Kelp microcrystalline cellulose and preparation method thereof as well as application of prepared kelp microcrystalline cellulose

A technology of microcrystalline cellulose and low-temperature cellulase, which is applied in the fields of application, food preparation, food science, etc., can solve the problems of preparing microcrystalline cellulose without kelp dregs, achieve shortened enzymatic hydrolysis time, low production cost, The effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

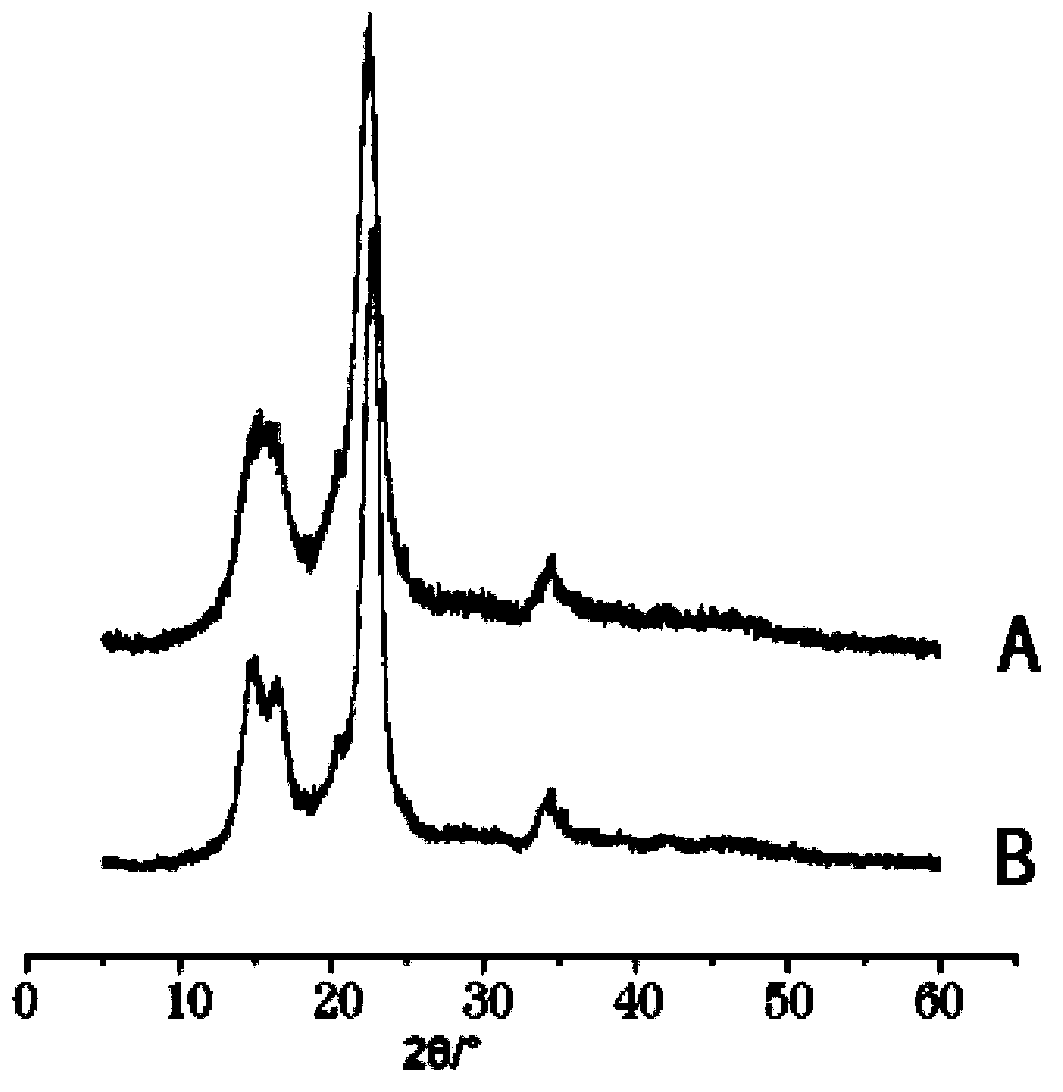

[0046] A kind of kelp microcrystalline cellulose, the kelp microcrystalline cellulose is prepared from the discarded kelp slag after kelp extraction, the appearance of the kelp microcrystalline cellulose is powdery, and its color is white. The fiber content of kelp microcrystalline cellulose is 98.18%, the degree of polymerization is 138.3±6.4, the whiteness is 89.1%, the water content is 2.25%, the water holding capacity is 1800%, and the swelling force is 25ml / g.

Embodiment 2

[0048] A kelp microcrystalline cellulose, the kelp microcrystalline cellulose is prepared from the discarded kelp slag after the kelp is extracted, and is prepared by double enzymatic hydrolysis with two different low-temperature cellulases, and the kelp microcrystalline cellulose The appearance of the kelp is powdery, and the color is white. The fiber content of the kelp microcrystalline cellulose is 98.39%, the degree of polymerization is 138.3±3.8, the whiteness is 89.2%, the water content is 2.24%, the water holding capacity is 2000%, and the expansion force At 30ml / g. The two different low-temperature cellulases are low-temperature cellulase obtained by culturing Pseudoalteromonas sp NJ64 and Pseudoalteromonas sp 545, which are screened by Antarctic bacteria, respectively.

Embodiment 3

[0050] The method for kelp microcrystalline cellulose, comprises the following steps:

[0051] (1) Flocculation collection: add a calcium chloride solution with a concentration of 12wt% to the kelp slag glue solution after the gel extraction, leave it to flocculate after stirring, and collect the flocs. The amount of calcium chloride added in the calcium chloride solution is It is 3wt% of kelp slag glue weight.

[0052] (2) Decalcification by adding acid: Put the above flocs into the reaction tank, add acid solution according to 2.5wt% of the weight of kelp slag glue, add water to dilute, heat to 35°C, stir for 8 hours to decalcify, and make the above The flocs are fully soaked.

[0053] (3) Alkali treatment: add sodium carbonate solution to the flocs after decalcification, according to the amount of sodium carbonate added in the sodium carbonate solution is 2wt% of the weight of the kelp residue glue, and add water until the flocs are adsorbed and saturated, Soak and stir a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com