Slurry for preparing negative electrode material and preparation method of negative electrode material

A technology of negative electrode material and slurry, applied in the field of preparation of slurry and negative electrode material, can solve problems such as poor comprehensive performance, and achieve the effect of enhancing battery safety performance, high rate performance, and improving rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

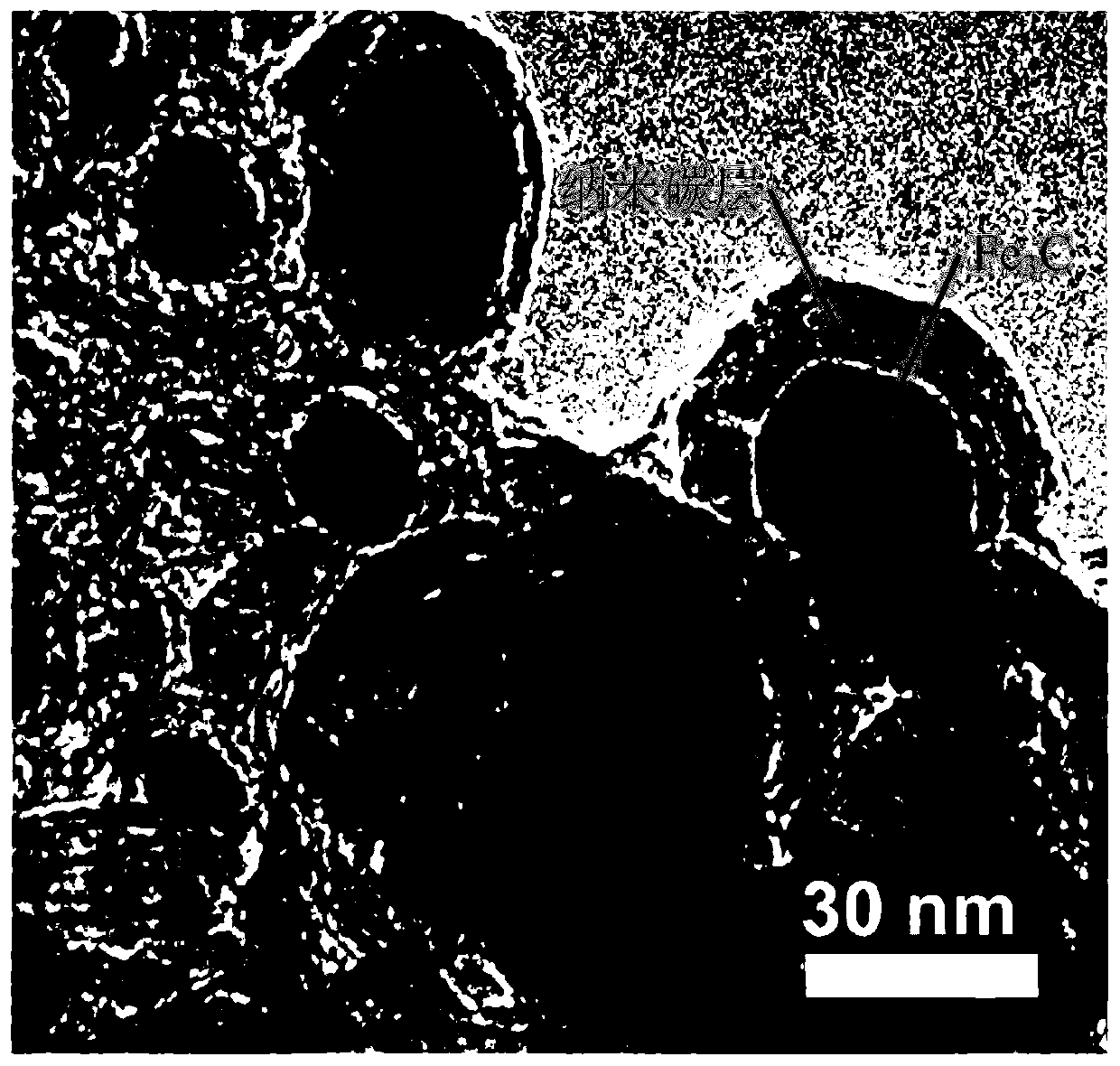

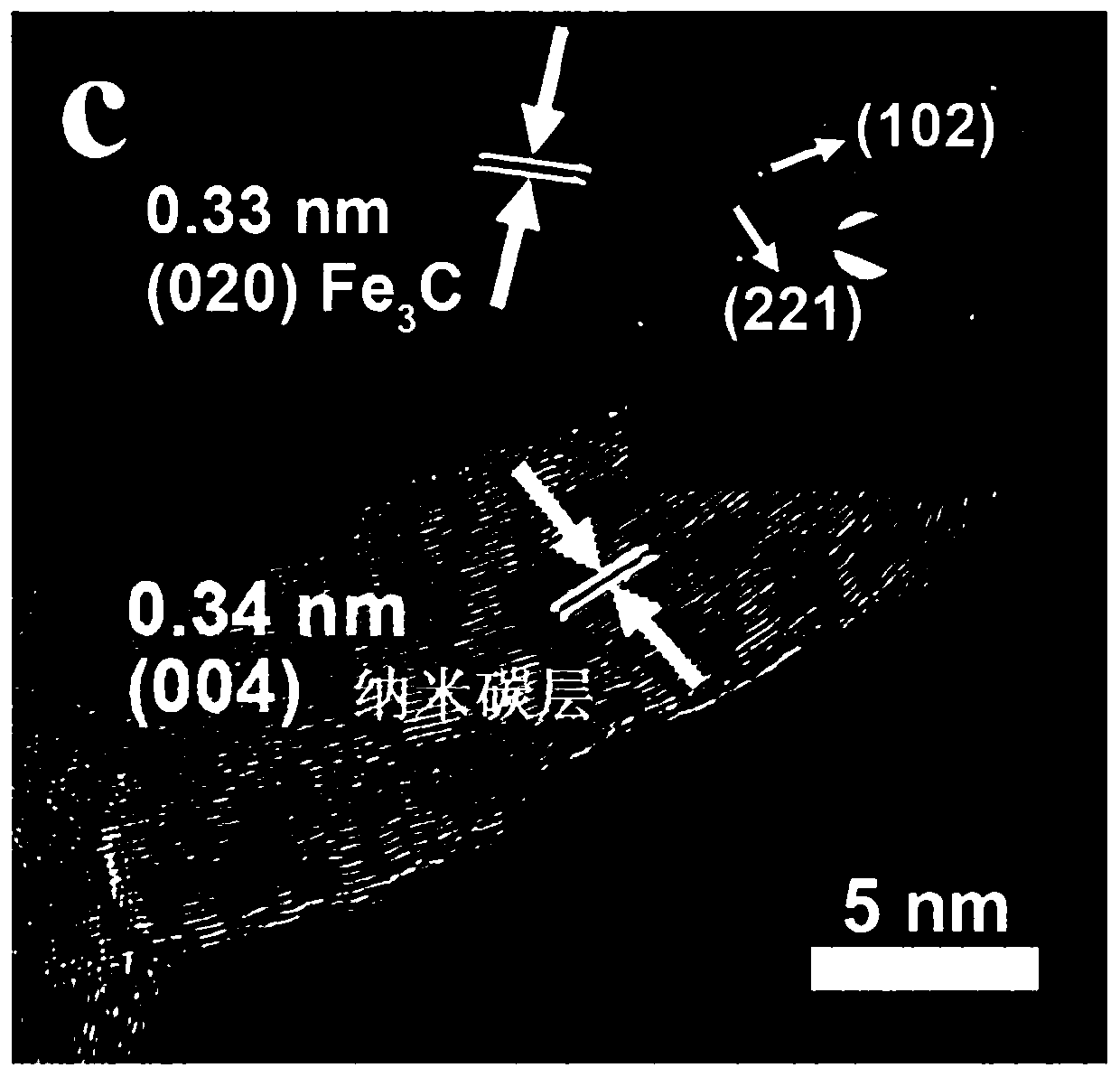

Image

Examples

Embodiment 1

[0034] The present invention provides a kind of slurry that prepares negative electrode material and the preparation method of negative electrode material, and described slurry comprises the following components of mass percentage:

[0035] Organic solvent 99.91%,

[0036] Active substance 0.09%;

[0037] The organic solvent is a combination of 50 wt% oleic acid and 50 wt% octadecene; the active substance is iron acetylacetonate.

[0038] The preparation method of described negative electrode material, comprises the following steps:

[0039] S1: Weigh the organic solvent and the active material according to the mass ratio, and put them in a container for mixing to obtain a slurry for preparing the negative electrode material of the lithium battery.

[0040] S2: Vacuumize the container containing the slurry for preparing the negative electrode material of the lithium battery in step S1 to a negative pressure of 3 kpa, and pass through argon gas after stabilizing at room tempe...

Embodiment 2

[0053] The present invention provides a kind of slurry that prepares negative electrode material and the preparation method of negative electrode material, and described slurry comprises the following components of mass percentage:

[0054] Organic solvent 99.6%,

[0055] Active substance 0.4%;

[0056] The organic solvent is a combination of 40wt% polyethylene glycol and 60wt% octadecene; the active substance is ferric hydroxide.

[0057] The preparation method of described negative electrode material, comprises the following steps:

[0058] S1: Weigh the organic solvent and the active material according to the mass ratio, and put them in a container for mixing to obtain a slurry for preparing the negative electrode material of the lithium battery.

[0059] S2: Vacuumize the container containing the slurry for preparing the lithium battery negative electrode material in step S1 to a negative pressure of 2 kpa, and pass it through argon gas after stabilizing at room temperat...

Embodiment 3

[0065] The present invention provides a kind of slurry that prepares negative electrode material and the preparation method of negative electrode material, and described slurry comprises the following components of mass percentage:

[0066] Organic solvent 95%,

[0067] active substance 5%;

[0068] The organic solvent is a combination of 60 wt% oleic acid and 40 wt% polyethylene glycol; the active substance is iron carbonyl.

[0069] The preparation method of described negative electrode material, comprises the following steps:

[0070] S1: Weigh the organic solvent and the active material according to the mass ratio, and put them in a container for mixing to obtain a slurry for preparing the negative electrode material of the lithium battery.

[0071] S2: Vacuumize the container containing the slurry for preparing the lithium battery negative electrode material in step S1 to a negative pressure of 3kpa, and pass it into argon after stabilizing at room temperature for 60 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com