Preparation method of graphite carbon coated iron-nitrogen-carbon solid-phase Fenton catalyst and its application

A catalyst, graphitic carbon technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problem of decomposing action to be studied, high cost, and achieve the promotion of decomposing action, excellent performance, synthesis simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

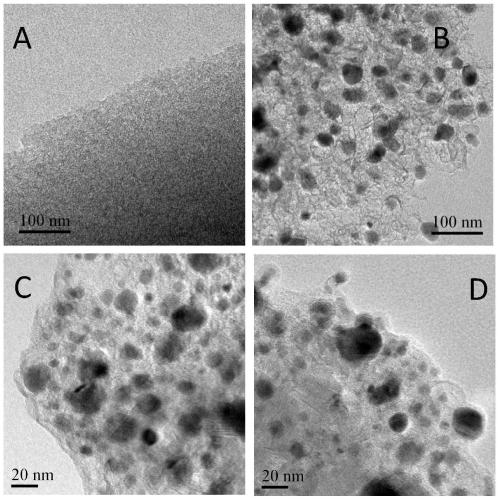

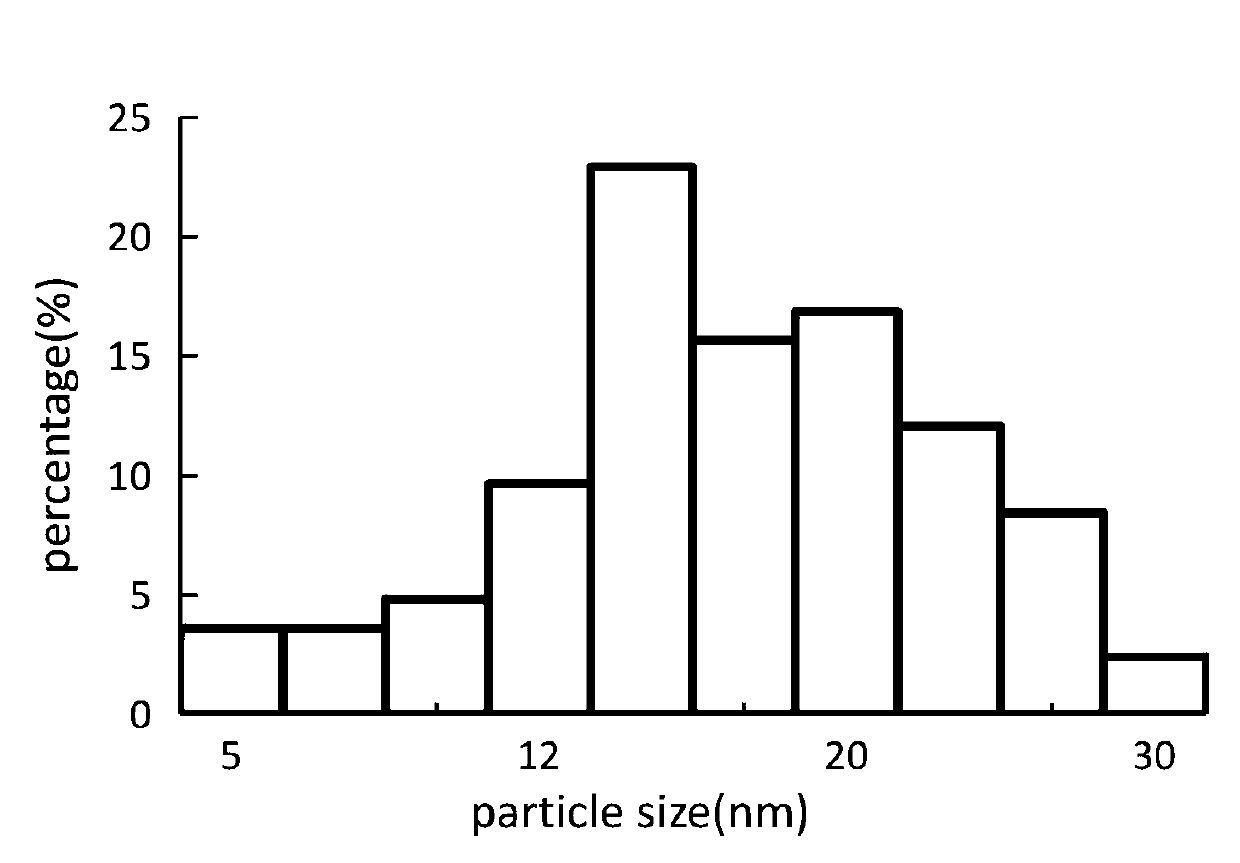

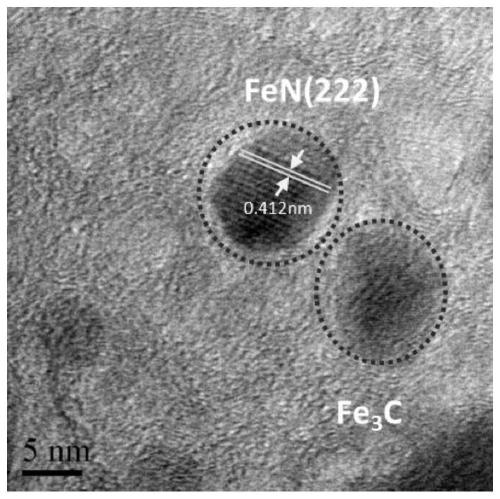

[0044] A graphite carbon-wrapped iron-nitrogen-carbon solid-phase Fenton catalyst, the preparation method of which is as follows:

[0045] 1) Mix 3g of glucose and 8g of urea (the molar ratio of carbon source to nitrogen source is 1:8), heat and melt at 150°C until clarified, then add 3.03g of ferric nitrate nonahydrate and stir until completely dissolved, transfer to Dry in an oven at 180°C for 12h, and then calcined at 750°C for 2h under the protection of nitrogen atmosphere to obtain a graphite carbon-wrapped iron-nitrogen-carbon solid-phase Fenton catalyst. The mass fraction of Fe in the synthesized catalyst is 35%, labeled as FeNC@C-35.

Embodiment 2

[0047] A graphite carbon-wrapped iron-nitrogen-carbon solid-phase Fenton catalyst, the preparation method of which is as follows:

[0048] Mix 3g of glucose and 5g of urea (the molar ratio of carbon source to nitrogen source is 1:5), heat and melt at 150°C until clarified, then add 1.73g of ferric nitrate nonahydrate and stir until completely dissolved, then transfer to 180°C Drying in an oven for 12 hours, followed by calcining at 750°C for 2 hours under the protection of a nitrogen atmosphere to obtain a graphite carbon-wrapped iron-nitrogen-carbon solid-phase Fenton catalyst, the mass fraction of Fe in the synthesized catalyst is 20% , labeled as FeNC@C-20.

Embodiment 3

[0050] A graphite carbon-wrapped iron-nitrogen-carbon solid-phase Fenton catalyst, the preparation method of which is as follows:

[0051] Mix 3g of glucose with 11g of urea (the molar ratio of carbon source to nitrogen source is 1:11), heat and melt at 150°C until clarified, then add 4.32g of ferric nitrate nonahydrate and stir until completely dissolved, then transfer to 180 ℃ in an oven for 24 hours, and then under the protection of nitrogen atmosphere, calcined at 750 ℃ for 2 hours to obtain the iron-nitrogen-carbon solid-phase Fenton catalyst wrapped in graphite carbon. The mass fraction of Fe element in the synthesized catalyst is 50 %, marked as FeNC@C-50.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com