Horizontal desmear and copper removal line and method for desmear and copper removal

An assembly line and horizontal technology, applied in the direction of metal processing equipment, grinding machines, manufacturing tools, etc., can solve the problem of increasing the length of the desmearing and copperizing line, not suitable for installation and use in small factories, the efficiency and quality of desmearing and copperizing treatment Not advanced question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

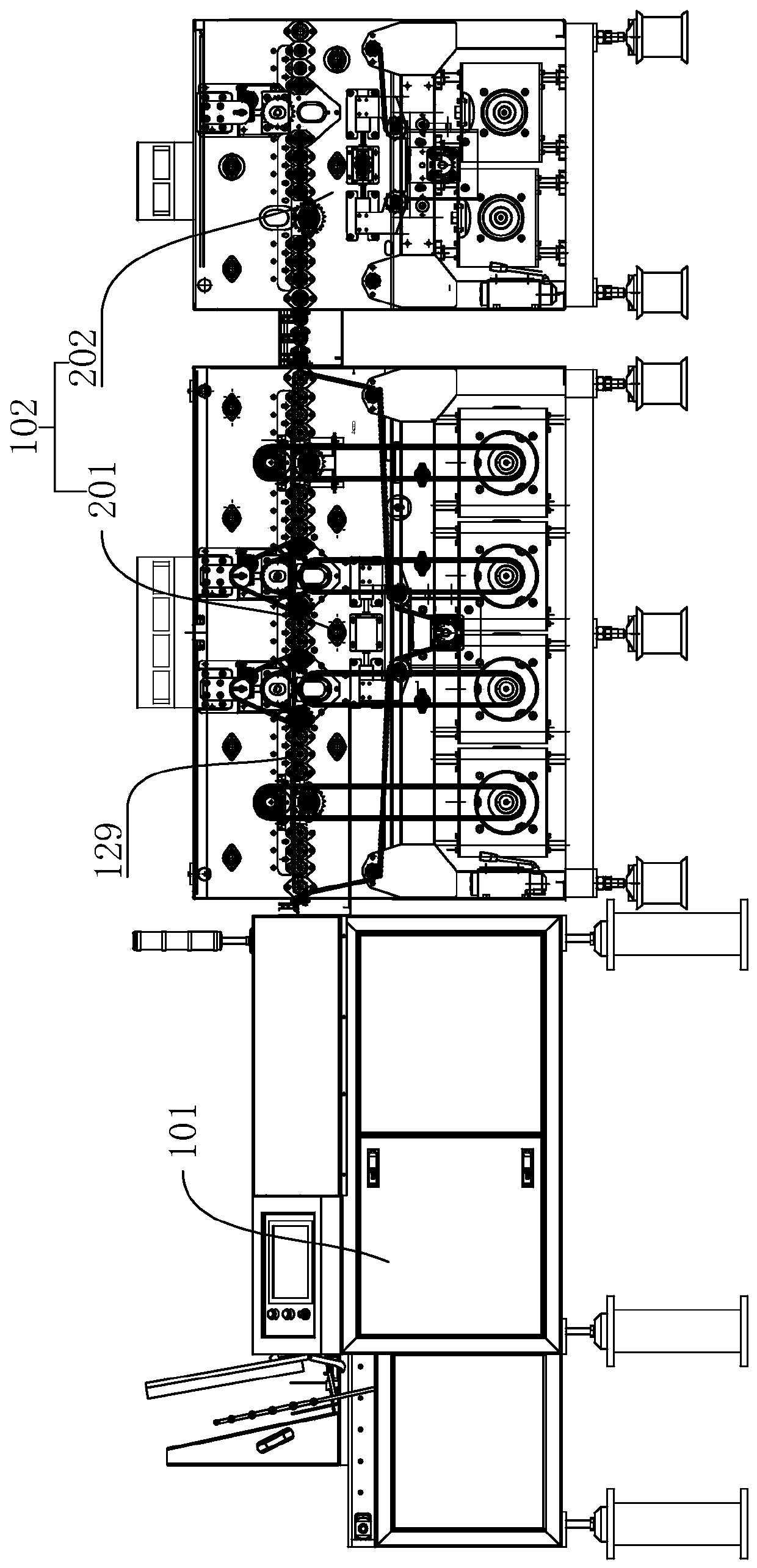

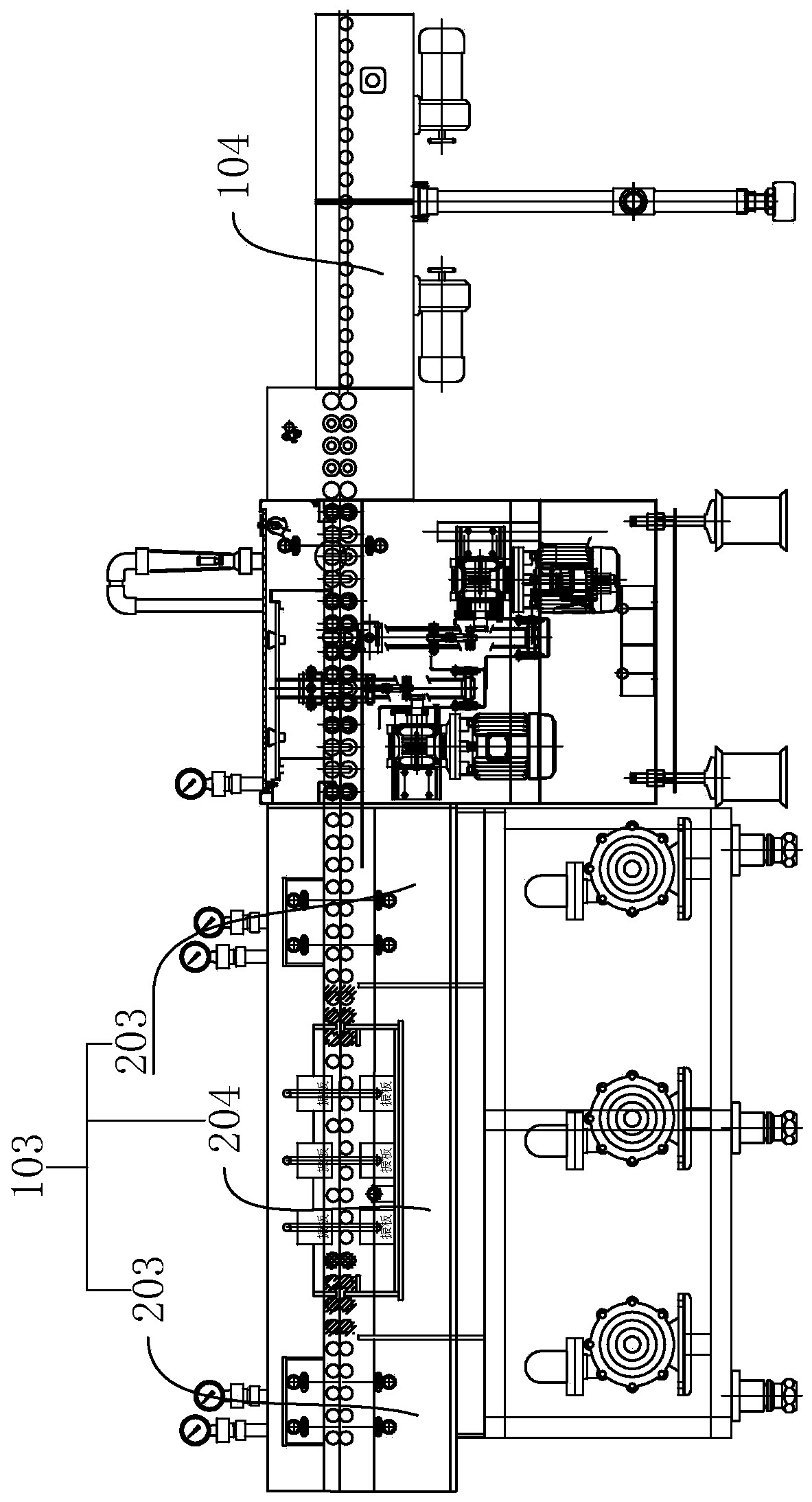

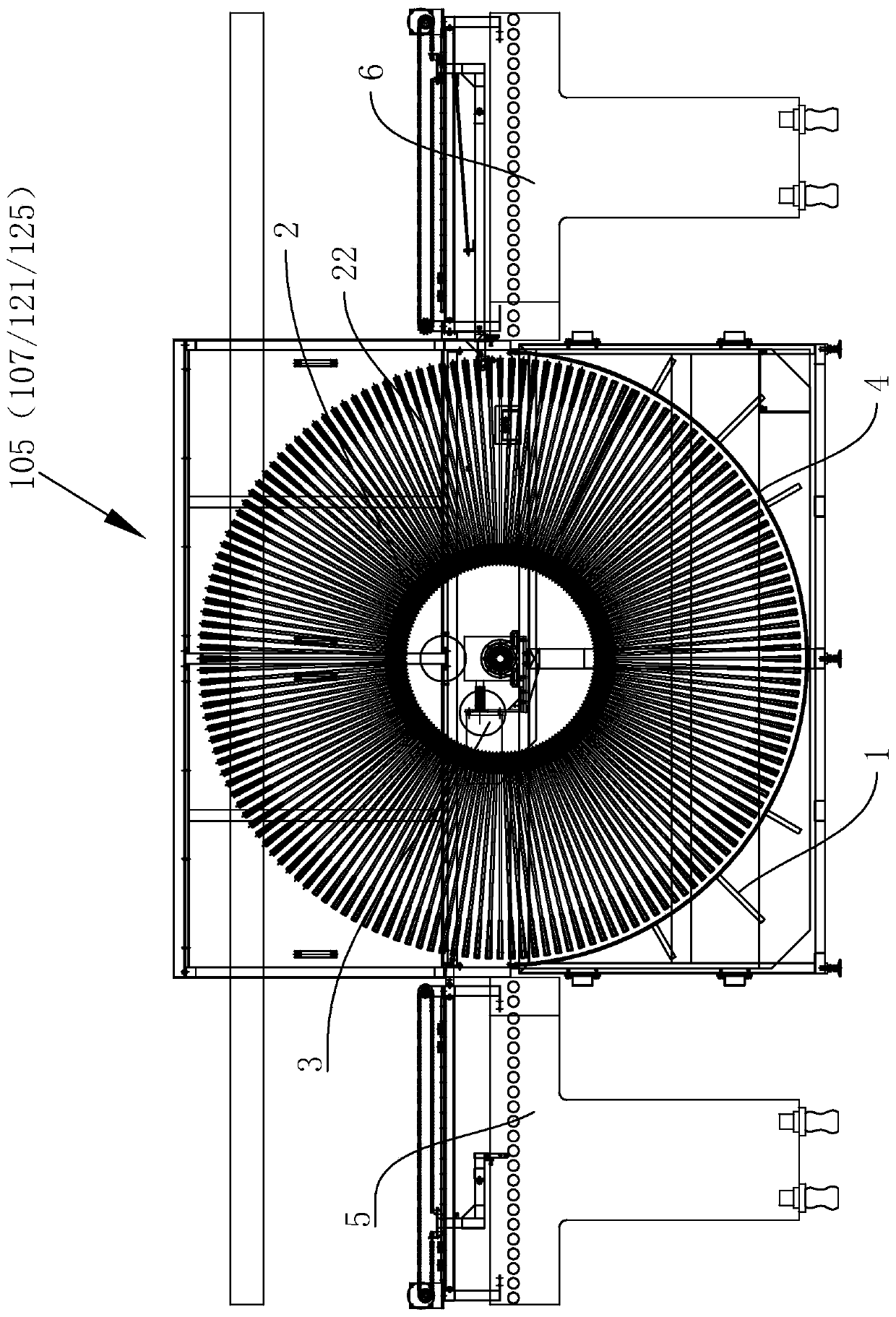

[0070] refer to figure 1 , is a horizontal slag removal and copper melting line disclosed in the present invention, including: an automatic board placing machine 101 and a board grinding unit 102 . The automatic plate placing machine 101 is used to input the stacked plates horizontally one by one, and the plate grinding unit 102 is used to remove the oxide on the surface of the plate and roughen the surface of the plate. The automatic plate placing machine 101 can directly purchase mature equipment (such as The announcement number is a kind of automatic plate-laying device disclosed by the Chinese utility model CN204433783U for the horizontal production line of PCB board); the plate grinding unit 102 includes sequentially arranged: rough grinding plate machine 201 and fine grinding plate machine 202, rough grinding plate Machine 201 and fine grinding machine 202 can directly buy mature equipment from the market (a kind of grinding machine for polishing circuit boards disclosed...

Embodiment 2

[0101] The present invention also discloses a method for removing slag and copper, based on the horizontal desmear and copper removal line described in Embodiment 1, the method for removing scum and copper includes the following steps in sequence: automatic plate placement, plate grinding treatment, the first water washing treatment, the first artificial appearance inspection, bulky surface treatment, the second water washing treatment, the desmear surface treatment, the third water washing treatment, pre-neutralization treatment, the fourth water washing treatment, and then Neutralization treatment, the fifth washing treatment, the first drying treatment, the second manual appearance inspection, hot water knife immersion treatment, hole-making treatment, sixth washing treatment, micro-etching treatment, seventh washing treatment , pre-soaking treatment, activation treatment, eighth water washing treatment, reduction treatment, ninth water washing treatment, copper treatment, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com