Compound with ketone as core, preparation method and application of compound

A compound and general formula technology, applied in the application field of organic electroluminescent devices, can solve difficult problems such as high exciton utilization rate and high fluorescence radiation efficiency, low S1 state radiation transition rate, efficiency roll-off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

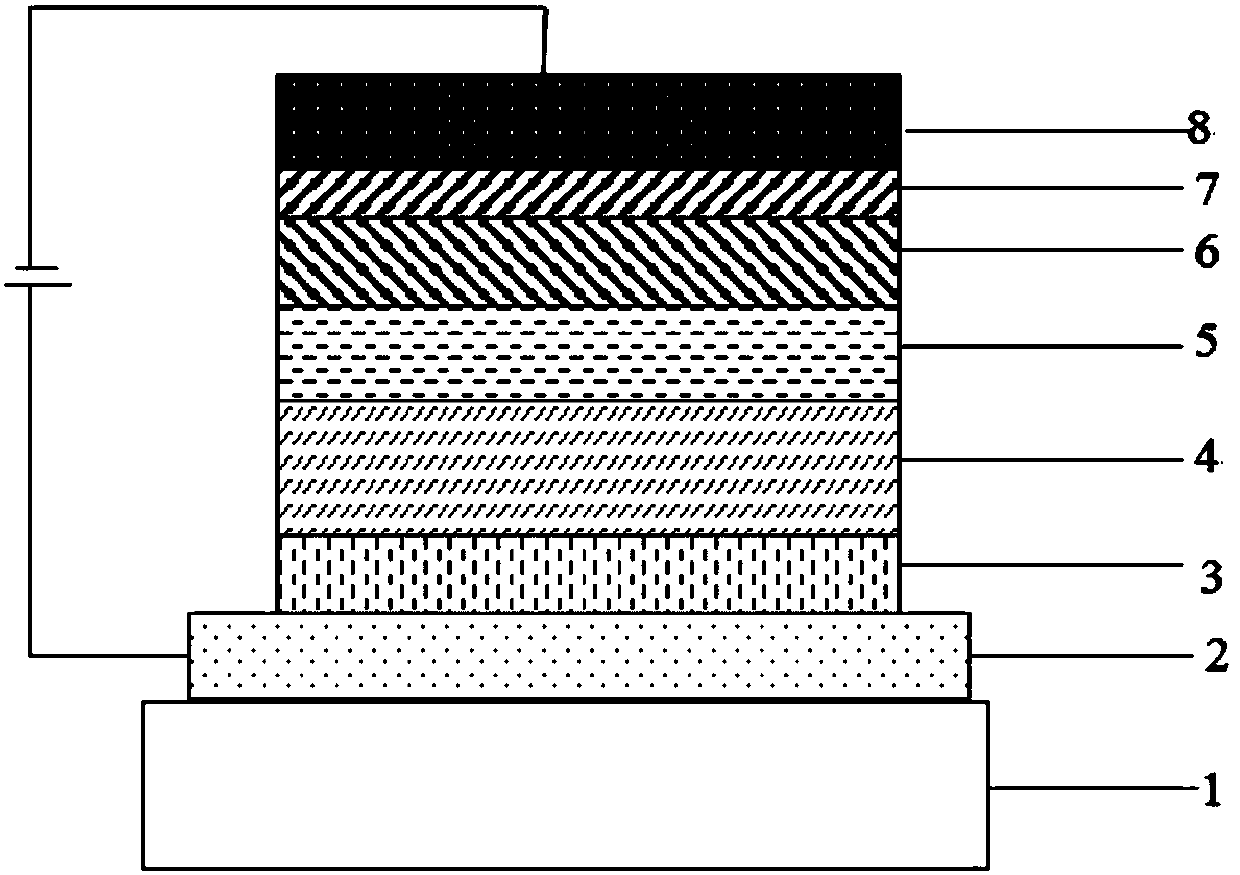

Image

Examples

Embodiment 1

[0191] Example 1 Preparation of Compound 1

[0192] Preparation of intermediate A1

[0193]

[0194] In a 250mL three-necked flask, blow nitrogen, add 0.01mol of raw material M-1, 0.012mol of raw material N-1, 150mL of toluene and ethanol mixed solvent (including toluene 100mL, ethanol 50mL), stir and mix, then add 0.02mol potassium carbonate Solution (2M), 1×10 -4 molPd(PPh 3 ) 4 , Heating to 120℃, refluxing reaction for 24h, sampling point plate, showing that no bromine is left, the reaction is complete; naturally cooled to room temperature, filtered, the filtrate was subjected to vacuum rotary evaporation (-0.09MPa, 85℃), and passed through a neutral silica gel column , To obtain intermediate I-1;

[0195] Dissolve 0.01 mol of intermediate I-1 in 100 mL of o-dichlorobenzene, add triphenylphosphine, react at 180°C for 12-24 hours, cool to room temperature after the reaction, filter, spin-evaporate the filtrate, and pass through a silica gel column to obtain Intermediate A1.

[019...

Embodiment 3

[0210] Example 3 Preparation of Compound 55

[0211] Preparation of intermediate C1

[0212]

[0213] In a 250mL three-necked flask, blow nitrogen, add 0.01mol intermediate A1, 0.012mol raw material K1, 150mL toluene, stir and mix, and then add 6×10 -5 mol Pd 2 (dba) 3 , 6×10 -5 mol of triphenylphosphine, 0.03mol of sodium tert-butoxide, heated to 105°C, refluxed for 24h, sampling point plate showed that no bromide remained, and the reaction was complete; naturally cooled to room temperature, filtered, and the filtrate was rotary evaporated to no distillate. Neutral silica gel column to obtain intermediate IIIx;

[0214] Under the protection of nitrogen, 0.01mol intermediate IIIx, 0.0075mol bis(pinacol) diboron, 0.0005molPd(dppf)Cl 2 , 0.025mol potassium acetate was dissolved in toluene, reacted at 105°C for 24h, sampling point plate, reaction was complete, natural cooling, filtration, and filtrate rotary evaporation to obtain crude product, pass through neutral silica gel column to ...

Embodiment 5

[0226] Example 5 Preparation of Compound 219

[0227]

[0228] The preparation method of compound 219 is the same as that of Example 2, except that intermediate A3 is substituted for intermediate A2. Elemental analysis structure (molecular formula C 33 H 17 N 3 O 3 ): Theoretical value: C, 78.72; H, 3.40; N, 8.35; O, 9.53; Test value: C, 78.72; H, 3.41; N, 8.35; O, 9.52. ESI-MS (m / z) (M+): The theoretical value is 503.52, and the measured value is 503.50.

[0229] The preparation process of Example 5 was repeated, and the following compounds were prepared through Examples 6-25, except that the raw materials I and Intermediate A listed in Table 9 below were used:

[0230] Table 9

[0231]

[0232]

[0233]

[0234]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com