Method for efficiently treating southern high-water-content cow dung to prepare organic fertilizer

A high moisture content, organic fertilizer technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of high energy consumption and processing costs of processing equipment, difficulty in maintenance, and reduced efficiency of organic fertilizers, etc., to save secondary renewable resources , Improve fermentation efficiency and increase specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

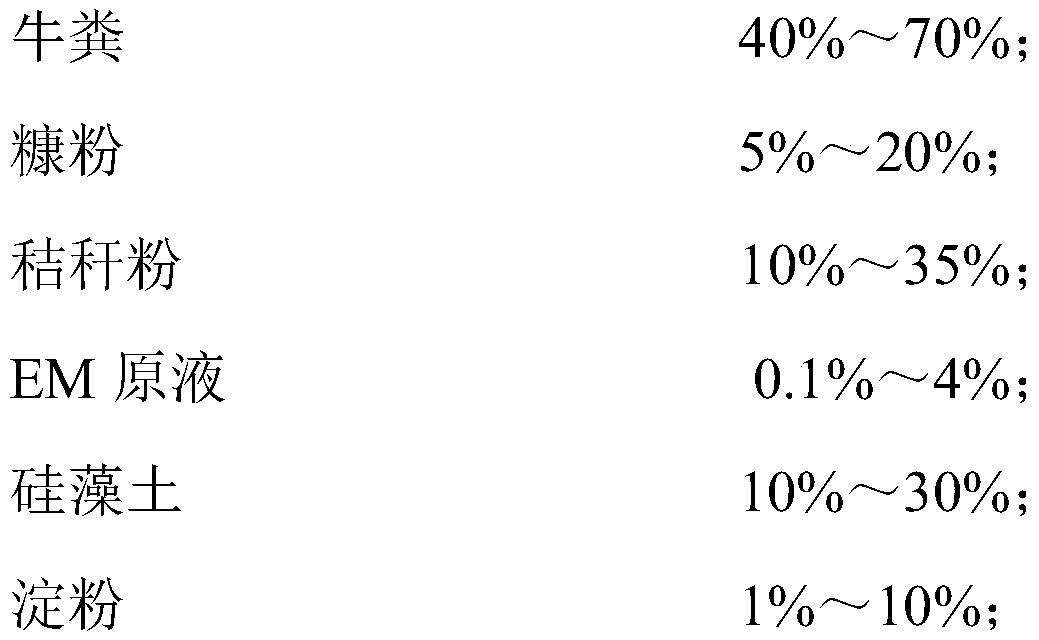

[0039] A kind of high-efficiency treatment cow dung organic fertilizer with high moisture content in the south provided by the present embodiment comprises the following components by weight percentage:

[0040]

[0041]

[0042] The preparation method of this organic fertilizer is as follows:

[0043] (1) Prepare raw materials: Prepare raw materials according to the above formula ratio;

[0044] (2) Primary mixing: first mix starch and 5% diatomaceous earth evenly, then evenly spray 0.5% EM stock solution in the mixture, and let it stand for 0.5 hours, so that the EM stock solution is fully absorbed;

[0045] (3) Secondary mixing: uniformly mix the remaining materials with the primary mixing;

[0046] (4) Anaerobic fermentation: The above raw materials are compacted and piled up, and sealed anaerobic fermentation is carried out for 4 days, so that the fermentation temperature is kept between 45°C and 75°C. At this time, most of the harmful pathogenic microorganisms hav...

Embodiment 2

[0050] A kind of high-efficiency treatment cow dung organic fertilizer with high moisture content in the south provided by the present embodiment comprises the following components by weight percentage:

[0051]

[0052] The preparation method of this organic fertilizer is as follows:

[0053] (1) Prepare raw materials: Prepare raw materials according to the above formula ratio;

[0054] (2) Primary mixing: first mix starch and 7% diatomaceous earth evenly, then evenly spray 0.4% EM stock solution in the mixture, and let it stand for 1 hour, so that the EM stock solution is fully absorbed;

[0055] (3) Secondary mixing: uniformly mix the remaining materials with the primary mixing;

[0056] (4) Anaerobic fermentation: The above raw materials are compacted and piled up, and sealed anaerobic fermentation is carried out for 3 days, so that the fermentation temperature is kept between 45°C and 75°C, and most of the harmful pathogenic microorganisms have been killed at this tim...

Embodiment 3

[0060] A kind of high-efficiency treatment cow dung organic fertilizer with high moisture content in the south provided by the present embodiment comprises the following components by weight percentage:

[0061]

[0062] The preparation method of this organic fertilizer is as follows:

[0063] (1) Prepare raw materials: Prepare raw materials according to the above formula ratio;

[0064] (2) Primary mixing: first mix starch and 8% diatomaceous earth evenly, then evenly spray 0.8% EM stock solution in the mixture, and leave it for 2 hours to make the EM stock solution fully absorbed;

[0065] (3) Secondary mixing: uniformly mix the remaining materials with the primary mixing;

[0066] (4) Anaerobic fermentation: The above raw materials are compacted and piled up, and sealed anaerobic fermentation is carried out for 5 days, so that the fermentation temperature is kept between 45°C and 75°C, and most of the harmful pathogenic microorganisms have been killed at this time , an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com