Metal/composite material multilayer double-gradient energy-absorbing vibration-damping sandwich structure and preparation method thereof

A composite material, sandwich structure technology, applied in metal layer products, chemical instruments and methods, synthetic resin layer products, etc., can solve the problem that the interlayer unit cell structure does not have functional gradient effect, etc. The preparation method is simple, the designability is strong, and the effect of improving the performance of buffering and vibration reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A method for preparing a metal / composite multi-layer double-gradient energy-absorbing vibration-damping sandwich structure is as follows:

[0035] (1) According to the size of the unit cell structure, design and prepare metal gradient hollow tubular unit cell structures with different relative densities through the rolling and cutting process;

[0036] (2) Prepare the metal / composite material panel required for the multi-layer double-gradient energy-absorbing vibration-damping sandwich structure, and polish and clean the surface;

[0037] (3) Design and manufacture the molds required for the unit cell structure of composite materials;

[0038] (4) Roll composite material prepregs with different gradient configurations on the mould, close the mould, heat and pressurize to a suitable temperature and pressure and keep it for a period of time;

[0039] (5) cooling to room temperature, demolding after depressurization, cutting and polishing the end of the gradient unit cell...

Embodiment 1

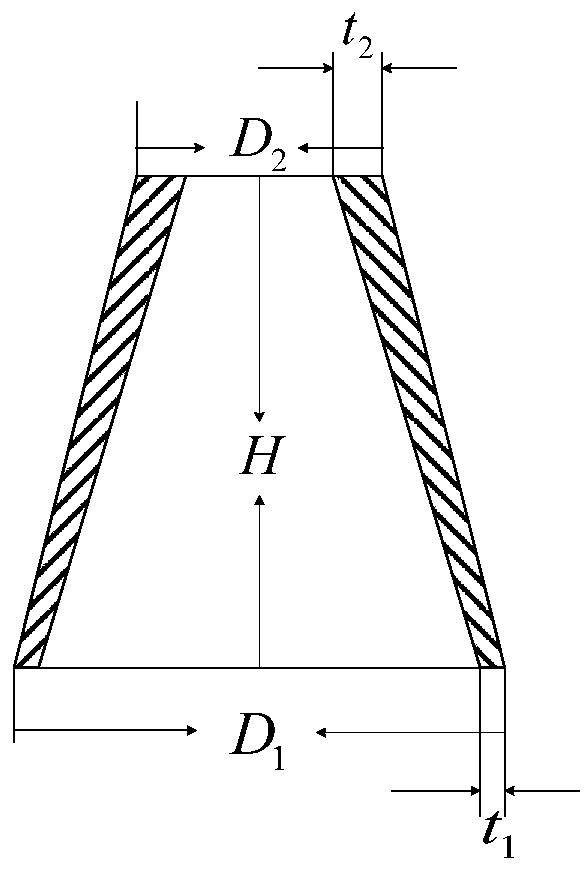

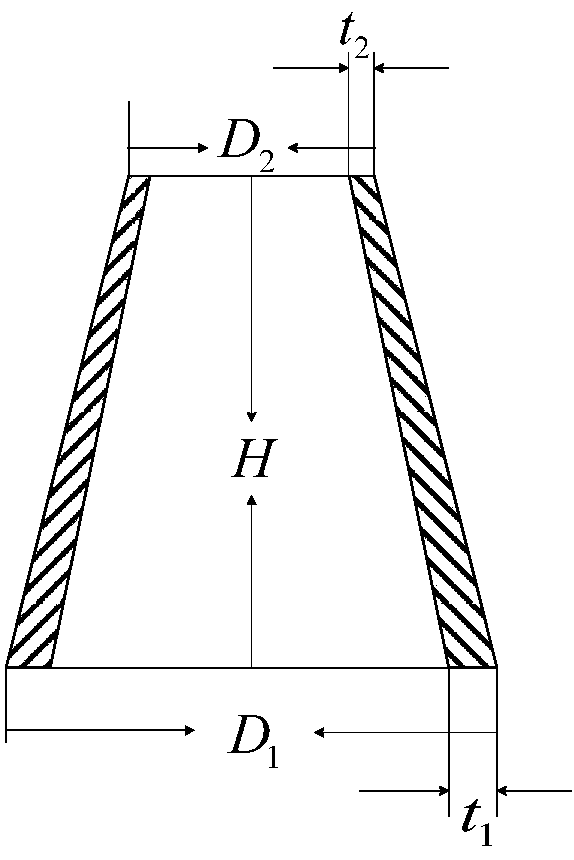

[0051] Fig. 1 is a schematic axial cross-sectional view of each layer of unit cell structure with an axial gradient in an embodiment provided by the present invention. Among them, H is the height of the unit cell structure, which also determines the height of the core layer where the unit cell structure is located, and D 1 is the outer diameter of the bottom of the unit cell structure, D 2 is the outer diameter of the top of the unit cell structure, t 1 is the wall thickness at the bottom of the unit cell structure, t 2 is the top wall thickness of the unit cell structure. The hollow conical tubes A and B given in the figure are t 1 and t 2 As a variable, the designed axial gradient unit cell structure; the hollow conical tube C is at t 1 and t 2 When equal, by laying 3 layers of different materials, the radial gradient unit cell structure is designed.

[0052]Referring to Fig. 1, the relative density of the unit cell structure can be designed by adjusting any parameter...

Embodiment 2

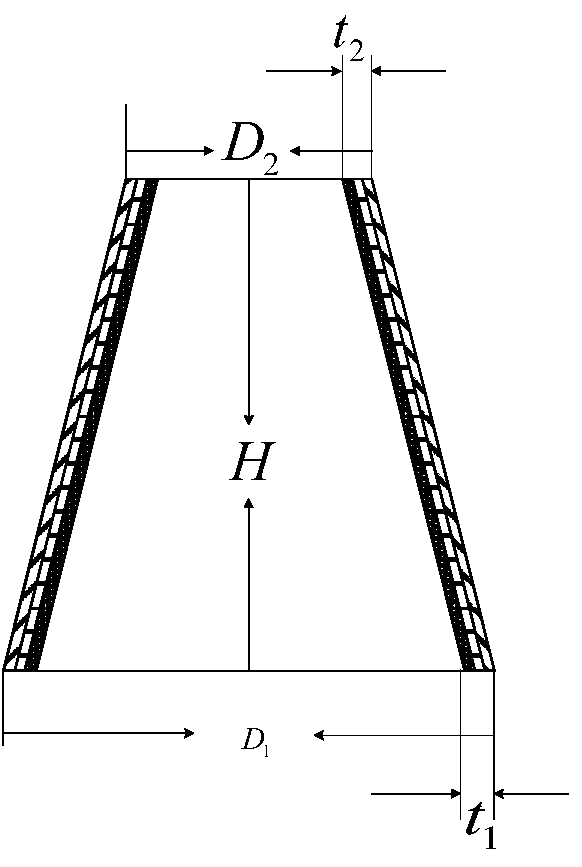

[0066] Fig. 2 is a schematic axial cross-sectional view of each layer of unit cell structure with an axial gradient in another embodiment provided by the present invention. The meanings of the parameters are the same as those in Figure 1, and the hollow tube E is t 1 and t 2 As a variable, the designed axial gradient unit cell structure; the hollow tube F is at t 1 and t 2 When equal, by laying 3 layers of different materials, the radial gradient unit cell structure is designed.

[0067] Referring to Fig. 2, the relative density of the composite unit cell structure can be designed by adjusting any parameters. The hollow tube F given in Fig. 2 is at t 1 and t 2 When equal, by laying 3 layers of different materials, the radial gradient unit cell structure is designed. The multi-layer dual-gradient energy-absorbing and vibration-damping sandwich structure prepared by assembling and fixing the unit cell and the panel is shown in Fig. 4(b).

[0068] Therefore, the preparation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com