A fixed-point rotary cutting method for off-axis microlens processing

A technology of fixed-point rotation and cutting method, which is applied in the field of ultra-precision machining of microlens optical elements, which can solve the problems of difficult planning of cutting trajectory, reduction of off-axis microlens machining accuracy, unfavorable X-axis smooth movement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

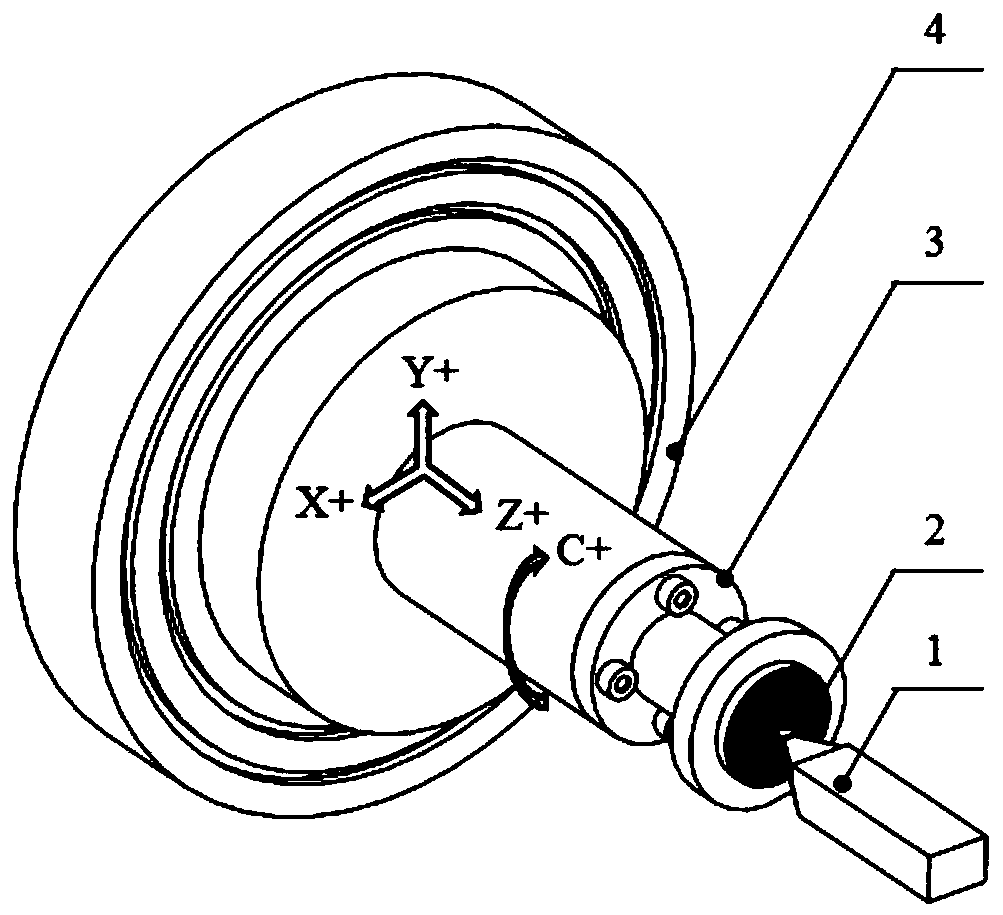

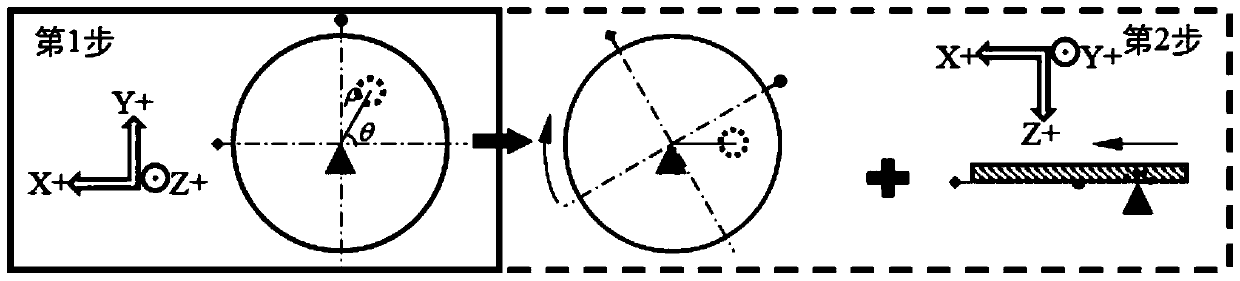

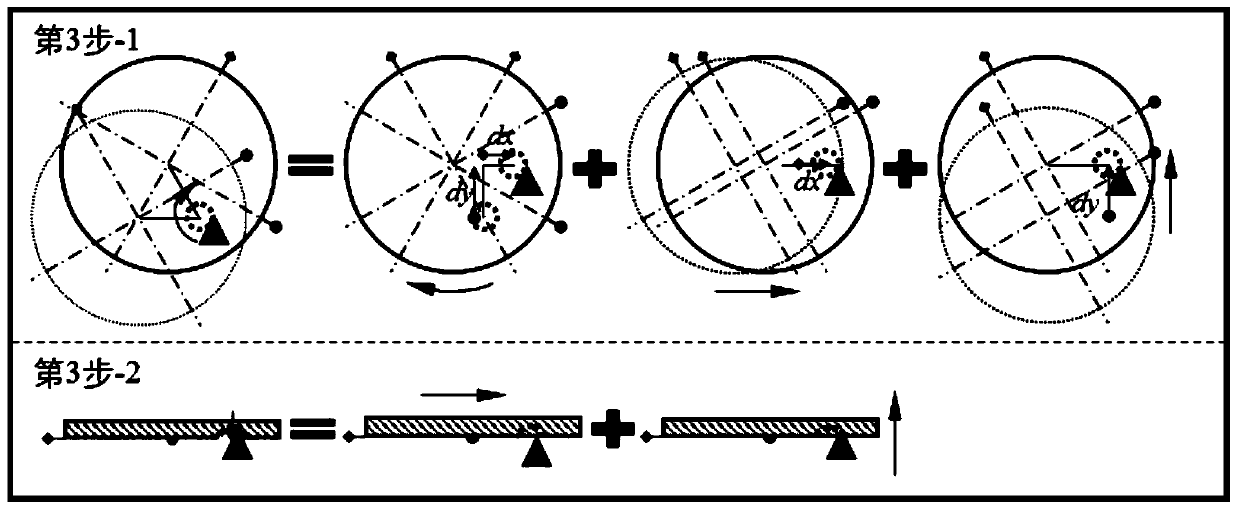

[0040] Specific implementation mode 1: Combination Figure 1 to Figure 4 To describe this embodiment, a fixed-point rotary cutting method for off-axis microlens processing in this embodiment includes the following steps:

[0041] Step 1: Adjust the distance between the center axis of the workpiece rotation and the axis of the ultra-precision machine tool spindle, so that the radial distance between the two axes is controlled within 0.5μm (inclusive); the workpiece 2 is glued to the fixture 3, and the fixture 3 is vacuum adsorbed on the ultra-precision machine tool The vacuum chuck 4; use the inductance micrometer or dial indicator that comes with the machine tool to measure the radial runout error of the cylindrical surface of the workpiece 2, and adjust the clamp 3 to make the workpiece 2 rotate by tapping in the radial direction with a leather hammer The radial circle runout error within one week is controlled within 0.5μm (inclusive);

[0042] Step two, use the trial cutting me...

specific Embodiment approach 2

[0055] Specific implementation manner two: combination Figure 1 to Figure 4 To explain this embodiment, the fixed-point rotary cutting method of this embodiment is suitable for processing various types of materials. For example, in step 1, the material of the processed part can be either a plastic material used as a mold, such as duralumin 6061, mold steel, electroless nickel, etc., or a brittle material used as a separate part product, such as single Crystal germanium, single crystal silicon, etc. This setting enables the processing method to have a wider range of materials. The other composition and connection relationship are the same as in the first embodiment.

[0056] In step 1 of this embodiment, the material of the processed part is a plastic material or a brittle material; the type of the micro lens unit of the processed part is a concave mirror or a convex mirror.

specific Embodiment approach 3

[0057] Specific implementation mode three: combination Figure 1 to Figure 4 To illustrate this embodiment, a variety of processing tools of different shapes and materials can be selected in this embodiment. For example, in step 2, the tool material used can be single crystal diamond, nano twin diamond, or polycrystalline diamond and other tool materials used for ultra-precision processing of optical elements. The shape of the tool used can be either a formed turning tool or a non-formed turning tool, such as a circular arc cutting tool, a linear cutting tool and a pointed tool. If the tool used is a circular arc turning tool, the radius of the tool tip arc should not be greater than the minimum curvature radius of the microlens profile generatrix. This setting enables the machining method to have more flexible tool parameter settings and expands the scope of application of the method. Other components and connection relationships are the same as those in the first or second ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com