Preparation method of sheepskin collagen oligopeptide

The technology of oligopeptide and collagen peptide is applied in the field of preparation of sheepskin collagen oligopeptide, which can solve the problems of easy environmental pollution and high viscosity, and achieve the effects of low cost, small molecular weight of oligopeptide and improved utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

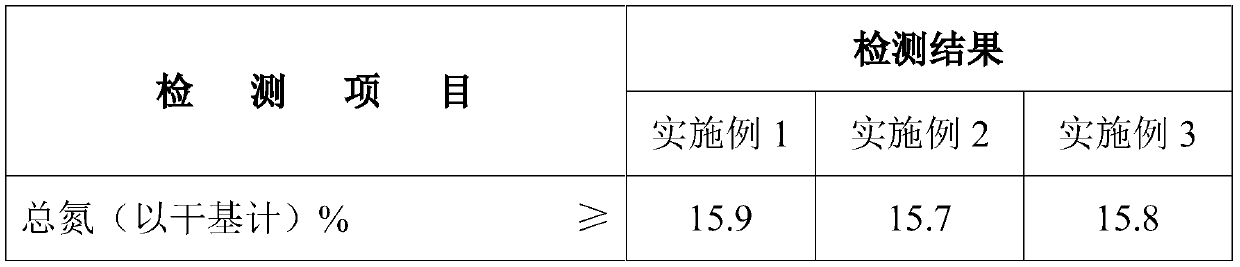

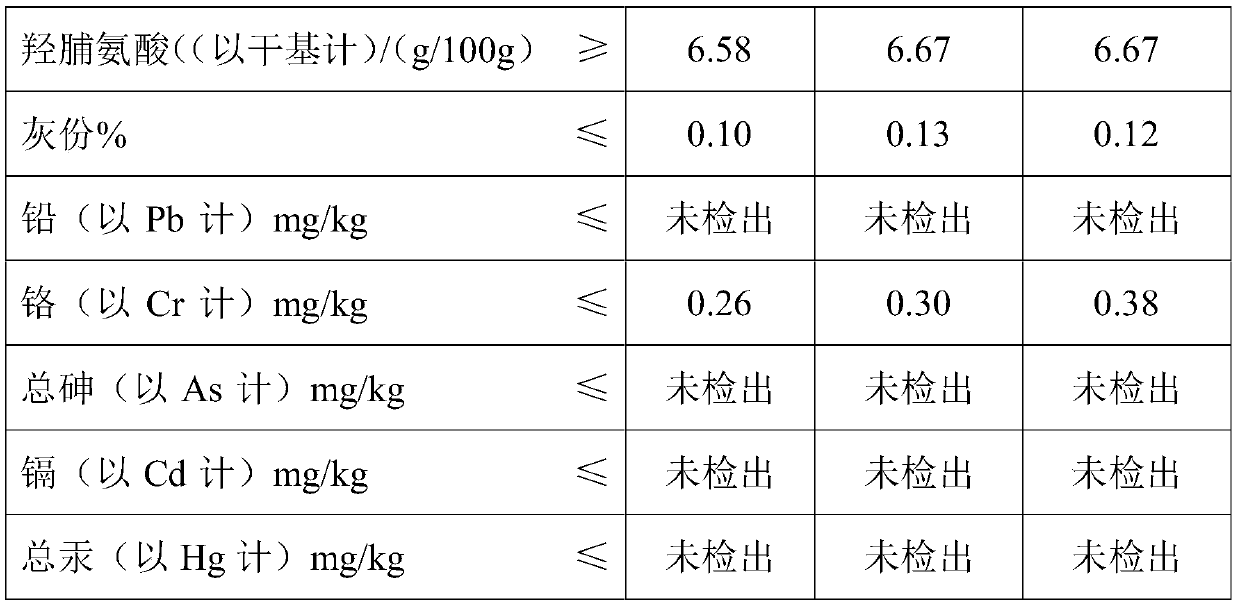

Embodiment 1

[0035] 1. For fresh sheepskin, use a shearing machine to cut the wool on the sheepskin to about 1cm.

[0036] 2. Use a meat remover to remove fat and meat from the sheepskin.

[0037] 3. Soak in hot water at 50°C for 40 minutes, and then use a hair removal machine to remove the remaining short hairs on the sheepskin.

[0038] 4. Use a crusher to break the sheepskin to about 1cm in diameter.

[0039] 5. Put the broken sheepskin into the reaction tank, add alkaline electrolyzed water twice the weight of the sheepskin, the pH of the electrolyzed water is 12.5, stir for 30 minutes to stabilize the pH of the feed liquid, raise the temperature to 80°C, and keep at 80°C 3 hours.

[0040] 6. Reduce the temperature in the tank to 45°C, add alkaline protease in an amount of 1.3% of the sheepskin weight, and perform enzymatic hydrolysis for 4 hours.

[0041] 7. Raise the temperature to 95°C and keep it for 20 minutes.

[0042] 8. Centrifuge with a decanter centrifuge to obtain a clar...

Embodiment 2

[0048] 1. For fresh sheepskin, use a shearing machine to cut the wool on the sheepskin to about 1cm.

[0049] 2. Use a meat remover to remove fat and meat from the sheepskin.

[0050] 3. Soak in hot water at 60°C for 20 minutes, and then use a hair removal machine to remove the remaining short hairs on the sheepskin.

[0051] 4. Use a crusher to break the sheepskin to about 1cm in diameter.

[0052] 5. Put the broken sheepskin into the reaction tank, add alkaline electrolyzed water three times the weight of the sheepskin, the pH of the electrolyzed water is 10.0, stir for 30 minutes to stabilize the pH of the feed liquid, raise the temperature to 75°C, and keep at 75°C 5 hours.

[0053] 6. Reduce the temperature in the tank to 55° C., add trypsin, and the amount of enzyme added is 0.8% of the sheepskin weight, and the enzyme is hydrolyzed for 5 hours.

[0054] 7. Raise the temperature to 90°C and keep it for 30 minutes.

[0055] 8. Centrifuge with a decanter centrifuge to ...

Embodiment 3

[0061] 1. For fresh sheepskin, use a shearing machine to cut the wool on the sheepskin to about 1cm.

[0062] 2. Use a meat remover to remove fat and meat from the sheepskin.

[0063] 3. Soak in hot water at 55°C for 30 minutes, and then use a hair removal machine to remove the remaining short hairs on the sheepskin.

[0064] 4. Use a crusher to break the sheepskin to about 1cm in diameter.

[0065] 5. Put the broken sheepskin into the reaction tank, add alkaline electrolyzed water 4 times the weight of the sheepskin, the pH of the electrolyzed water is 11.0, stir for 30 minutes to stabilize the pH of the feed liquid, raise the temperature to 80°C, and keep at 80°C 4 hours.

[0066] 6. Lower the temperature in the tank to 50°C, add a mixture of trypsin and alkaline protease (mass ratio 1:1), the total amount of enzyme added is 1.8% of the weight of sheepskin, and enzymatically hydrolyze for 3 hours.

[0067] 7. Raise the temperature to 95°C and keep it for 40 minutes.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com