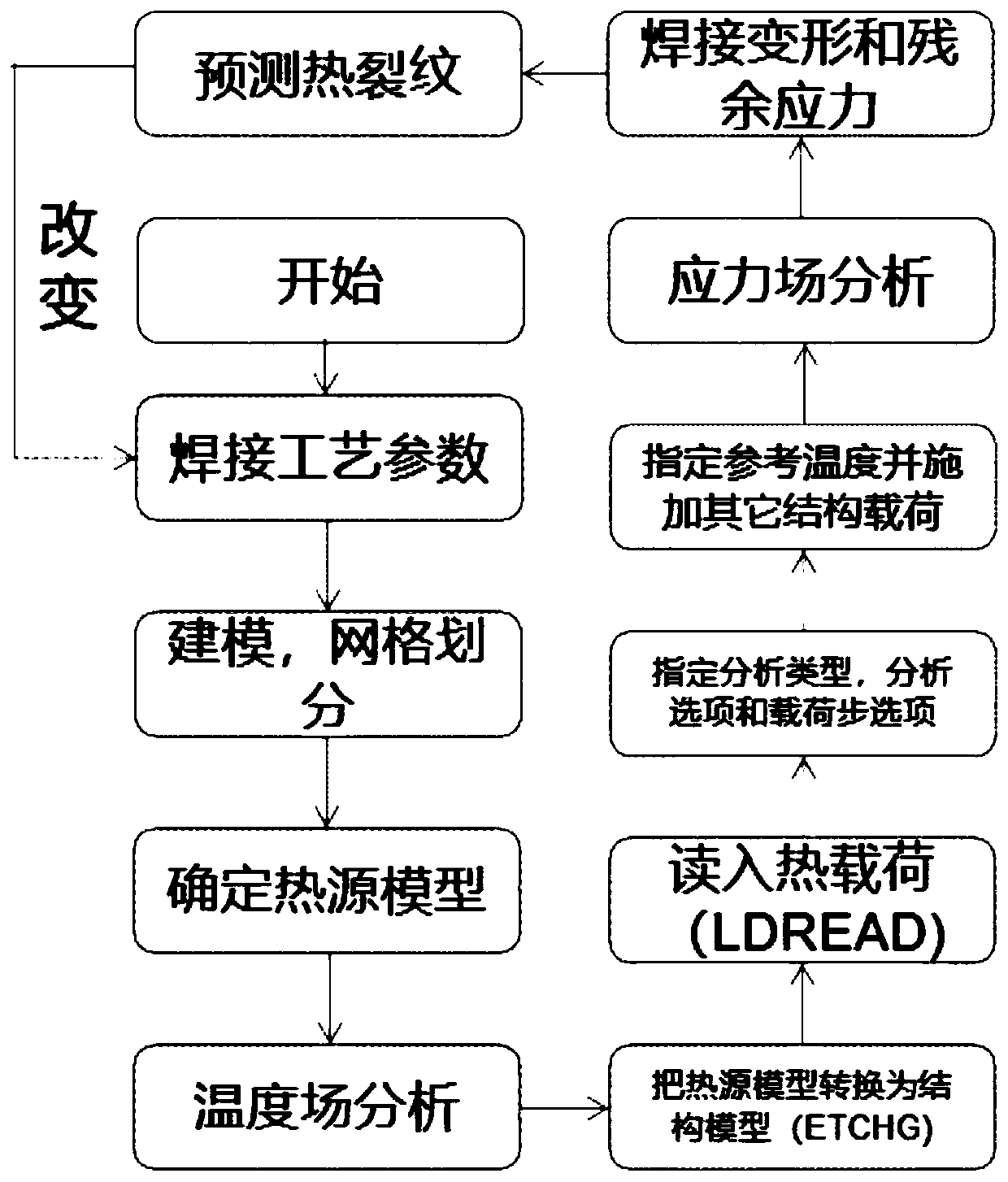

[0044] Embodiment 1: An ansys-based method for predicting thermal cracks in copper alloy flat plate butt welding, including: S1: determine the parameters of the welding process; S2: determine the properties of the welding material: determine the thermal analysis physical parameters and stress analysis parameters of the copper alloy casting : temperature range, density, thermal conductivity, specific heat capacity, enthalpy, total heat transfer coefficient for radiation and convection, elastic modulus, yield strength and shear modulus, linear expansion coefficient, Poisson's ratio; S3: Create finite elements in ANSYS Model, select the thermal analysis unit, and divide the grid by sweeping according to the size of the finite element model; S4: Select the heat source model: select the heat source model according to the welding process conditions; S5: Calculate the temperature field: simulate through the birth and death unit For the movement of the heat source, the heat source calc...

Embodiment 2

[0047] Embodiment 2: A method for predicting thermal cracks in butt welding of copper alloy flat plates based on ansys, including:

[0048] S1: Determine the parameters of the welding process;

[0049] S2: Determine the properties of the welding material: determine the thermal analysis physical parameters and stress analysis parameters of copper alloy castings: temperature range (°C), density (kg / m3), thermal conductivity (W / (m*K)) (considering the molten pool convection), specific heat capacity (J / kg / K), enthalpy (J / M3), total heat transfer coefficient for radiation and convection (W / m^2*K), modulus of elasticity (pa), yield strength and shear modulus volume, coefficient of linear expansion, Poisson's ratio;

[0050] S3: Create a finite element model in ansys, select a thermal analysis unit, and divide the grid by sweeping according to the size of the finite element model; the analysis unit uses solid70.

[0051] S4: Select the heat source model: select the heat source mode...

Embodiment 3

[0069] Embodiment 3: On the basis of Embodiment 2, this embodiment can be replaced by, specifically

[0070] In summary, a method for predicting thermal cracks in copper alloy flat-plate butt welding based on ansys of the present invention determines optimal welding process parameters and reduces thermal cracks by analyzing the ratio of copper alloy flat-plate butt welding welding process parameters through a numerical simulation model The numerical simulation model reduces the number of welding process tests and saves manpower and material resources to the greatest extent; it can predict the distribution of residual stress, so as to provide a post-weld heat treatment plan in time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com