Preparation method and application of lead tungstate/cadmium sulfide composite visible-light-driven photocatalyst

A technology of cadmium sulfide and lead tungstate, which is applied in the field of preparation of lead tungstate/cadmium sulfide composite visible light catalyst, can solve the problems of reduced photocatalytic performance, easy recombination of electrons and holes, etc., and achieves low cost and high charge separation efficiency. , the preparation method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

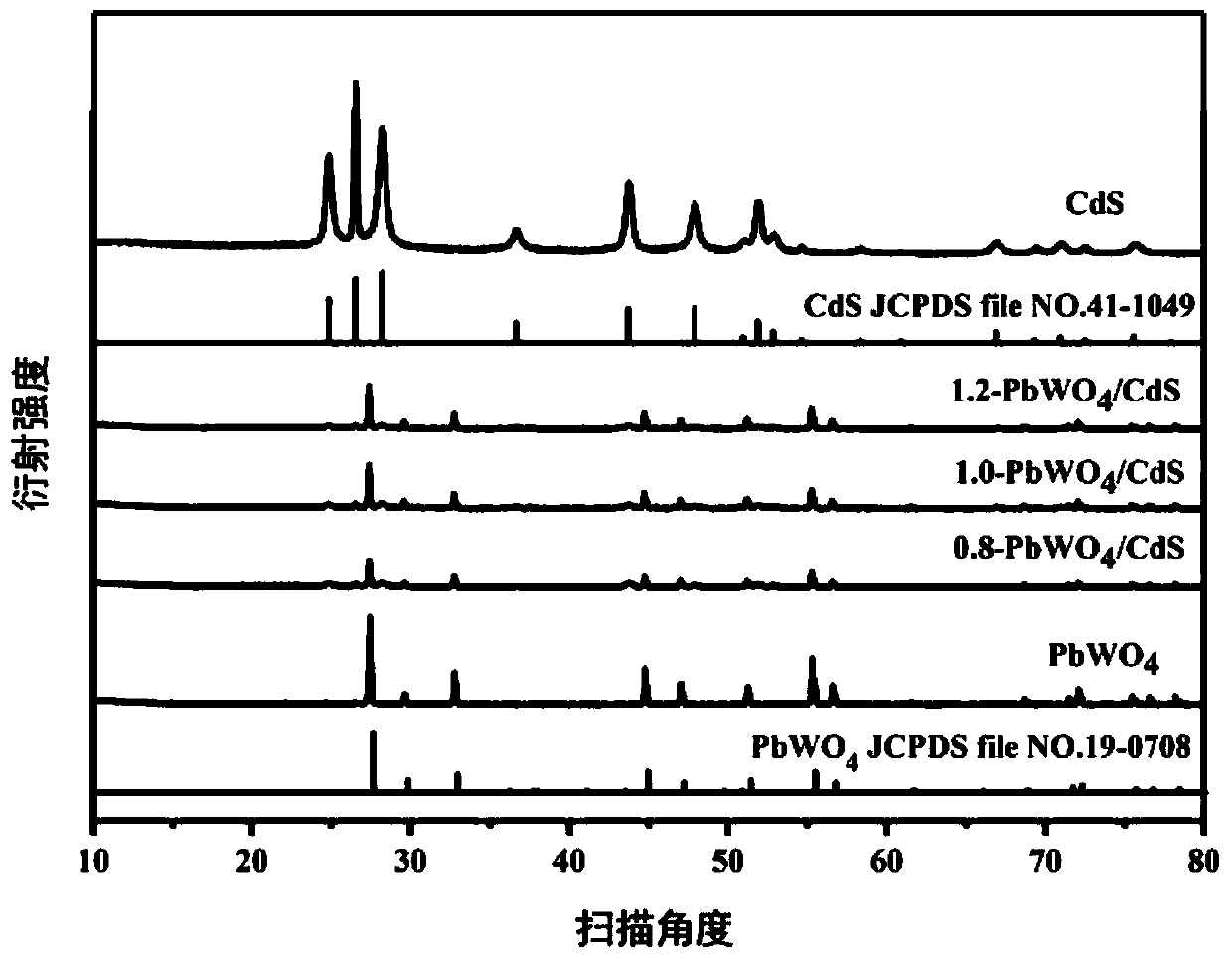

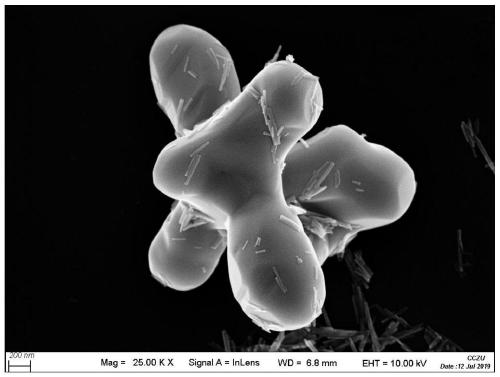

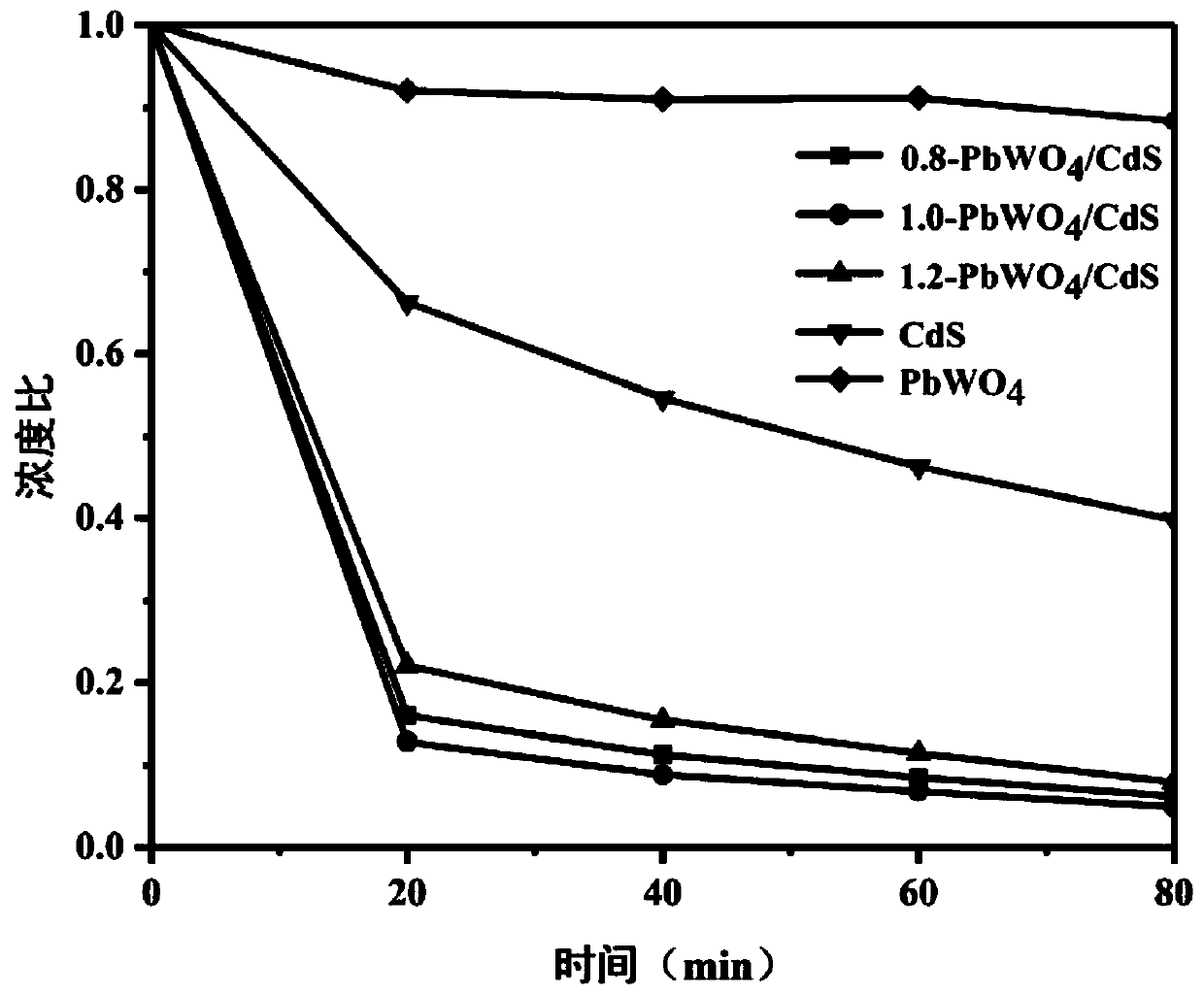

[0027] (1) Add 4.66g of cadmium nitrate and 3.45g of thiourea to 70ml of ethylenediamine at the same time, stir ultrasonically for 30min, then put the mixture into a 100ml reactor, and conduct a hydrothermal reaction at 160°C for 24h. Cool naturally at room temperature, wash the precipitate three times alternately with deionized water and ethanol, and obtain an orange cadmium sulfide sample.

[0028] (2) Add 0.189g of lead acetate and 0.165g of sodium tungstate into 100ml of deionized water, and stir magnetically for 2 hours to obtain a uniform suspension. Then, the obtained suspension was transferred into a 100ml reactor, and subjected to hydrothermal reaction at 180°C for 24h. Finally, the obtained product was centrifuged and washed 3 times with deionized water and ethanol, and dried at 100 °C for 2 hours to obtain a lead tungstate sample.

[0029] (3) Preparation of lead tungstate / cadmium sulfide composite photocatalyst: ultrasonicate lead tungstate and cadmium sulfide in ...

Embodiment 2

[0031] (1) Preparation of cadmium sulfide: Add 4.66g of cadmium nitrate and 3.45g of thiourea to 70ml of ethylenediamine at the same time, stir ultrasonically for 50min, then put the mixture into a 100ml reactor, and conduct a hydrothermal reaction at 170°C for 30h. Cool naturally at room temperature, wash the precipitate five times alternately with deionized water and ethanol to obtain an orange sample, and collect a powder sample.

[0032] (2) Preparation of lead tungstate: Add 0.189g of lead acetate and 0.165g of sodium tungstate into 100ml of deionized water, and stir magnetically for 2 hours to obtain a uniform suspension. Then, the obtained suspension was transferred into a 100ml reactor, and subjected to hydrothermal reaction at 180°C for 24h. Finally, the resulting product was centrifuged and washed 5 times with deionized water and ethanol, and dried at 100 °C for 2 h.

[0033] (3) Preparation of lead tungstate / cadmium sulfide composite photocatalyst: ultrasonicate le...

Embodiment 3

[0036] (1) Preparation of cadmium sulfide: Add 4.66g of cadmium nitrate and 3.45g of thiourea to 70ml of ethylenediamine at the same time, stir ultrasonically for 50min, then put the mixture into a 100ml reactor, and conduct a hydrothermal reaction at 170°C for 30h. Cool naturally at room temperature, wash the precipitate five times alternately with deionized water and ethanol to obtain an orange sample, and collect a powder sample.

[0037] (2) Preparation of lead tungstate: Add 0.189g of lead acetate and 0.165g of sodium tungstate into 100ml of deionized water, and stir magnetically for 2 hours to obtain a uniform suspension. Then, the obtained suspension was transferred into a 100ml reactor, and subjected to hydrothermal reaction at 170°C for 30h. Finally, the resulting product was centrifuged and washed 5 times with deionized water and ethanol, and dried at 100 °C for 2 h.

[0038] (3) Preparation of lead tungstate / cadmium sulfide composite photocatalyst: ultrasonicate le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com