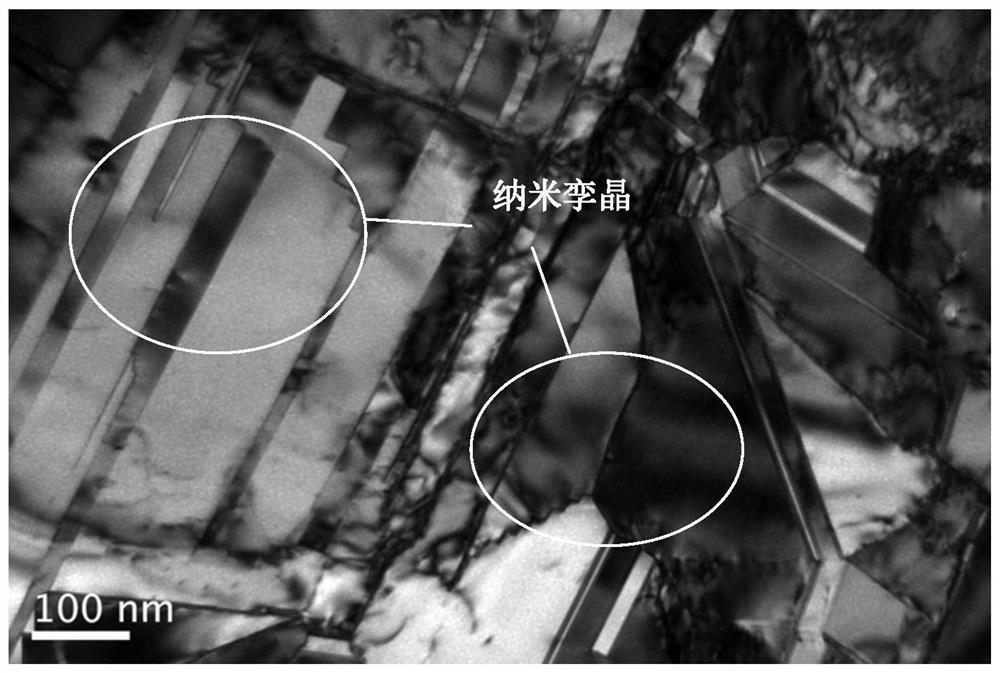

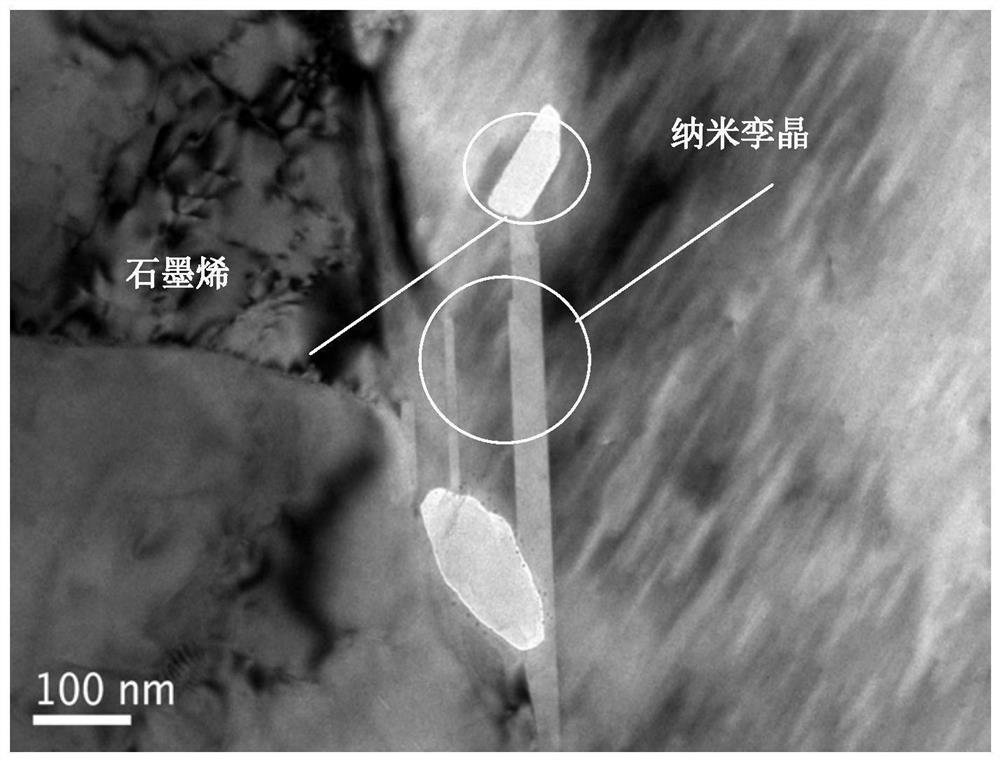

A kind of graphene/nano-twin composite material with controllable structure and preparation method thereof

A composite material and nano-twin technology, applied in the direction of electrolytic coatings, coatings, etc., can solve the problem that the comprehensive performance of materials has not been greatly improved, and achieve the effect of small grains, uniform grains, and regular shapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The composition ratio of the metal-based composite deposition solution is: 0.8M copper sulfate pentahydrate, 0.05M graphene, 0.2M H 2 SO 4 , sodium polydithiodipropylsulfonate 0.0003M, ethylthiourea 0.0008M, copper chloride 0.0002M; electrodeposition process parameters are: current density 90mA / cm 2 , the temperature is 50°C, the deposition time is 30min; the magnetic field strength is 0.1T, and the angle between the magnetic field direction and the pole plate is 5°. The surface color of the composite material prepared under this condition is dark, the compactness is average, there are a small amount of nano-twins in the microstructure of the composite material, the volume ratio of the nano-twins is 5%, the average thickness of the nano-twinned layer is 150nm, and the grain The average size is 485 nm, and the volume ratio of graphene is 7%.

Embodiment 2

[0023] The composition ratio of the metal-based composite deposition solution is: 0.8M copper sulfate pentahydrate, 0.05M graphene, 0.2M H 2 SO 4 , sodium polydithiodipropylsulfonate 0.0004M, ethylthiourea 0.0007M, copper chloride 0.0003M; electrodeposition process parameters are: current density 90mA / cm 2 , the temperature is 50°C, the deposition time is 30min; the magnetic field strength is 0.3T, and the angle between the magnetic field direction and the pole plate is 20°. The composite material prepared under this condition has a smooth surface and good compactness. The microstructure of the composite material has a certain amount of nano-twins, the volume ratio of the nano-twins is 18%, the average thickness of the nano-twinned layer is 120nm, the grain The average size is 440nm, and the volume ratio of graphene is 5%.

Embodiment 3

[0025] The composition ratio of the metal-based composite deposition solution is: 0.8M copper sulfate pentahydrate, 0.05M graphene, 0.2M H 2 SO 4 , sodium polydithiodipropylsulfonate 0.0005M, ethylthiourea 0.0006M, copper chloride 0.0004M; electrodeposition process parameters are: current density 90mA / cm 2 , the temperature is 50°C, the deposition time is 30min; the magnetic field strength is 0.3T, and the angle between the magnetic field direction and the pole plate is 20°. The composite material prepared under this condition has a smooth surface and good compactness. The microstructure of the composite material has a certain amount of nano-twins, the volume ratio of nano-twins is 22%, the average thickness of the nano-twin layer is 80nm, and The average size is 360nm, and the volume ratio of graphene is 10%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com