Method for separating chloropropene and chloropropane

A technology of allyl chloride and propane chloride, which is applied in the field of purifying allyl chloride, can solve the problems of increasing material handling capacity and complicated separation process, and achieve the effects of reducing equipment investment and energy consumption, good separation effect and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

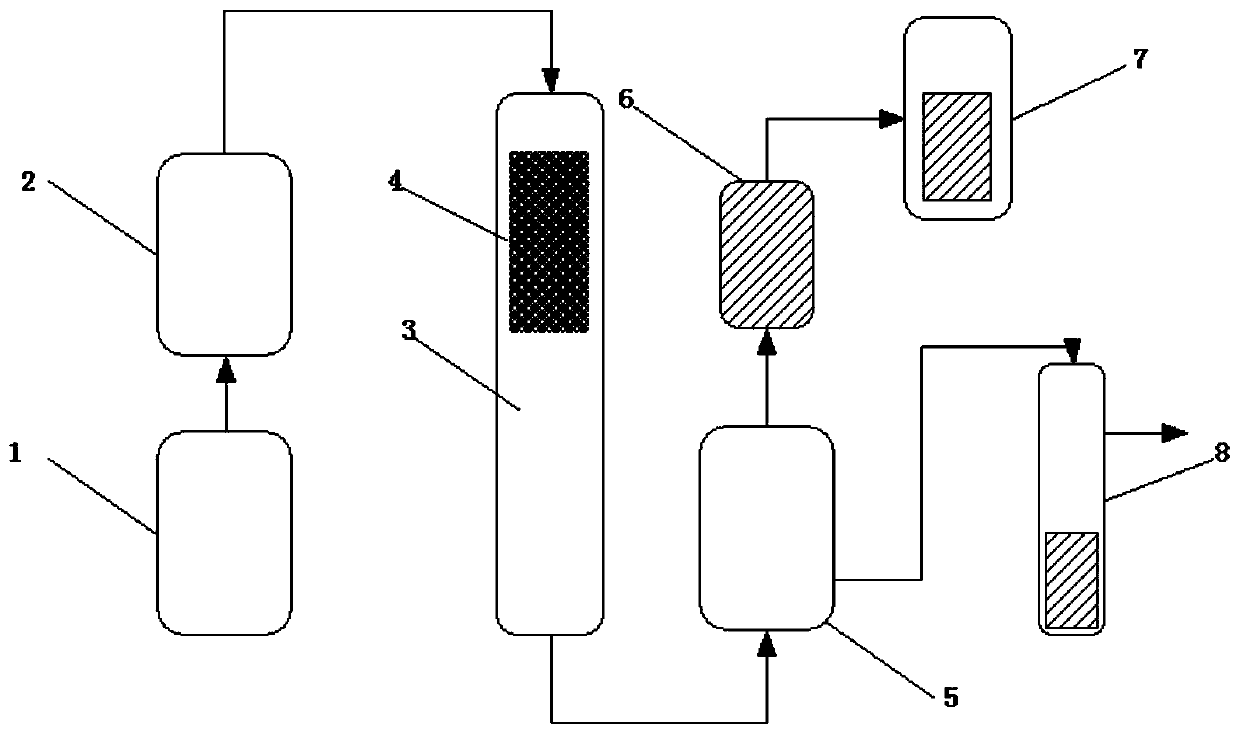

Method used

Image

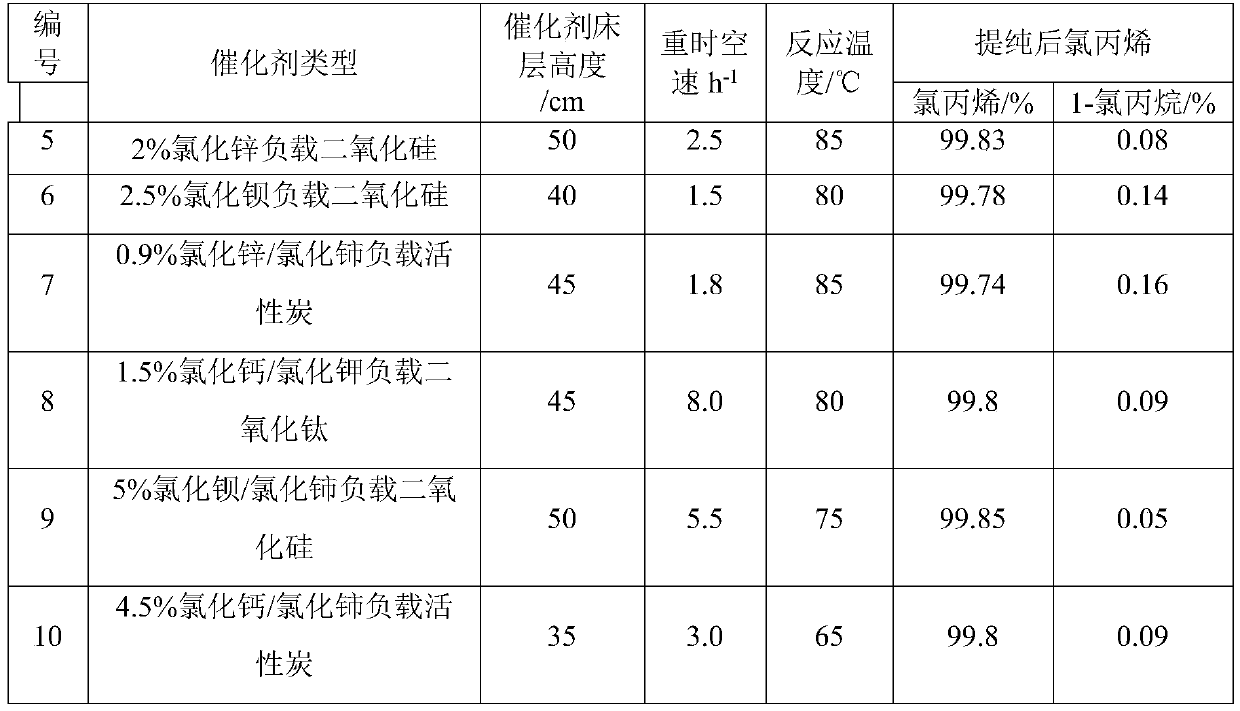

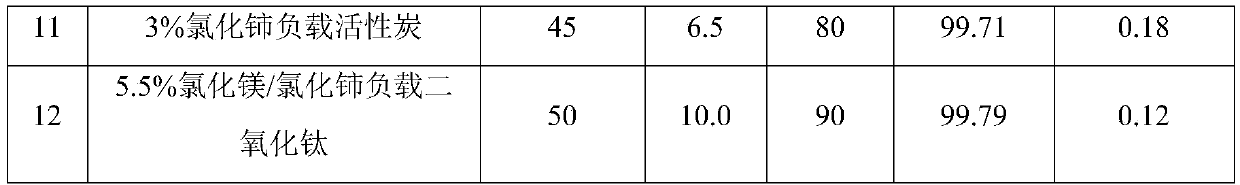

Examples

Embodiment 1

[0019] A 1000mL stainless steel pressure tank is filled with 300g of chloropropene containing 3% chloropropane, and the tank is heated to 80°C. The chloropropene gas enters the fixed bed reactor (the inner diameter of the tube is 3cm and the length is 80cm) from the gas phase pipeline at the top. The upper part is equipped with a 50cm catalyst bed, using 2% zinc chloride / barium chloride loaded activated carbon catalyst, according to the weight hourly space velocity of 1.5h -1 , Dehydrochlorination reaction occurs at 100°C. The reaction liquid flows from the bottom of the reactor to the extraction tank, the temperature of the jacket of the extraction tank is -5°C, and the generated propylene overflows from the gas phase of the extraction tank to the absorption tank; the absorption tank is filled with 300g of ethanol for absorbing propylene, and the jacket of the absorption tank The temperature is about -20°C; the material in the production tank is transferred to the stratifier,...

Embodiment 2

[0021] A 1000mL stainless steel pressure tank is filled with 350g of chloropropene containing 1.5% chloropropane, and the tank is heated to 70°C. The chloropropene gas enters the fixed-bed reactor (the inner diameter of the tube is 3cm and the length is 80cm) from the top gas phase pipeline. The upper part is equipped with a 45cm catalyst bed, using 1.5% cerium chloride supported silica catalyst, according to the weight hourly space velocity of 2.0h -1 , Dehydrochlorination reaction occurs at 110°C. The reaction liquid flows from the bottom of the reactor to the extraction tank, the temperature of the jacket of the extraction tank is -5°C, and the generated propylene overflows from the gas phase of the extraction tank to the absorption tank; the absorption tank is filled with 300g of ethanol for absorbing propylene, and the jacket of the absorption tank The temperature is about -20°C; the material in the production tank is transferred to the stratifier, and 200g of water is ad...

Embodiment 3

[0023] A 1000mL stainless steel pressure tank is filled with 385g of chloropropene containing 1.3% chloropropane, and the tank is heated to 90°C. The chloropropene gas enters the fixed-bed reactor (tube inner diameter 3cm, length 80cm) from the top gas phase pipeline, and the center of the reactor The upper part is equipped with a 40cm catalyst bed, using 0.8% magnesium chloride / zinc chloride supported titanium dioxide catalyst, according to the weight hourly space velocity of 2.4h -1 , Dehydrochlorination reaction occurs at 95°C. The reaction liquid flows from the bottom of the reactor to the extraction tank, the temperature of the jacket of the extraction tank is -5°C, and the generated propylene overflows from the gas phase of the extraction tank to the absorption tank; the absorption tank is filled with 300g of ethanol for absorbing propylene, and the jacket of the absorption tank The temperature is about -20°C; the material in the production tank is transferred to the lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com