Polysaccharide dressing for wound repairing and preparation method and application thereof

A wound repair and polysaccharide technology, applied in pharmaceutical formulations, pharmaceutical sciences, bandages, etc., can solve the problems of slow wound healing, frequent dressing changes, and easy generation of drug resistance, so as to promote healing, facilitate application, and promote chronic wound healing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

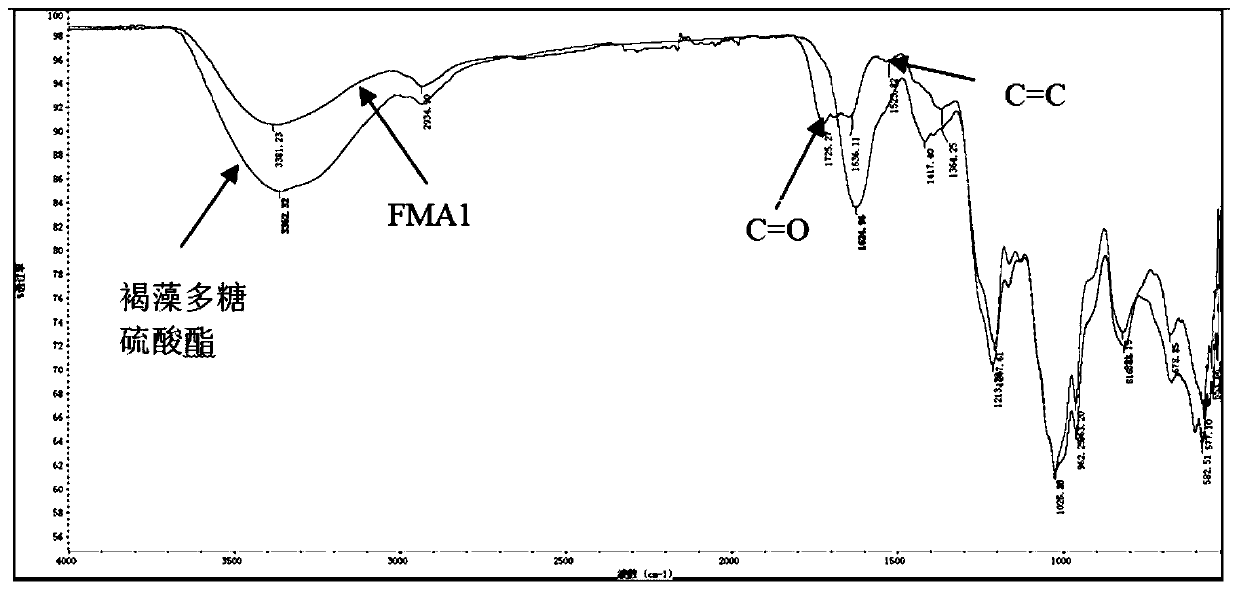

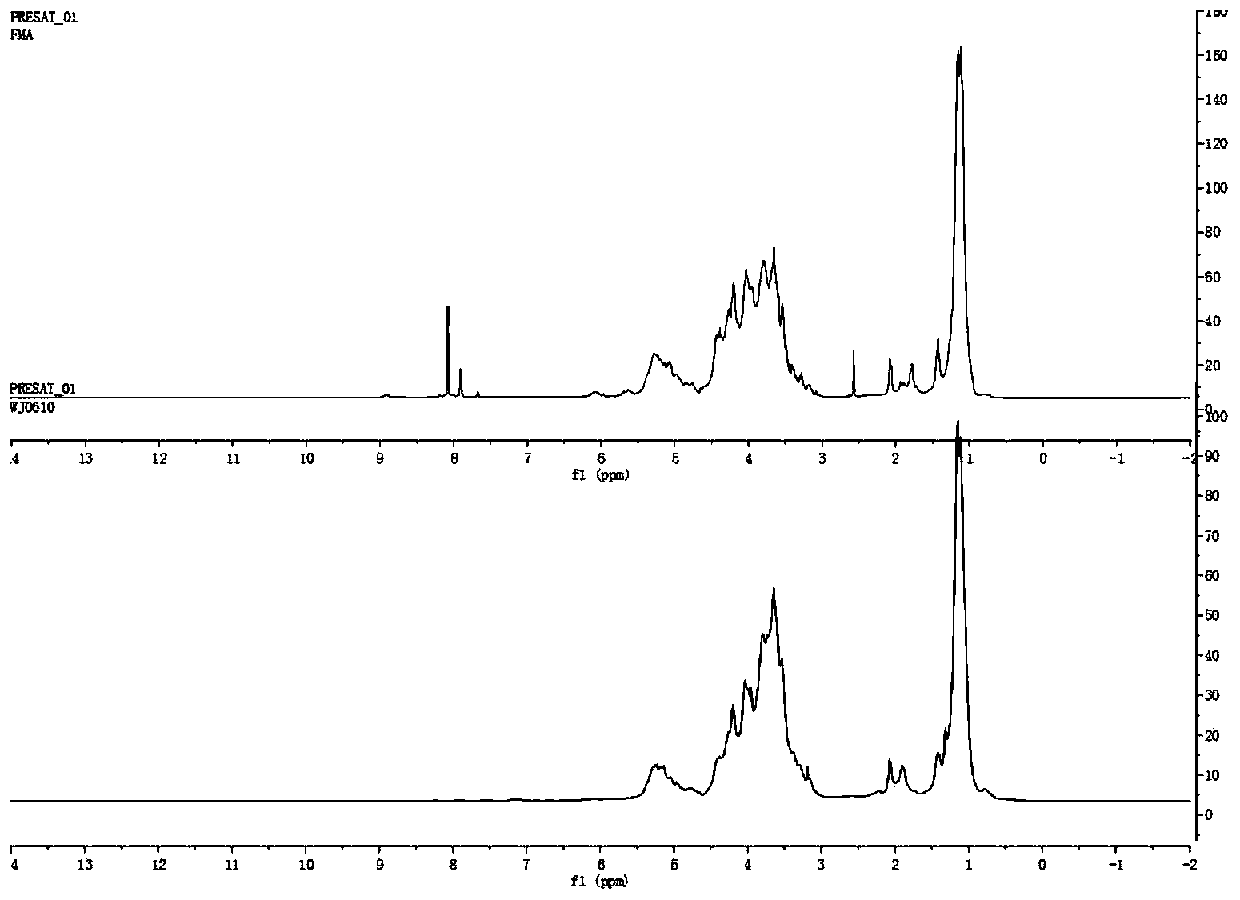

[0034] Embodiment 1, the preparation of fucoidan sulfate methacrylate derivative (FMA1)

[0035] Weigh 2 g of fucoidan sulfate, dissolve it in 100 mL of formamide, and stir evenly to prepare a 2% fucoidan sulfate solution. 12 mL of methacrylic anhydride containing 0.12 g of N-bromosuccinimide (NBS) was added dropwise to the polysaccharide solution, and reacted at 50° C. for 6 h. After the reaction was completed, the precipitate was precipitated with ethanol with a final concentration of 72%, and the precipitate was dissolved in water and dialyzed after drying. After 24 hours, the solution in the dialysis bag (dialysis is dialysis with a 3600Da dialysis bag, tap water for 24 hours, and distilled water for 24 hours) was concentrated under reduced pressure to 1 / 10 of the volume before concentration, and the concentrated solution was freeze-dried to obtain methyl Acrylylated fucoidan sulfate, denoted as FMA1.

Embodiment 2

[0036]Embodiment 2, the preparation of fucoidan sulfate methacrylate derivative (FMA2)

[0037] Weigh 2 g of fucoidan sulfate, dissolve it in 200 mL of formamide, and stir evenly to prepare a 1% fucoidan sulfate solution. 15 mL of methacrylic anhydride containing 0.15 g of N-bromosuccinimide (NBS) was added dropwise to the polysaccharide solution, and reacted at 80° C. for 2 h. After completion of the reaction, precipitate with ethanol with a final concentration of 75%, dissolve the precipitate in water and dialyze after drying. After 24 hours, the solution in the dialysis bag (dialysis is dialysis with a 3600Da dialysis bag, tap water for 24 hours, distilled water for 24 hours) is concentrated under reduced pressure, and the concentrated solution is freeze-dried to obtain methacrylylated fucoidan sulfate, which is designated as FMA2 .

Embodiment 3

[0038] Embodiment 3, the preparation of fucoidan sulfate methacrylate derivative (FMA3)

[0039] Weigh 2 g of fucoidan sulfate, dissolve it in 50 mL of formamide, and stir evenly to prepare a 4% fucoidan sulfate solution. 10 mL of methacrylic anhydride containing 0.10 g of N-bromosuccinimide (NBS) was added dropwise to the polysaccharide solution, and reacted at 40° C. for 8 h. After completion of the reaction, precipitate with ethanol with a final concentration of 80%, dissolve the precipitate in water and dialyze after drying. After 24 hours, dialysis (dialysis is performed with a 3600Da dialysis bag, tap water for 24 hours, distilled water for 24 hours) the solution in the bag is concentrated under reduced pressure, and the concentrated solution is freeze-dried to obtain methacrylylated fucoidan sulfate, which is designated as FMA3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com