Preparation method of aging-free high-strength and high-ductility aluminum alloy based on large deformation homogenization

A homogenization and large deformation technology, which is applied in the field of aluminum alloy processing, can solve problems such as difficulty in shortening the production cycle of alloys, and achieve the effects of increasing solid solubility, promoting dissolution, and reducing deformation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

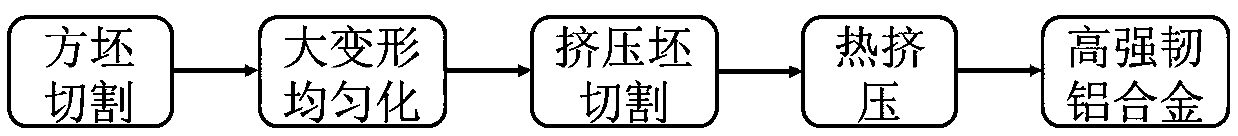

Method used

Image

Examples

Embodiment 1

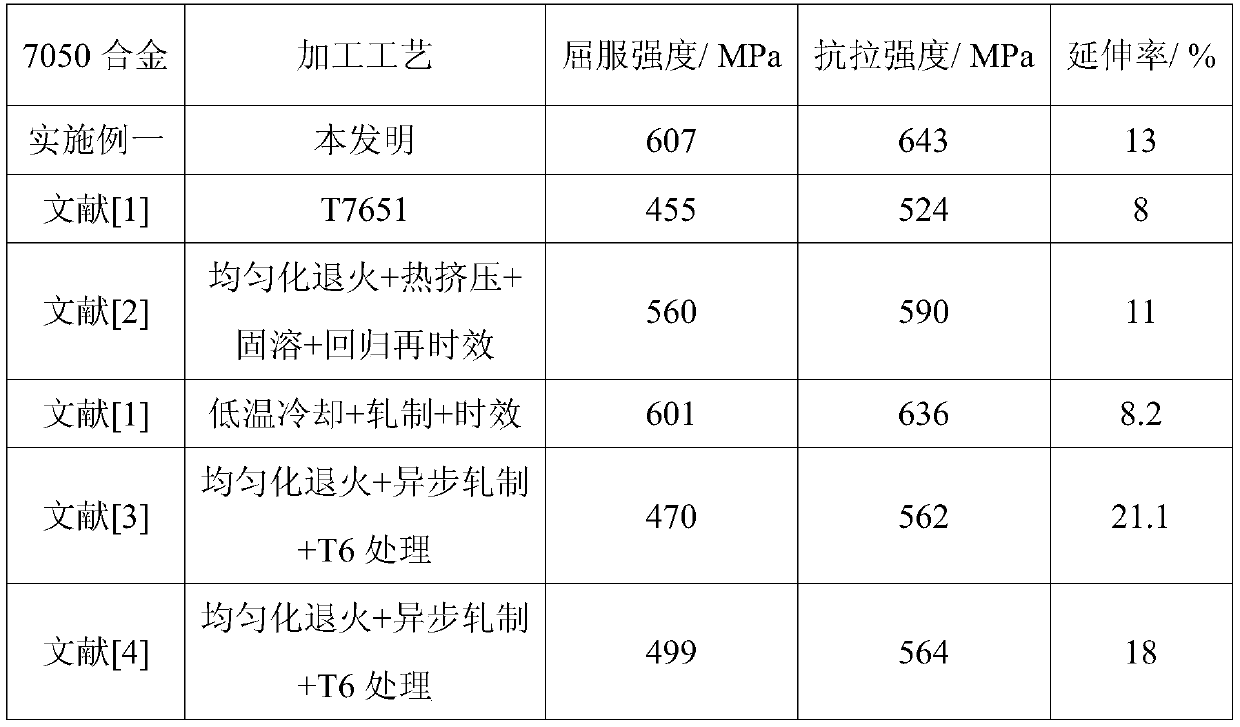

[0027] Cut a billet with a size of 50mm×50mm×100mm from a 7050 aluminum alloy ingot; place the billet in a rotary equal-channel angular extrusion die, and perform 8-pass continuous equal-channel angular extrusion at a temperature of 450°C processing, followed by water quenching to obtain a supersaturated solid solution block extrusion billet; cutting out an alloy rod with a diameter of 45mm from the above block extrusion billet, the length direction of the alloy rod is parallel to the direction of equal channel corner extrusion; for the alloy The rod is subjected to hot extrusion processing, the extrusion temperature is 350°C, the extrusion speed is 0.8m / min, and the extrusion ratio is 15. After extrusion, it is water quenched to obtain an aging-free high-strength aluminum alloy based on large deformation homogenization.

Embodiment 2

[0029] Cut a billet with a size of 50mm×50mm×100mm from a 7050 aluminum alloy ingot; place the billet in a rotary equal-channel angular extrusion die, and perform 6-pass continuous equal-channel angular extrusion at a temperature of 480°C processing, followed by water quenching to obtain a supersaturated solid solution block extrusion billet; cutting out an alloy rod with a diameter of 45mm from the above block extrusion billet, the length direction of the alloy rod is parallel to the direction of equal channel corner extrusion; for the alloy The rod is subjected to hot extrusion processing, the extrusion temperature is 320°C, the extrusion speed is 0.6m / min, and the extrusion ratio is 20. After extrusion, it is water-quenched to obtain an aging-free high-strength aluminum alloy based on large deformation homogenization.

Embodiment 3

[0031] Cut a billet with a size of 50mm×50mm×100mm from a 7050 aluminum alloy ingot; place the billet in a rotary equal-channel angular extrusion die, and perform 7-pass continuous equal-channel angular extrusion at a temperature of 470°C processing, followed by water quenching to obtain a supersaturated solid solution block extrusion billet; cutting out an alloy rod with a diameter of 45mm from the above block extrusion billet, the length direction of the alloy rod is parallel to the direction of equal channel corner extrusion; for the alloy The rod is subjected to hot extrusion processing, the extrusion temperature is 300°C, the extrusion speed is 1.2m / min, and the extrusion ratio is 35. After extrusion, it is water quenched to obtain an aging-free high-strength aluminum alloy based on large deformation homogenization.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com