Long-life low-platinum bimetallic catalyst for methylcyclohexane and preparation method of long-life low-platinum bimetallic catalyst

A bimetallic catalyst and methylcyclohexane technology are applied in the field of long-life and low-platinum bimetallic catalysts and their preparation, which can solve the problems of rapid catalyst deactivation, high precious metal content, short life and the like, and achieve low cost and precious metal content. Low, life-extending effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

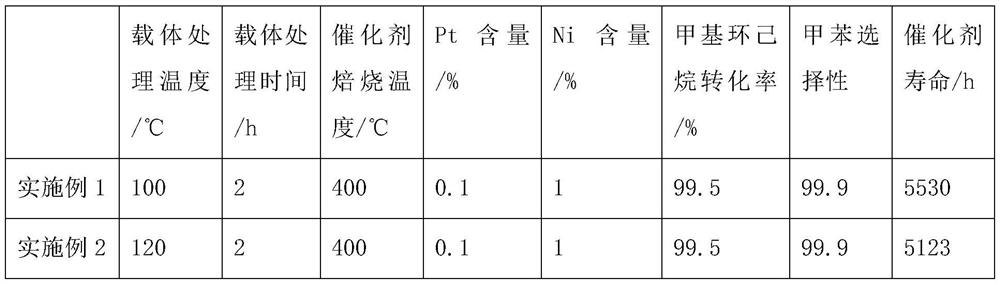

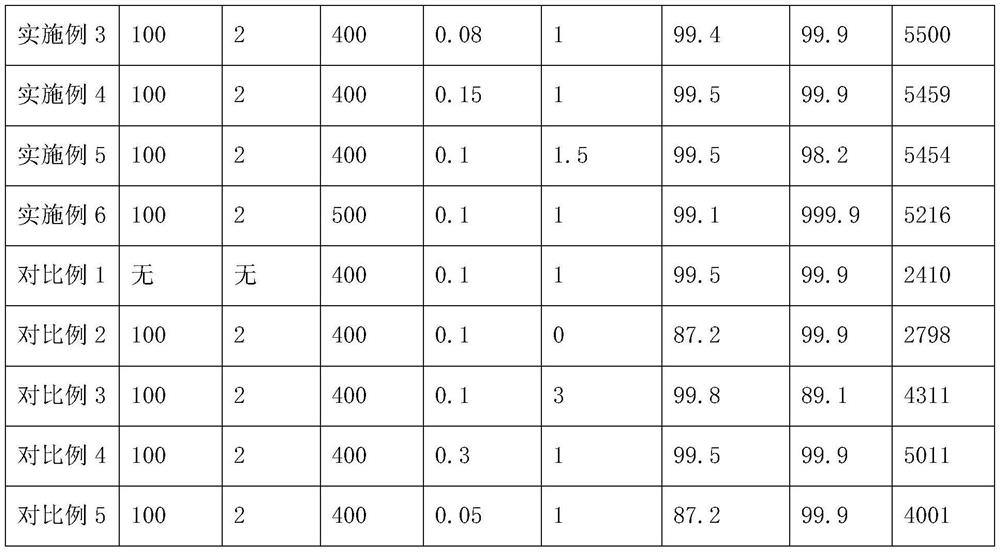

Embodiment 1

[0031] A preparation method for a long-life low platinum bimetallic catalyst for methylcyclohexane, comprising the steps,

[0032] (1) Add γ-Al 2 o 3 Add to tube furnace, pass H into the tube furnace 2 , heated up to 100°C and purged for 2 hours to obtain activated γ-Al 2 o 3 carrier;

[0033] (2) A certain amount of chloroplatinic acid and nickel nitrate (by Pt loading 0.1%, Ni loading 1%) are dissolved in a certain amount of water, the mass fraction of the total mass of the compound containing Pt and Ni in the solution is 5% , adjust its pH value to 5 with citric acid;

[0034] (3) The obtained activated γ-Al 2 o 3 The carrier was added to the above aqueous solution, mixed evenly, and aged at room temperature for 12 hours. The product was dried in an air atmosphere at 120° C. for 12 hours, crushed and then pressed into tablets. Calcined in air atmosphere at 400°C for 4 hours to prepare the catalyst.

Embodiment 2

[0036] A preparation method for a long-life low platinum bimetallic catalyst for methylcyclohexane, comprising the steps,

[0037] (1) Add γ-Al 2 o 3 Add to tube furnace, pass H into the tube furnace 2 , heated to 120°C and purged for 2 hours to obtain activated γ-Al 2 o 3 carrier;

[0038] (2) A certain amount of chloroplatinic acid and nickel nitrate (by Pt loading 0.1%, Ni loading 1%) are dissolved in a certain amount of water, the mass fraction of the total mass of the compound containing Pt and Ni in the solution is 5% , adjust its pH value to 5 with citric acid;

[0039] (3) The obtained activated γ-Al 2 o 3 The carrier was added to the above aqueous solution, mixed evenly, and aged at room temperature for 12 hours. The product was dried in an air atmosphere at 120° C. for 12 hours, crushed and then pressed into tablets. Calcined in air atmosphere at 400°C for 4 hours to prepare the catalyst.

Embodiment 3

[0041] A preparation method for a long-life low platinum bimetallic catalyst for methylcyclohexane, comprising the steps,

[0042] (1) Add γ-Al 2 o 3 Add to tube furnace, pass H into the tube furnace 2 , heated up to 100°C and purged for 2 hours to obtain activated γ-Al 2 o 3 carrier;

[0043] (2) A certain amount of chloroplatinic acid and nickel nitrate (by Pt loading 0.08%, Ni loading 1%) are dissolved in a certain amount of water, the mass fraction of the total mass of the compound containing Pt and Ni in the solution is 5% , adjust its pH value to 5 with citric acid;

[0044] (3) The obtained activated γ-Al 2 o 3 The carrier was added to the above aqueous solution, mixed evenly, and aged at room temperature for 12 hours. The product was dried in an air atmosphere at 120° C. for 12 hours, crushed and then pressed into tablets. Calcined in air atmosphere at 400°C for 4 hours to prepare the catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com