Method for gasification of fluidized bed gasified fly ash retaining to furnace

A technology of fluidized bed gasification and fly ash, which is applied in the direction of granular/powdered fuel gasification, chemical industry, and the manufacture of combustible gas, etc., which can solve the problems of increasing equipment investment and production costs, and achieve low investment costs for enterprises and high efficiency. The effect of gasification activity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

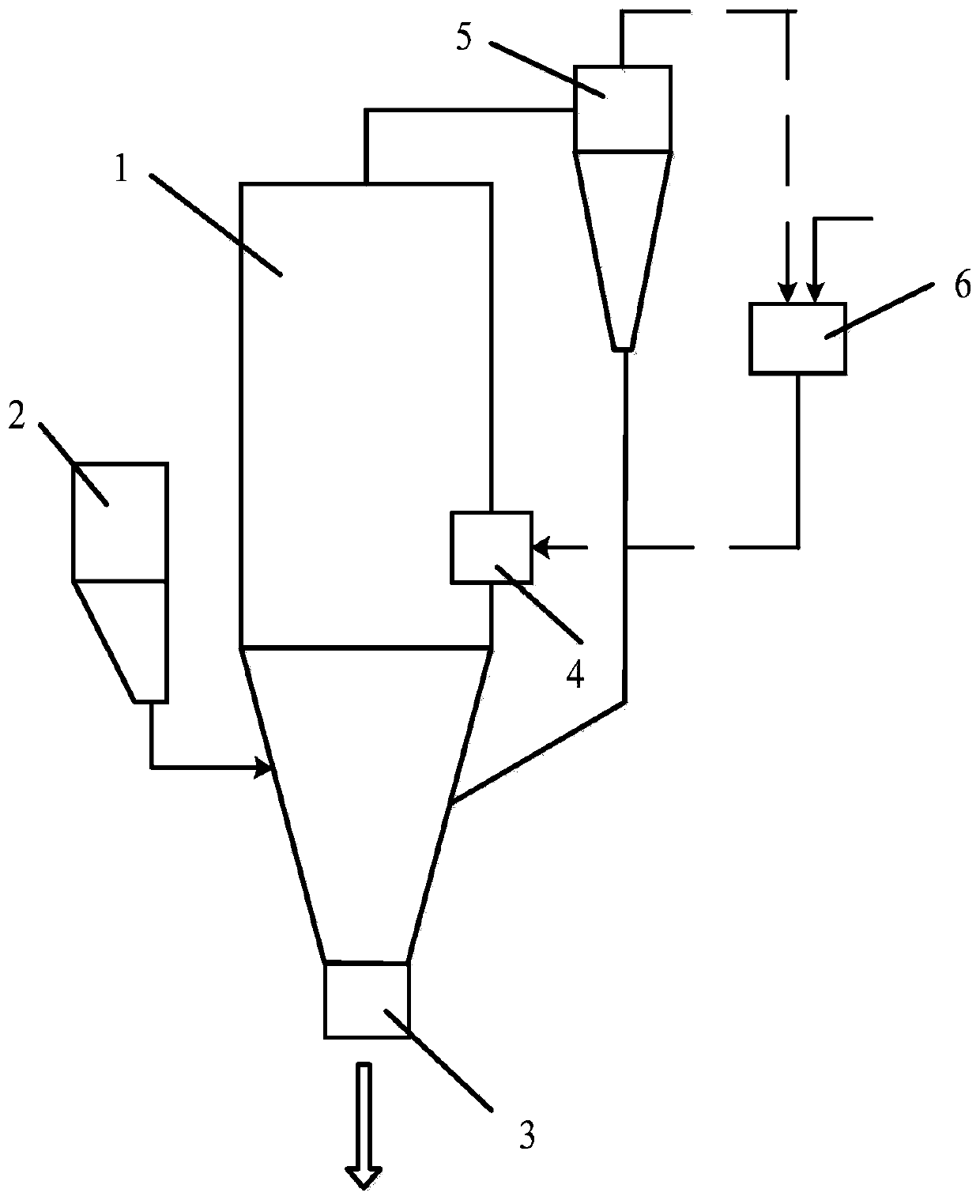

Image

Examples

Embodiment 1

[0015] Example 1: The fluidized bed gasification fly ash is sprayed into the dilute phase zone of the fluidized bed gasification furnace at a temperature of 800-1000° C. with air at a gas velocity of 3-6 m / s, and the gasification pressure is normal pressure. At the same time, the coal material is fed into the gasifier from the bottom of the fly ash injection inlet by the screw feeder, and then falls into the dense phase area, where it undergoes partial combustion and gasification reaction with the air input from the bottom of the gasifier. During the entire gasification process, the carbon conversion rate of raw materials can reach more than 80%.

Embodiment 2

[0016] Example 2: Calcium oxide with a mass fraction of 5% was added to the gasification fly ash as a catalyst and a desulfurizer, the feed oxygen-containing flow was air, and the gasification pressure was normal pressure. At the same time, the coal material is fed into the gasifier from the bottom of the fly ash injection inlet by the screw feeder, and then falls into the dense phase area, where it undergoes partial combustion and gasification reaction with the air input from the bottom of the gasifier. The carbon conversion rate of the raw material can reach more than 85%, and the H in the gas 2 The content of S is greatly reduced.

Embodiment 3

[0017] Example 3: The mixed raw material of fluidized bed gasification fly ash and calcium oxide with a mass fraction of 5% is sprayed into a fluidized bed gasification furnace with a temperature of 800-1000° C. with an oxygen-rich flow with an oxygen content of 30%. In the dilute phase zone, the gasification pressure is normal pressure. At the same time, the coal material is fed into the gasifier from the bottom of the fly ash inlet by the screw feeder, and then falls into the dense phase area, where it is partially burned and gasified with the air input from the bottom of the gasifier. The carbon conversion rate of the raw material can reach more than 90%, and at the same time, the calorific value of the gasification gas can be increased by more than 5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com