Preparation method of pyridine-functionalized chitosan adsorbent

A technology for converting chitosan and adsorbent, which is applied in the field of preparation of pyridine functionalized chitosan adsorbent, can solve the problems of heavy metal or antibiotic limitation, inability to remove heavy metal and antibiotic simultaneously, low adsorption capacity, etc., and achieves low material cost. , the effect of improving adsorption capacity and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

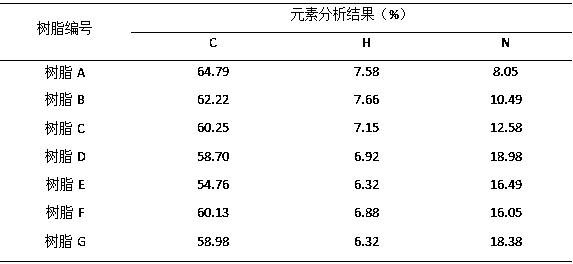

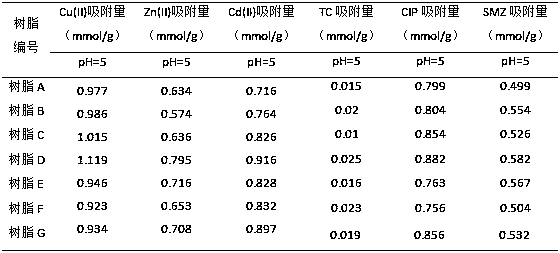

Embodiment 1

[0018] A kind of preparation method of pyridine functionalized chitosan adsorbent proposed by the present embodiment comprises the following steps:

[0019] S1: 0.1 g of polyethyleneimine with a mass concentration of 5-100 g / L, 0.05 g of 2-chloromethylpyridine hydrochloride with a mass concentration of 2.5-100 g / L and 0.2 g of a mass concentration of 10-100 g / L Dissolve g / L sodium carbonate in an aqueous solution of 1 ml ethanol and 5 ml distilled water, set the dissolving temperature to 85 °C, and set the dissolving time to 2 h, and at the same time use magnetic force in an 85 °C oil bath to stir until it is evenly stirred, then Use the cooling device for cooling operation. The cooling device first cools at a rate of 3-5°C / min until it cools down to 30°C. The cooling device then cools at a rate of 0.3-0.5°C / min until it cools to room temperature, and then Use a centrifugal device and a filter sieve to perform centrifugation and filtration in sequence, and finally spin-dry in ...

Embodiment 2

[0025] A kind of preparation method of pyridine functionalized chitosan adsorbent proposed by the present embodiment comprises the following steps:

[0026]S1: 0.2g of polyethyleneimine with a mass concentration of 5-100 g / L, 0.05g of 2-chloromethylpyridine hydrochloride with a mass concentration of 2.5-100 g / L and 0.2g of a mass concentration of 10-100 Dissolve g / L sodium carbonate in an aqueous solution of 1 ml ethanol and 5 ml distilled water, set the dissolving temperature to 85 °C, and set the dissolving time to 2 h, and at the same time use magnetic force in an 85 °C oil bath to stir until it is evenly stirred, then Use the cooling device for cooling operation. The cooling device first cools at a rate of 3-5°C / min until it cools down to 30°C. The cooling device then cools at a rate of 0.3-0.5°C / min until it cools to room temperature, and then Use a centrifugal device and a filter sieve to perform centrifugation and filtration in sequence, and finally spin-dry in a rotary...

Embodiment 3

[0032] A kind of preparation method of pyridine functionalized chitosan adsorbent proposed by the present embodiment comprises the following steps:

[0033] S1: 0.7g of polyethyleneimine with a mass concentration of 5-100 g / L, 0.25g of 2-chloromethylpyridine hydrochloride with a mass concentration of 2.5-100 g / L and 0.3231g of a mass concentration of 10-100 g / L Dissolve g / L sodium carbonate in an aqueous solution of 15 ml ethanol and 5 ml distilled water, set the dissolving temperature to 85 °C, and set the dissolving time to 2 h, and at the same time use magnetic force in an 85 °C oil bath to stir until it is evenly stirred, then Use the cooling device for cooling operation. The cooling device first cools at a rate of 3-5°C / min until it cools down to 30°C. The cooling device then cools at a rate of 0.3-0.5°C / min until it cools to room temperature, and then Use a centrifugal device and a filter sieve to perform centrifugation and filtration in sequence, and finally spin-dry in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com