Boehmite-containing ceramic coating lithium battery structure

A ceramic coating, lithium battery technology, used in secondary batteries, structural parts, battery pack components, etc., can solve problems such as troublesome operation, battery fire, explosion, etc., to prevent heat diffusion, control thermal runaway, energy high density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

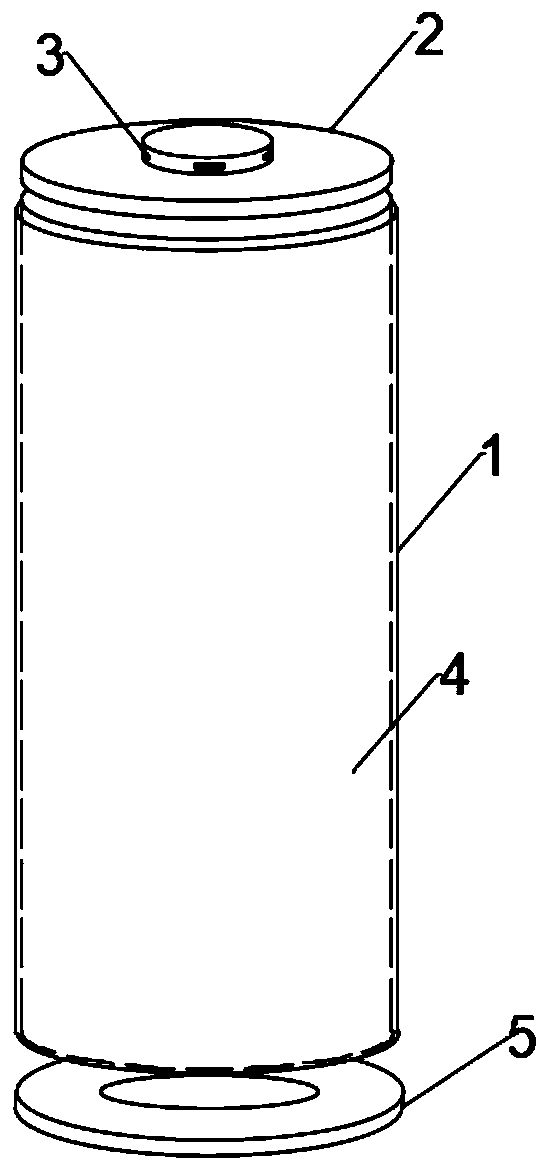

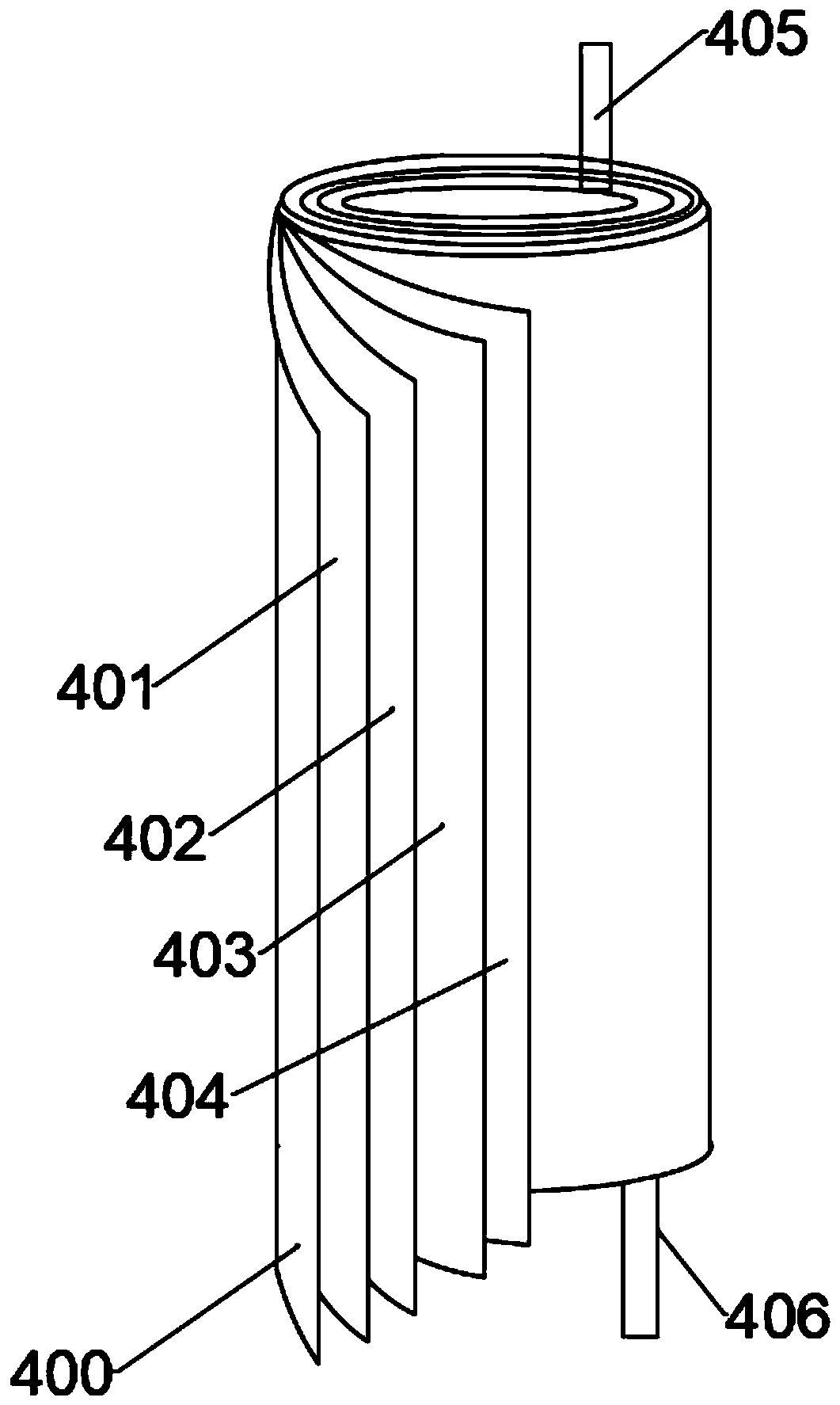

[0035] Such as Figure 1-6 As shown, a boehmite-containing ceramic coating lithium battery structure includes a battery main body 4, and the battery main body 4 includes a diaphragm one 404, a positive electrode sheet 403, a diaphragm two 402, Negative electrode sheet 401 and separator three 400, negative electrode sheet 401 is provided with current collector 4012, is welded with negative electrode ear 406 on collector body 4012, is provided with positive electrode ear 405 on described positive electrode sheet 403, described positive electrode sheet 403 and / or negative electrode sheet 401 is coated with polymer coating 407;

[0036] The upper surface of the battery body is equipped with a positive cap 2, and the side surface of the positive cap 2 is uniformly provided with through holes 3;

[0037] The outer surface of the battery main body 4 is provided with a casing 1, the casing 1 is cylindrical, the casing 1 is filled with electrolyte, the battery main body 4 is immersed ...

Embodiment 2

[0040] This embodiment is a further optimization made on the basis of Example 1, specifically the preparation method of the polymer coating is as follows:

[0041] S1: Add ceramic mixed powder, dispersant, and water into a ball mill, mill for 0.5 hours, then add binder, and continue milling for 20 minutes to prepare a slurry;

[0042] S2: Coat the slurry obtained after dispersion on both sides of the positive electrode sheet 403 and the negative electrode sheet 401 of the lithium battery, and the thickness of the coating layer is 1 μm;

[0043] S3: Drying: Put the positive electrode sheet 403 and the negative electrode sheet 401 coated in step S3 into a vacuum drying oven for drying at a drying temperature of 60°C.

[0044] The dispersant is acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer.

[0045] The binder described in this embodiment adopts polyvinyl alcohol.

[0046] The quality of the dispersant is 0.5% of the mass of the ceramic mixed powder, the qual...

Embodiment 3

[0050] This embodiment is a further optimization made on the basis of Example 1, specifically the preparation method of the polymer coating is as follows:

[0051] S1: Add ceramic mixed powder, dispersant, and water into a ball mill, mill for 1.5 hours, then add binder, and continue milling for 30 minutes to prepare a slurry;

[0052] S2: Coat the slurry obtained after dispersion on both sides of the positive electrode sheet 403 and the negative electrode sheet 401 of the lithium battery, and the thickness of the coating layer is 2 μm;

[0053] S3: Drying: Put the positive electrode sheet 403 and the negative electrode sheet 401 coated in step S3 into a vacuum drying oven for drying at a drying temperature of 70°C.

[0054] The dispersant sodium polyacrylate.

[0055] The binder described in this embodiment adopts polyvinyl alcohol.

[0056] The quality of the dispersant is 2% of the mass of the ceramic mixed powder, the quality of the binder is 6% of the mass of the ceramic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com