Preparation method and application of ceramic membrane diffusion layer prepared by using yttrium-stabilized zirconia material

A yttrium-stabilized zirconia and ceramic membrane technology, applied in the field of passive sampling of gradient diffusion films, can solve the problems of large mass transfer resistance, influence on the accuracy of measurement results, easy damage, etc., achieve high mechanical strength, overcome long-term exposure to be degraded by microorganisms Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

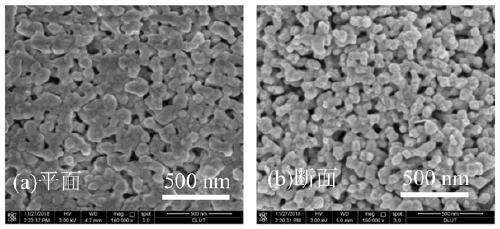

[0039] The preparation process of the ceramic membrane diffusion layer is as follows: First, inject absolute ethanol into the yttrium-stabilized zirconia powder, add zirconia ball mills, and then perform a high-speed ball mill in a horizontal mixer for 12 hours to disperse the powder evenly, and then dry the anhydrous ethanol in an oven. Dried and ground. Take 5g of pretreated zirconia powder, add 1mL of polyvinyl alcohol solution with a mass fraction of 5% as a binder, grind to make it fully mixed, accurately weigh 1.50g, and move it to a tableting mold with an inner diameter of 25mm. The tablet press presses it into a tablet sample, and slowly pressurizes to 10MPa during the pressing process, and slowly releases the pressure after maintaining for 1min. Afterwards, the prepared sample pieces were placed in a box-type high-temperature sintering furnace and calcined at 700 and 1050 °C for 2 h, respectively. The sample sintering procedure is as follows: firstly, the temperature...

Embodiment 2

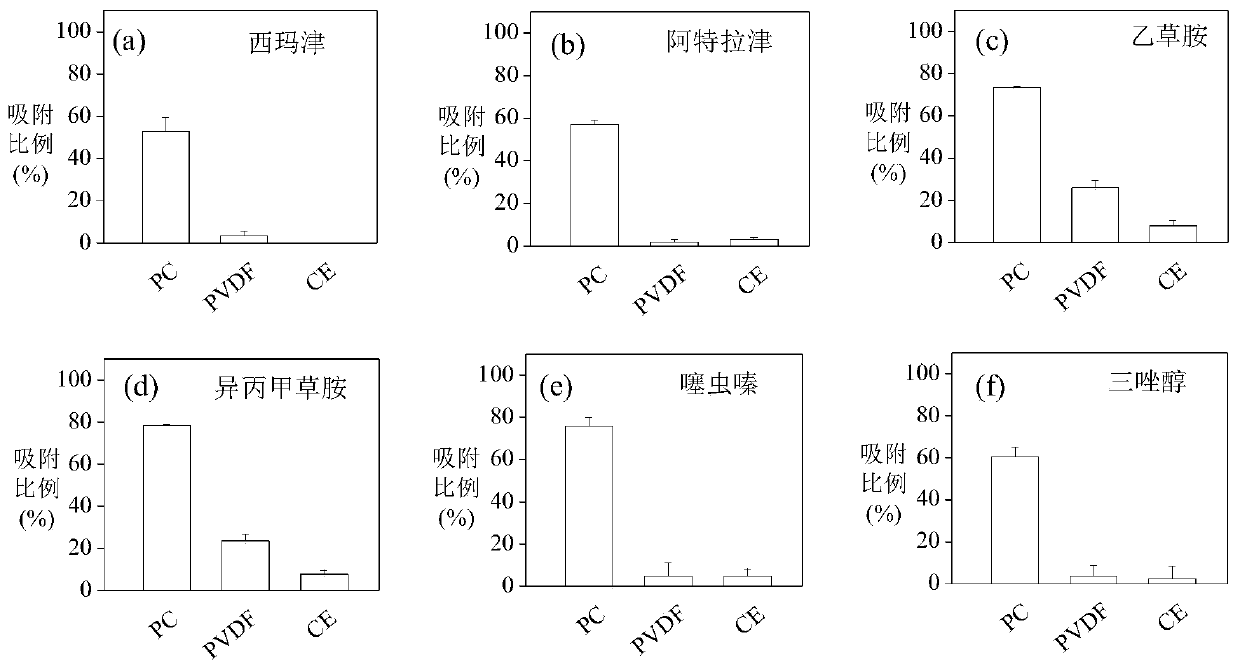

[0041]Ceramic membrane diffusion layer prepared by the present invention, polyvinylidene fluoride filter membrane and polycarbonate filter membrane are submerged in 10mL containing 20 μ g / L 6 kinds of organic pollutants (simazine, atrazine, acetochlor, metolachlor, thiamethoxam, triadiazole) solution, placed in a shaking incubator for 12 hours of vigorous shaking adsorption, using ultra-high performance liquid chromatography tandem mass spectrometry to measure the concentration changes of organic pollutants in the solution before and after adsorption. The adsorption of six kinds of organic pollutants by the ceramic membrane diffusion layer and two organic polymer filter membranes is as follows: figure 2 shown. The results showed that the diffusion layer of the ceramic membrane had no obvious adsorption on the 6 kinds of organic pollutants, while the adsorption ratio of the polycarbonate filter membrane to all pollutants in the solution was higher than 50%, and the polyvinylid...

Embodiment 3

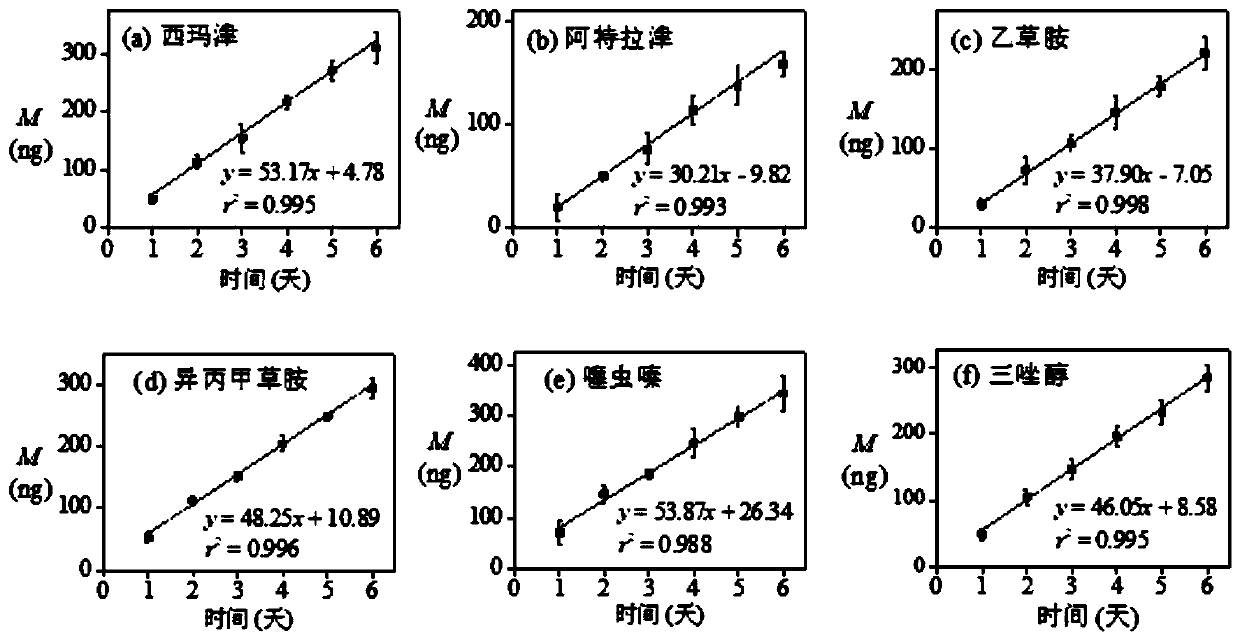

[0043] A DGT sampler equipped with a ceramic membrane diffusion layer was exposed to 10 L of a solution containing 10 μg / L of organic pollutants. During the exposure period, a mechanical stirrer was used to stir the water rapidly to keep the water in a turbulent state. On the first to sixth days of sampling, 3 DGTs were taken out and removed. Determination of the adsorption amount in the adsorption layer, the extraction quality of the organic pollutants in the ceramic membrane diffusion layer DGT at different sampling times is as follows: image 3 shown. The results showed that the ceramic membrane diffusion layer DGT showed a linear increase in the amount of organic pollutants extracted during the 6-day sampling period, which proved that the ceramic membrane diffusion layer can limit the diffusion of organic pollutants and meet the requirements of DGT. Conditions apply.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com