Roasting processing technology of peanuts containing high protein

A processing technology and high-protein technology, which is applied to the functions of food ingredients, food ingredients as taste improvers, food science, etc., can solve the problems of not having protein and not being able to supplement, so as to maintain protein content and inhibit peeling , the effect of promoting regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

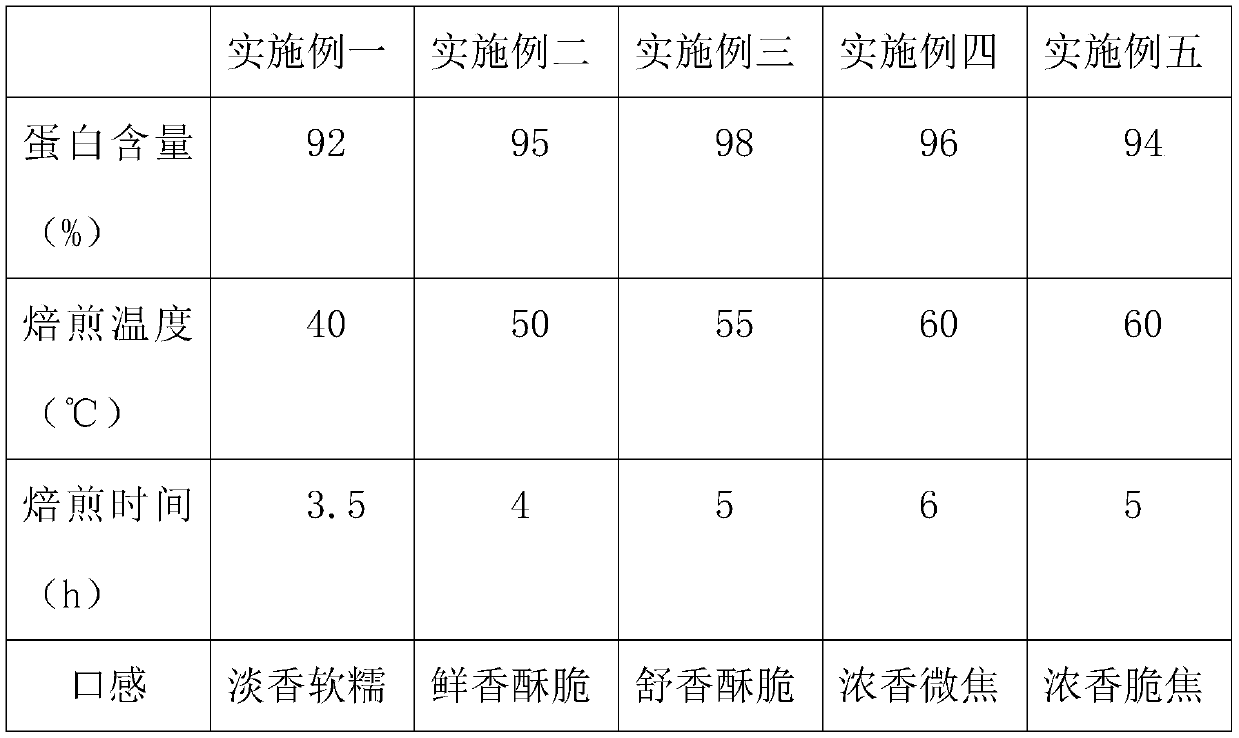

Embodiment 1

[0024] A kind of roasting process that contains high-protein peanut that the present invention proposes, comprises the following steps:

[0025] S1: Preparation of peanut kernels: Wash the peanuts without shells in clean water to remove surface impurities, then remove the peanuts without shells and drain, then peel off the shells of peanuts without shells, store and keep the peanut kernels separately, and then remove the peanut kernels Wash with clean water, remove and drain, then soak the peanut kernels in the pullulan aqueous solution for 5 minutes, remove and drain, and set aside;

[0026] S2: Weigh high-protein raw materials including the following parts by weight: 30 parts of milk, 45 parts of whey protein concentrate, 30 parts of meat, 28 parts of isomaltooligosaccharide, 35 parts of soybean protein isolate, 8 parts of dark chocolate, calcium caseinate 56 parts, protein coffee powder 32 parts, coconut powder 18 parts, glycerin 25 parts, phospholipids 54 parts, salt 36 pa...

Embodiment 2

[0031] A kind of roasting process that contains high-protein peanut that the present invention proposes, comprises the following steps:

[0032] S1: Preparation of peanut kernels: Wash the peanuts without shells in clean water to remove surface impurities, then remove the peanuts without shells and drain, then peel off the shells of peanuts without shells, store and keep the peanut kernels separately, and then remove the peanut kernels Wash with clean water, remove and drain, then soak the peanut kernels in the pullulan aqueous solution for 5 minutes, remove and drain, and set aside;

[0033] S2: Weigh high-protein raw materials including the following parts by weight: 40 parts of milk, 50 parts of whey protein concentrate, 35 parts of meat, 32 parts of isomaltooligosaccharide, 36 parts of soybean protein isolate, 11 parts of dark chocolate, calcium caseinate 43 parts, 25 parts of protein coffee powder, 13 parts of coconut powder, 18 parts of glycerin, 38 parts of phospholipid...

Embodiment 3

[0038] A kind of roasting process that contains high-protein peanut that the present invention proposes, comprises the following steps:

[0039] S1: Preparation of peanut kernels: Wash the peanuts without shells in clean water to remove surface impurities, then remove the peanuts without shells and drain, then peel off the shells of peanuts without shells, store and keep the peanut kernels separately, and then remove the peanut kernels Wash with clean water, remove and drain, then soak the peanut kernels in the pullulan aqueous solution for 8 minutes, remove and drain, and set aside;

[0040] S2: Weigh high-protein raw materials including the following parts by weight: 40 parts of milk, 55 parts of whey protein concentrate, 35 parts of meat, 38 parts of isomaltooligosaccharide, 40 parts of soybean protein isolate, 13 parts of dark chocolate, calcium caseinate 45 parts, protein coffee powder 27 parts, coconut powder 15 parts, glycerin 20 parts, phospholipids 44 parts, salt 30 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com