Preparation method, preparation product and application of Mn7O13.5H2Oalpha-Fe2O3 composite

A mn7o13·5h2o, composite material technology, applied in nanotechnology for materials and surface science, hybrid/electric double layer capacitor manufacturing, hybrid capacitor electrodes, etc., which can solve complex operations, high energy consumption, time-consuming and laborious, etc. problem, to achieve the effect of simple operation, improving energy storage properties, saving time and energy and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

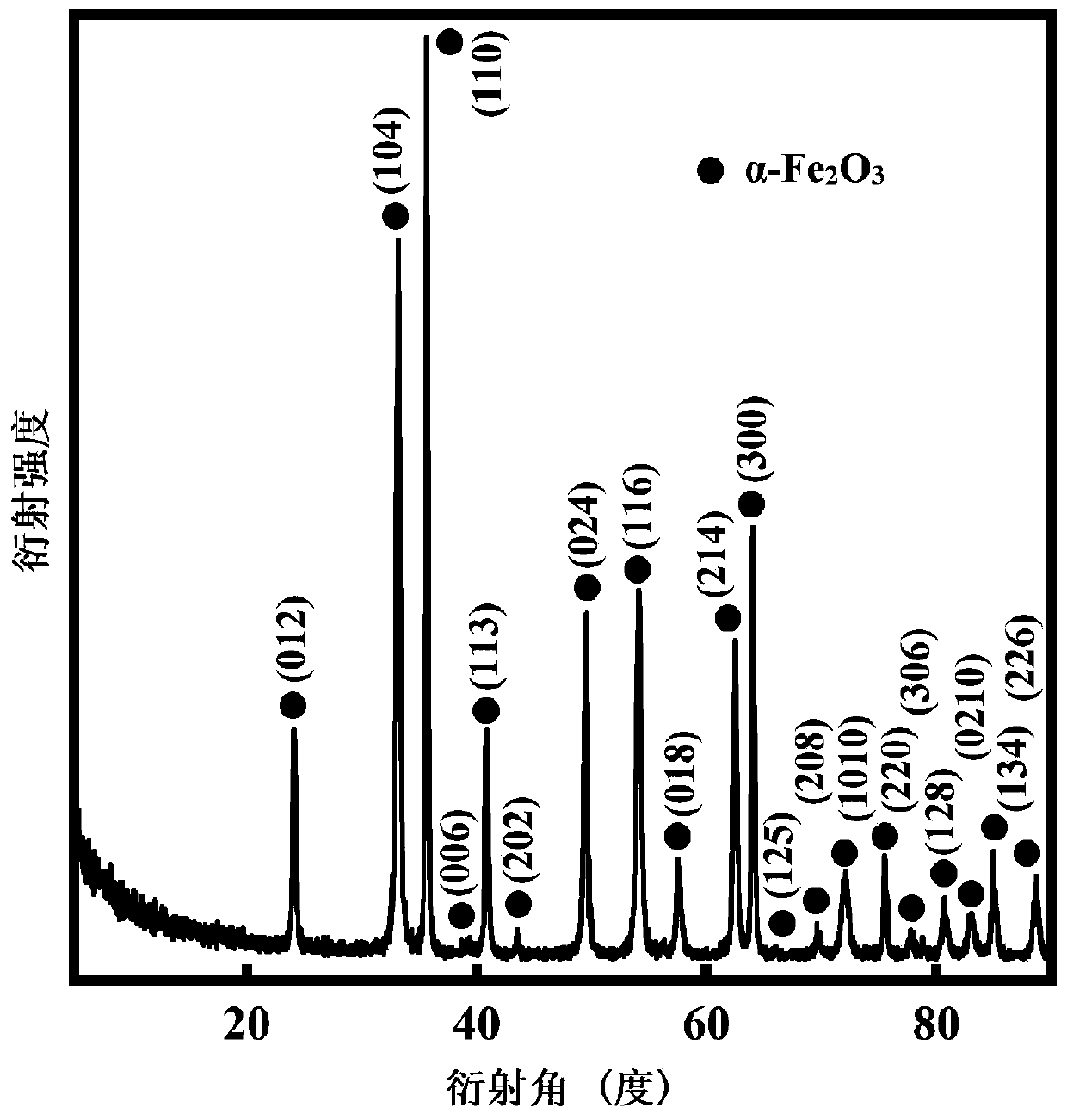

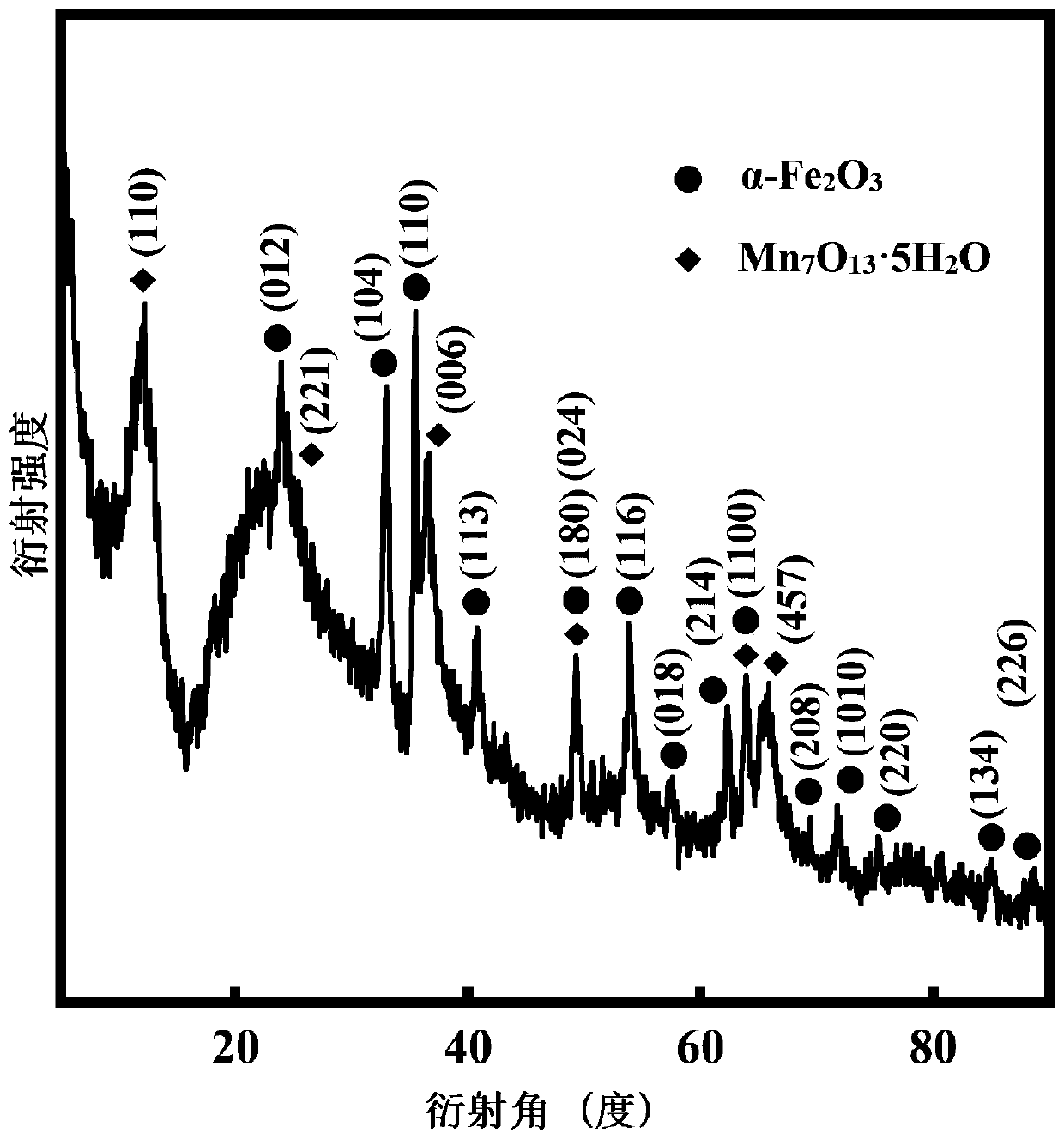

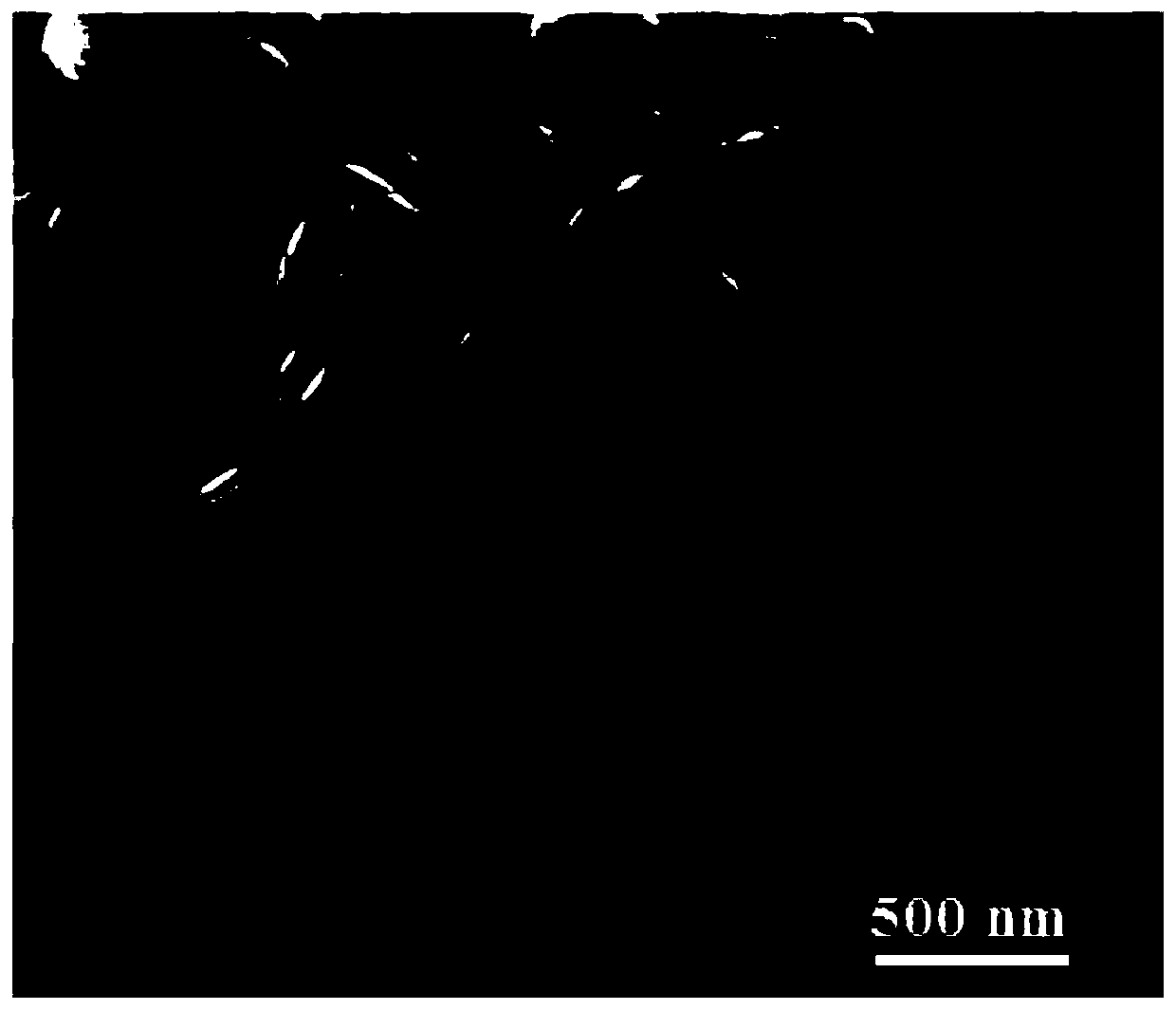

[0060] mn 7 o 13 ·5H 2 O / quasi-hexagonal α-Fe 2 o 3 Preparation of nanosheet composites

[0061] (1) Quasi-hexagonal α-Fe 2 o 3 Preparation of nanosheets

[0062] Weigh 20mmol of ferric nitrate (9 crystalline water) and place it in a round bottom flask, add 40ml of absolute ethanol and 5ml of deionized water, stir mechanically for 1h, then add 2.8g of sodium acetate, stir for 0.5h; pour the above mixed liquid into In a 50ml polytetrafluoroethylene-lined reactor, react at 180°C for 8h; after cooling, centrifuge, wash repeatedly with deionized water and absolute ethanol, and dry in a blast oven at 60°C for 12h to obtain α-Fe 2 o 3 Nanosheets;

[0063] (2) Quasi-hexagonal α-Fe 2 o 3 Crystallization of nanosheets

[0064] 0.2g quasi-hexagonal α-Fe2 o 3 Mix the nanosheets with 10g of analytically pure NaCl, grind them evenly in an agate mortar, put the evenly ground mixture into a ceramic crucible, and put it in a tube furnace for N 2 Calcination and crystallization u...

Embodiment 2

[0088] mn 7 o 13 ·5H 2 O / quasi-hexagonal α-Fe 2 o 3 Preparation of nanosheet composites

[0089] (1) Quasi-hexagonal α-Fe 2 o 3 Preparation of nanosheets

[0090] Weigh 20mmol ferric chloride into a round bottom flask, add 40ml absolute ethanol and 5ml deionized water, stir mechanically for 1h, then add 2.8g potassium acetate, stir for 0.5h; pour the above mixed liquid into 50ml polytetrafluoroethylene In a lined reactor, react at 180°C for 8h. After cooling, centrifuge, wash repeatedly with deionized water and absolute ethanol, and dry in a blast drying oven at 60°C for 12 hours;

[0091] (2) Quasi-hexagonal α-Fe 2 o 3 Crystallization of nanosheets

[0092] 0.2g quasi-hexagonal α-Fe 2 o 3 Nanosheets with 10 g of analytically pure Na 2 CO 3 Mix and grind thoroughly in an agate mortar, put the evenly ground mixture into a ceramic crucible, and calcine and crystallize it in a tube furnace under the protection of Ar gas. The heating conditions are as follows: heat...

Embodiment 3

[0097] mn 7 o 13 ·5H 2 O / quasi-hexagonal α-Fe 2 o 3 Preparation of nanosheet composites

[0098] (1) Quasi-hexagonal α-Fe 2 o 3 Preparation of nanosheets

[0099] Weigh 20mmol of ferric sulfate and put it in a round bottom flask, add 40ml of absolute ethanol and 5ml of deionized water, stir mechanically for 1h, then add 2.8g of sodium acetate, stir for 0.5h; pour the above mixed liquid into 50ml of polytetrafluoroethylene In a lined reactor, react at 180°C for 8h. After cooling, centrifuge, wash repeatedly with deionized water and absolute ethanol, and dry in a blast drying oven at 60°C for 12 hours;

[0100] (2) Quasi-hexagonal α-Fe 2 o 3 Crystallization of nanosheets

[0101] 0.2g quasi-hexagonal α-Fe 2 o 3 The nanosheets were mixed with 10 g of analytically pure KCl, and ground thoroughly and evenly in an agate mortar, and the evenly ground mixture was put into a ceramic crucible, and calcined and crystallized in a tube furnace under the protection of Ar gas. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com