Microwave heating L-type method for reducing composite strong mine pressure of thick hard roof and left coal pillar

A technology of microwave heating and leaving coal pillars, which is applied in ground mining, earthwork drilling, underground mining, etc., can solve the problems of cumbersome steps, serious working face, casualties, etc., and achieves high energy density, simple method, and easy operation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

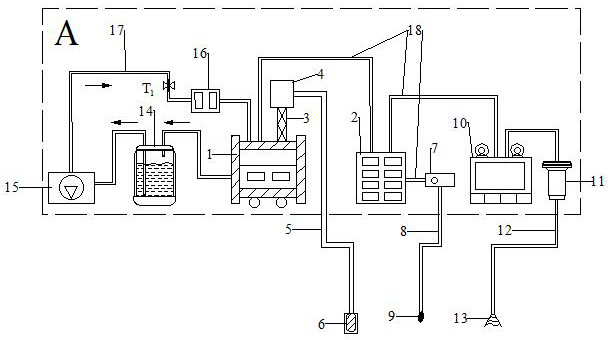

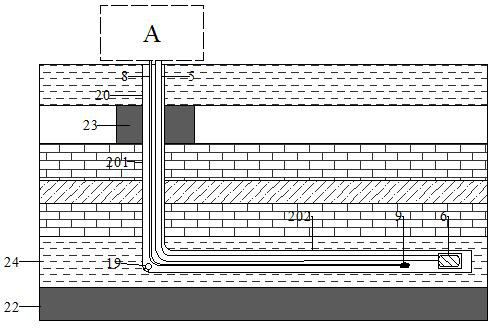

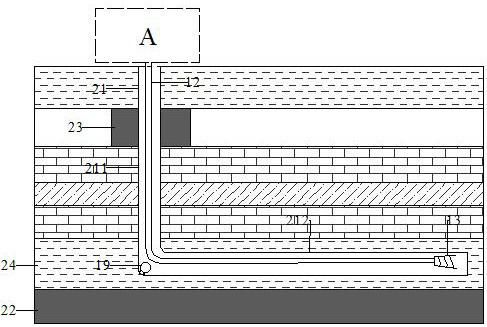

[0043] Such as figure 1 As shown, a microwave heating L-type device for reducing the thick and hard roof and the composite strong mine pressure of the left coal pillar includes: a high-power microwave generator, a microwave power controller, a circular waveguide, a waveguide converter, a coaxial waveguide, a microwave Transmitter, temperature monitor, high temperature resistant wire, temperature sensor, data acquisition instrument, signal amplifier, signal transmission line, detection probe, water storage tank, high pressure pump, cooler, microwave generator cooling control valve;

[0044] The high-power microwave generator 1 is connected to the microwave transmitter 6 through the circular waveguide 3, the waveguide converter 4, and the coaxial waveguide 5; the high-power microwave generator 1 passes the microwave energy through the circular waveguide 3, the waveguide converter 4, and the coaxial The waveguide 5 is delivered to the microwave launcher 6, and the microwave launc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com