Method for preparing cationic unordered rock salt structure anode material through high-valent-state transition metal ion replacement combination strategies

A technology of transition metal ions and positive electrode materials, applied in structural parts, chemical instruments and methods, manganate/permanganate, etc., to achieve the effect of simple process, conducive to popularization and application, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

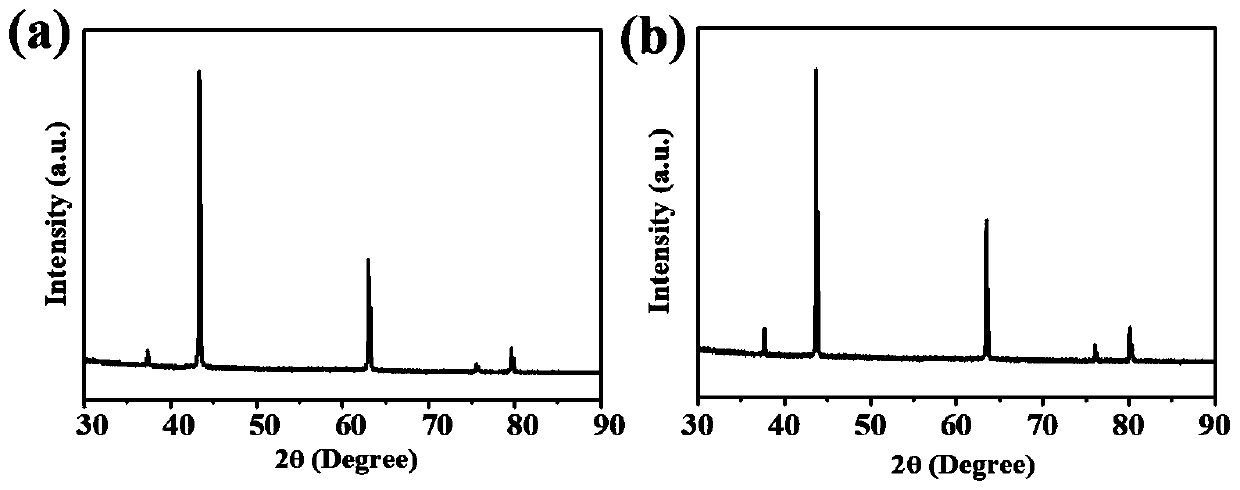

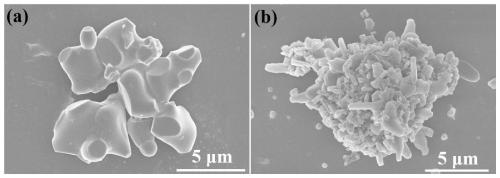

[0028] Example 1: Cationic disordered rock salt structure cathode material Li 1.2 Ti 0.59 mn 0.22 o 2 preparation of

[0029] LiOH and TiO 2 , MnO according to the molar ratio of Li: M: M': F = 1.26: 0.59: 0.22: 0. As for the ball mill tank, dry grinding at a speed of 1450r / min without any medium for 12 hours to obtain a uniformly mixed metal salt precursor body;

[0030] The metal salt precursor was placed in a tube furnace, heated to 900°C at a rate of 2°C / min in an Ar atmosphere, kept for 20 hours, and then naturally cooled to room temperature to obtain a cationic disordered rock salt structure Li 1.2 Ti 0.59 mn 0.22 o 2 Cathode material.

Embodiment 2

[0031] Example 2: Cationic disordered rock salt structure cathode material Li 1.2 Ti 0.37 mn 0.44 o 2 preparation of

[0032] LiOH and TiO 2 , Mn 2 o 3 According to the molar ratio of Li: M: M': F = 1.26: 0.37: 0.44: 0, put it in the ball mill tank, dry mill at a speed of 1450r / min without any medium for 12 hours, and obtain a uniformly mixed metal salt precursor;

[0033] The metal salt precursor was placed in a tube furnace, heated to 900°C at a rate of 2°C / min in an Ar atmosphere, kept for 20 hours, and then naturally cooled to room temperature to obtain a cationic disordered rock salt structure Li 1.2 Ti 0.37 mn 0.44 o 2 Cathode material.

Embodiment 3

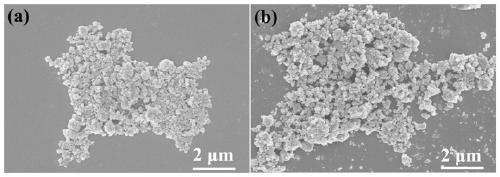

[0034] Example 3: Cationic disordered rock salt structure cathode material Li 1.2 Ti 0.55 mn 0.25 o 1.9 f 0.1 preparation of

[0035] LiOH and TiO 2, MnO, LiF according to the molar ratio of Li: M: M': F = 1.26: 0.55: 0.25: 0.1 in the ball mill tank, dry grinding at 1450r / min without any medium for 12 hours to obtain a uniformly mixed metal salt precursor;

[0036] Put the metal salt precursor in a tube furnace, raise the temperature to 950°C at a rate of 2°C / min in an Ar atmosphere, heat it for 15 hours, and then cool it down to room temperature naturally to obtain Li with a cationic disordered rock salt structure. 1.2 Ti 0.55 mn 0.25 o 1.9 f 0.1 Cathode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com