Bone defect repair scaffold, and construction method and preparation method thereof, computer-readable storage medium and equipment

A construction method, bone defect technology, applied in calculation, 3D modeling, image data processing, etc., can solve the problem of porosity and pore shape affecting osseointegration effect, implant and bone elastic modulus mismatch, and lack of fracture healing biology To achieve good controllable pore size, good osseointegration effect, and favorable healing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] The third aspect of the present invention provides a preparation method of the bone defect repair scaffold described above, the preparation method comprising: constructing a bone defect repair scaffold model according to the construction method of the above bone defect repair scaffold model, and preparing a bone defect repair scaffold.

[0061] According to the reverse modeling of the patient's imaging (CT data and / or MRI data), a computer STL file is generated, and then the file is transferred to the program of the 3D printer to start printing. Printing process: Print layer by layer from bottom to top according to the STL file. The printing material is tantalum metal powder or tantalum alloy powder, and the whole process is carried out in an argon environment. First, a layer of tantalum metal powder or tantalum alloy powder is laid on the printed substrate, and then the laser print head of the printer emits a high-energy laser to melt the tantalum metal powder or tanta...

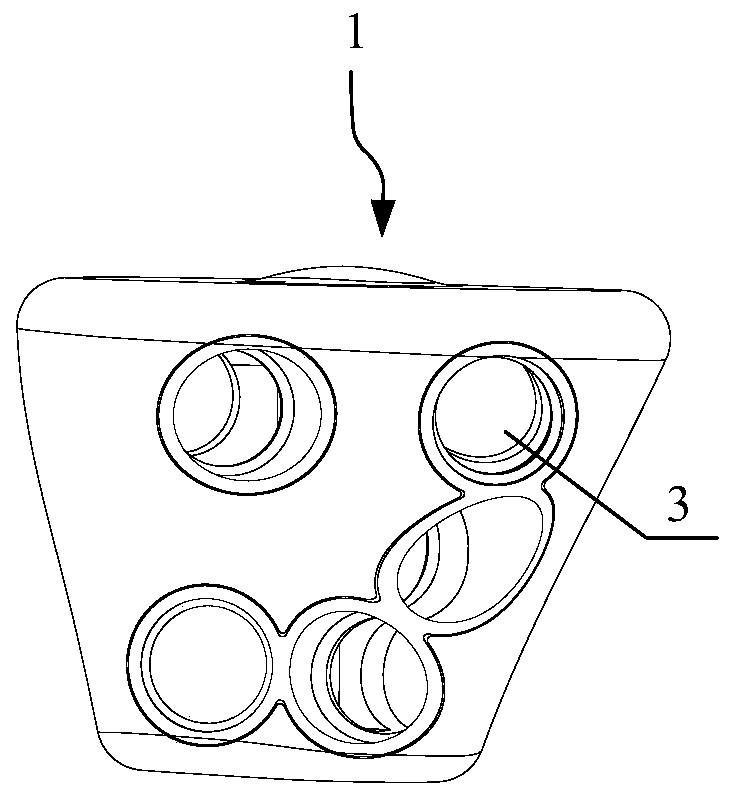

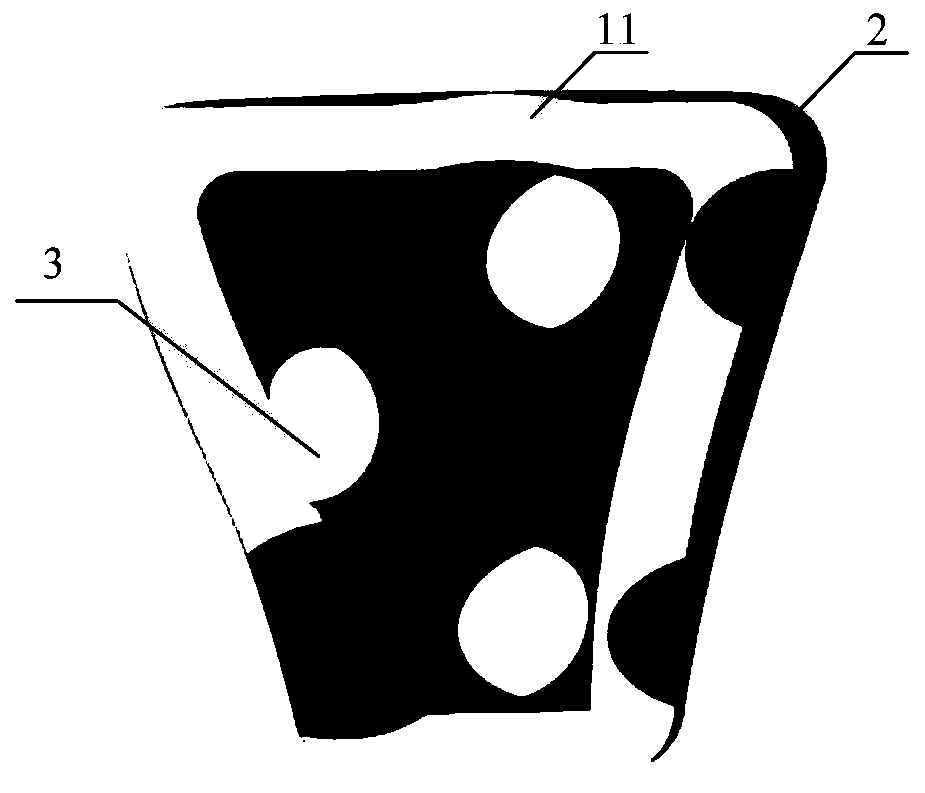

Embodiment 1

[0070] A bone defect repair bracket, comprising a bone defect repair bracket body 1 and a fusion surface layer 2, the fusion surface layer 2 is provided on the contact surface between the bone defect repair bracket body 1 and the bone, and the bone defect repair bracket body 1 has a hollow cavity 11, the fusion surface layer 2 is a porous structure, and the bone defect repair bracket is made of tantalum metal. The volume ratio of the hollow lumen 11 to the bone defect repair scaffold is 6:10. The shape of the bone defect repair bracket is the shape of the patient's bone defect. The porous structure is a layered structure of several layers, each layer of the layered structure has a plurality of micropores, and the micropores of the layers communicate with each other. The thickness of the fusion surface layer is 3.5 mm, the pore diameter of the fusion surface layer is 800 μm, and the porosity of the fusion surface layer is 70%. The bone defect repair bracket is provided with s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com