Preparation method of composite electrode material with foamed coating layer

A composite electrode and cladding layer technology, which is applied in the direction of positive electrode, battery electrode, active material electrode, etc., can solve the problems of poor cycle performance, poor conductivity of nickel-cobalt-manganese ternary materials, and unstable structure, so as to improve crystallinity , Electrode material structure is stable, the effect of improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

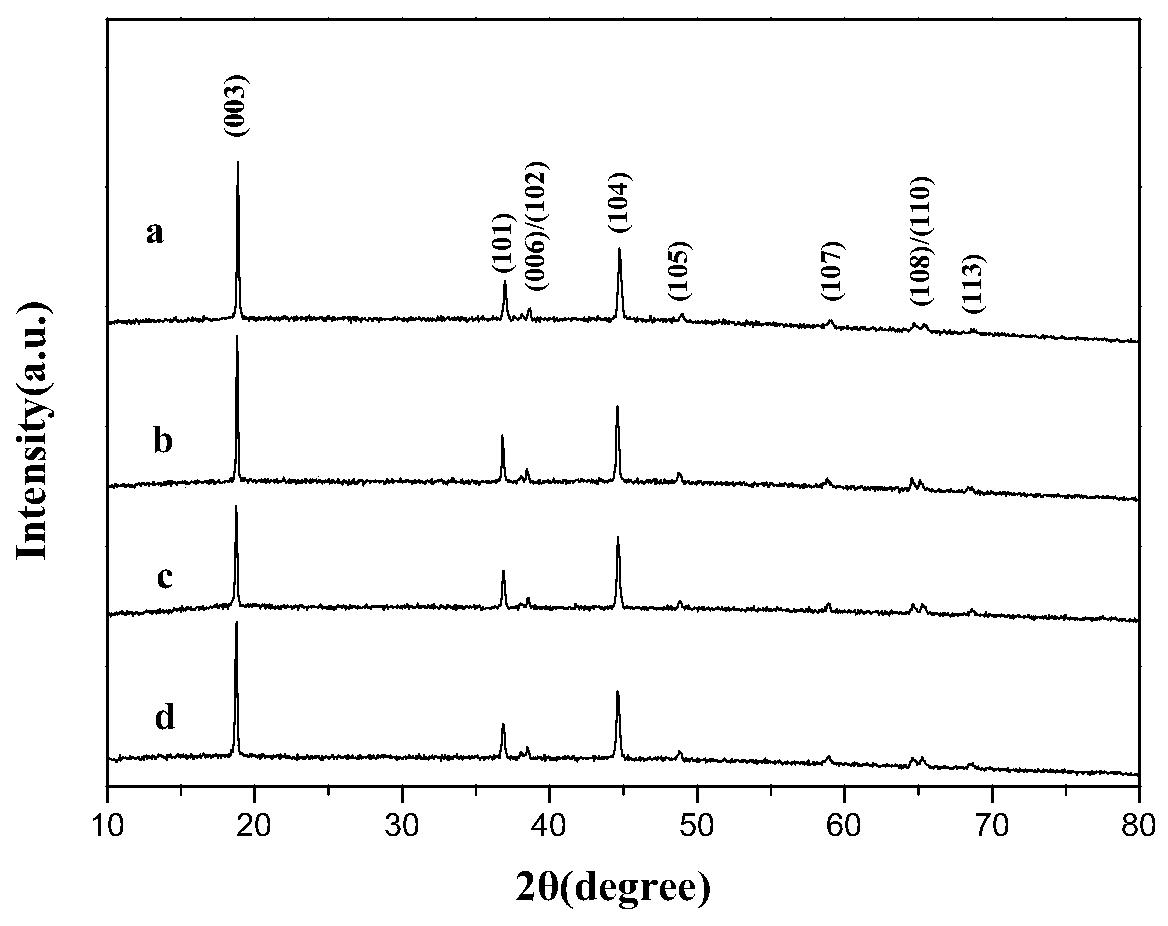

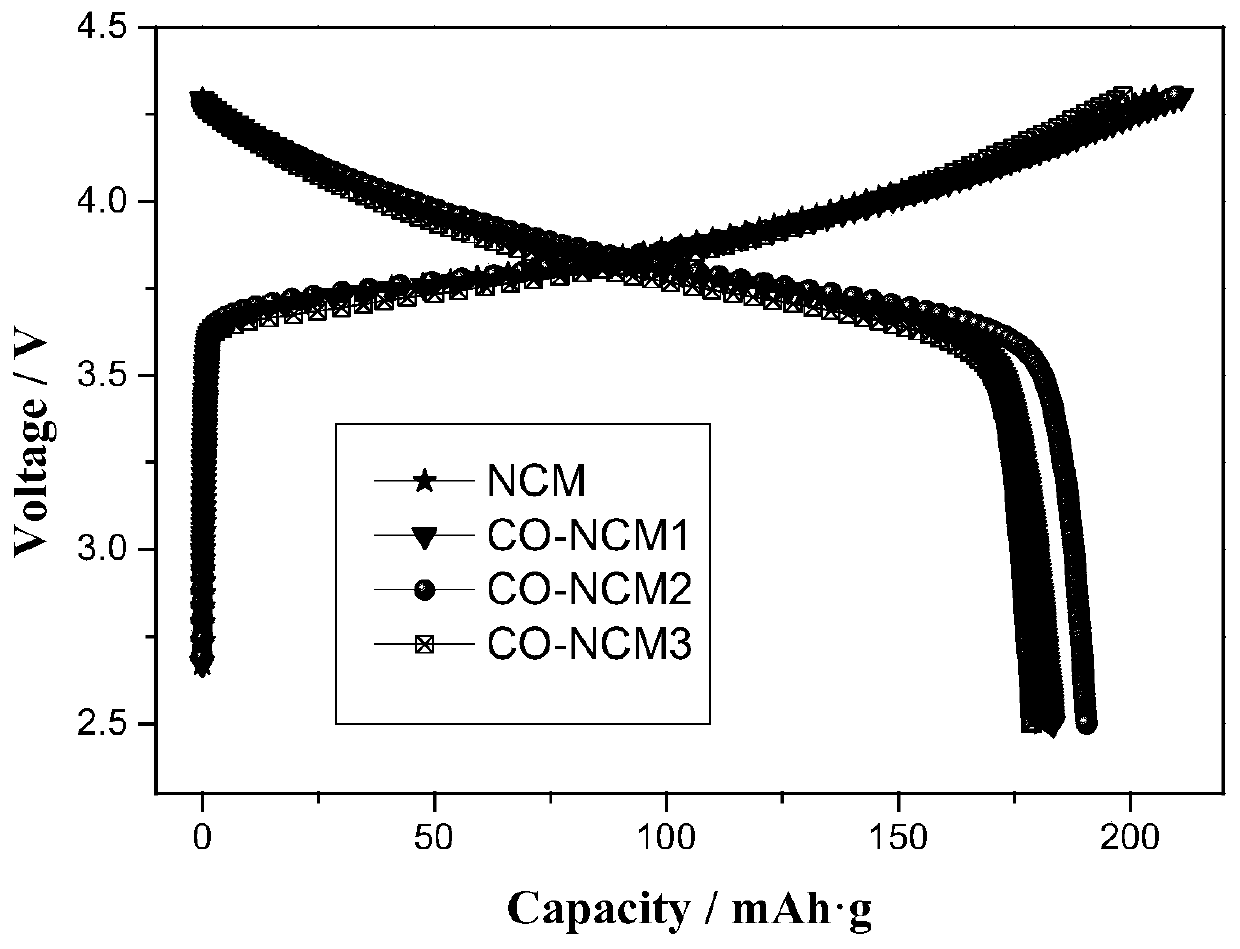

Embodiment 1

[0025] The target product of the present invention LiNi 0.6 co 0.2 mn 0.2 o 2 Prepared by the following steps:

[0026] (1) Co-precipitation method to synthesize stable Ni 0.6 co 0.2 mn 0.2 C 2 o 4 Precursor: Weigh 6.164g Ni(CH 3 COOH) 2 4H 2 O, 2.056gCo(CH 3 COOH) 2 4H 2 O, 2.002g Mn(CH 3 COOH) 2 4H 2 O was dissolved in the mixed solution of 60ml water and 60ml ethylene glycol, and weighed 6.240g C 2 h 2 o 4 2H 2 O and 0.2g of SDS were dissolved in another mixed solution of 60ml of water and 60ml of ethylene glycol, and the metal salt solution was slowly added dropwise to C under agitation. 2 h 2 o 4 2H 2 In the mixed solution of O and SDS, a light green precipitate is produced in the solution, and the stirring is continued for 6h;

[0027] (2) After stirring, put the solution into a hydrothermal kettle, place it in a muffle furnace, react at 200°C for 14h, wash by centrifugation, and dry overnight to obtain Ni 0.6 co 0.2 mn 0.2 C 2 o 4 Precursor;...

Embodiment 2

[0030] The target product of the present invention 1wt.%Co 3 o 4 coated LiNi 0.6 co 0.2 mn 0.2 o 2 Composite materials are produced by the following steps:

[0031] (1) Co-precipitation method to synthesize stable Ni 0.6 co 0.2 mn 0.2 C 2 o 4 Precursor: Weigh 6.164g Ni(CH 3 COOH) 2 4H 2 O, 2.056gCo(CH 3 COOH) 2 4H 2 O, 2.002g Mn(CH 3 COOH) 2 4H 2 O was dissolved in the mixed solution of 60ml water and 60ml ethylene glycol, and weighed 6.240g C 2 h 2 o 4 2H 2 O and 0.2g of SDS were dissolved in another mixed solution of 60ml of water and 60ml of ethylene glycol, and the metal salt solution was slowly added dropwise to C under agitation. 2 h 2 o 4 2H 2 In the mixed solution of O and SDS, a light green precipitate is produced in the solution, and the stirring is continued for 6h;

[0032] (2) After stirring, put the solution into a hydrothermal kettle, place it in a muffle furnace, react at 200°C for 14h, wash by centrifugation, and dry overnight to obta...

Embodiment 3

[0036] The target product of the present invention 3wt.% Co 3 o 4 coated LiNi 0.6 co 0.2 mn 0.2 o 2 Composite materials are produced by the following steps:

[0037] (1) Co-precipitation method to synthesize stable Ni 0.6 co 0.2 mn 0.2 C 2 o 4 Precursor: Weigh 6.164g Ni(CH 3 COOH) 2 4H 2 O, 2.056gCo(CH 3 COOH) 2 4H 2 O, 2.002g Mn(CH 3 COOH) 2 4H 2 O was dissolved in the mixed solution of 60ml water and 60ml ethylene glycol, and weighed 6.240g C 2 h 2 o 4 2H 2 O and 0.2g of SDS were dissolved in another mixed solution of 60ml of water and 60ml of ethylene glycol, and the metal salt solution was slowly added dropwise to C under agitation. 2 h 2 o 4 2H 2 In the mixed solution of O and SDS, a light green precipitate is produced in the solution, and the stirring is continued for 6h;

[0038] (2) After stirring, put the solution into a hydrothermal kettle, place it in a muffle furnace, react at 200°C for 14h, wash by centrifugation, and dry overnight to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com