Preparation of p-hydroxybenzaldehyde enrichment reagent and products and applications

A p-hydroxybenzaldehyde and enrichment technology, applied in the polymer field, can solve the problems of narrow application range, few mobile phase types, complicated separation of large-scale precision instruments, etc., and achieves the effects of broad application prospects, simple operation and short time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

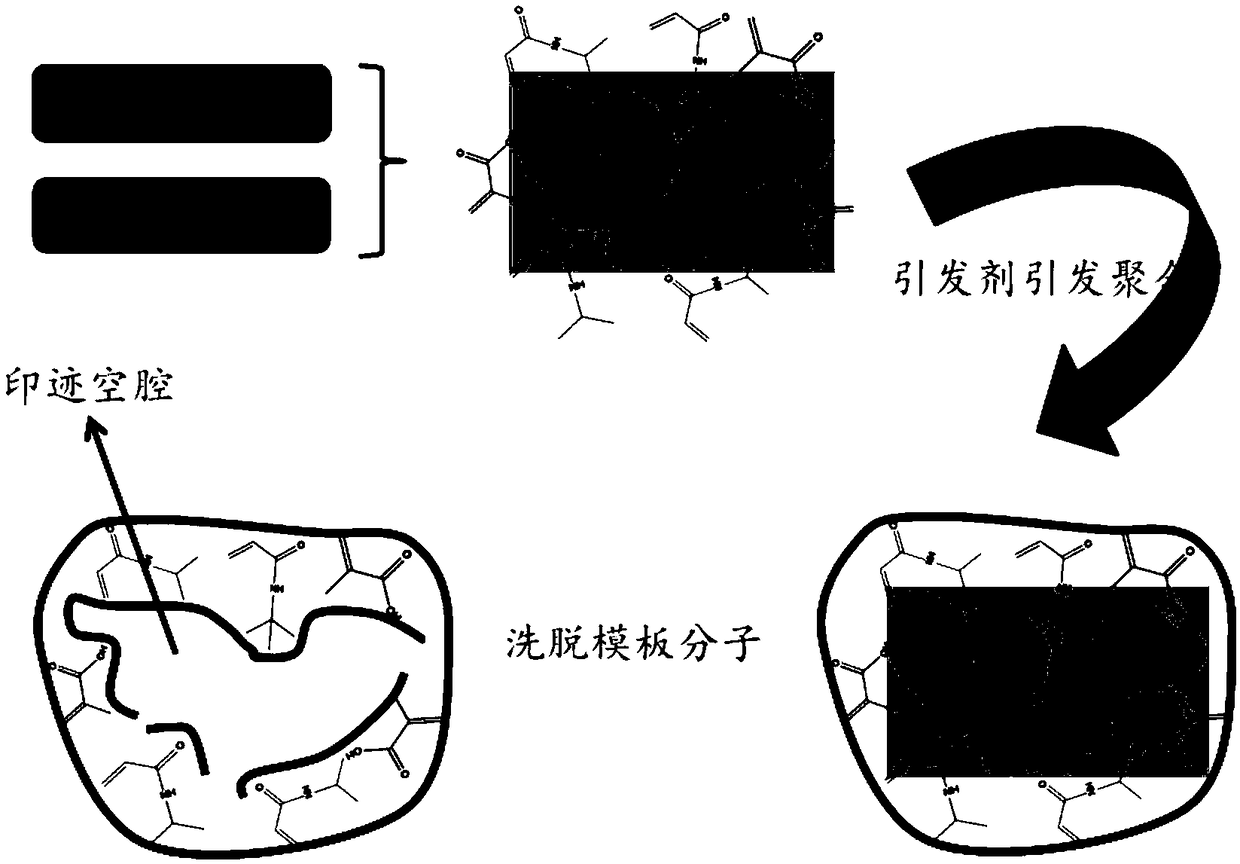

[0031] According to the first aspect of the present invention, in a preferred embodiment, the preparation method of p-Hydroxybenzaldehyde enrichment reagent comprises the following steps:

[0032] S1: Accurately weigh acrylic acid (0.2-0.3mmol), N-isopropylacrylamide, N,N-dimethylbisacrylamide, ultrasonically dissolve in 80mL water; then add N-tert-butylacrylamide in anhydrous Ethanol (1mL) solution, ultrasonic degassing for 10min;

[0033] S2: After adjusting the pH=6.0, adding p-hydroxybenzaldehyde as a template molecule;

[0034] Among them, the template molecules are added in the following molar ratios:

[0035] MIP-1: (acrylic acid: template molecule = 1:2)

[0036] MIP-2: (acrylic acid: template molecule = 1:4)

[0037] MIP-3: (acrylic acid: template molecule = 1:8)

[0038] MIP-4: (acrylic acid: template molecule = 1:16)

[0039] S3: Slowly add the aqueous solution of the initiator (ammonium persulfate, sodium bisulfite and sodium lauryl sulfate) dropwise, and poly...

Embodiment 1

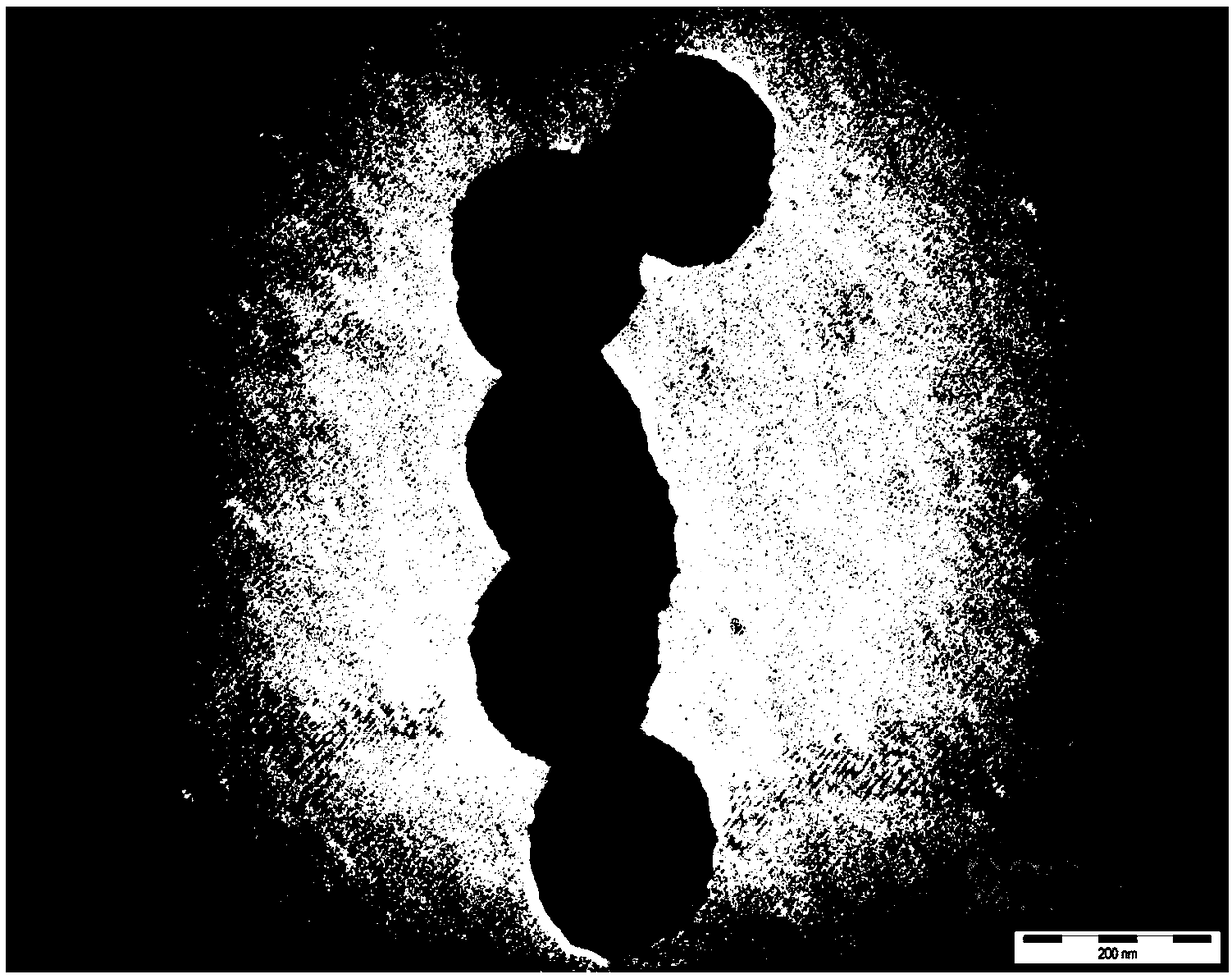

[0048] Accurately weigh acrylic acid (0.2mmol), N-isopropylacrylamide (0.4mmol), N,N-dimethylbisacrylamide (2mmol) dissolved in 80mL distilled water, N-tert-butylacrylamide (0.2mmol) Dissolve in 1 mL of absolute ethanol, sonicate for 10 min; then, adjust pH=6.0 with NaOH, add 1.6 mmol template molecule (p-hydroxybenzaldehyde) (dissolved in distilled water), shake at 70 rpm at constant temperature (35°C) for 4 hours; then, slowly The aqueous solution of the initiator (ammonium persulfate (60.0mg), sodium bisulfite (20.0mg), sodium lauryl sulfate (40.0mg) dissolved in 20mL of distilled water) was added dropwise, and the polymerization reaction was carried out at 35°C for 24h;

[0049] After the reaction is complete, use ethanol-chloroform as the extractant, and use a Soxhlet extractor to reflux overnight to elute the template molecule (p-hydroxybenzaldehyde) to obtain a crude molecularly imprinted polymer;

[0050] The molecularly imprinted polymer crude product is dialyzed with...

Embodiment 2

[0054] ①Preparation of enrichment reagent solution (1mg / mL)

[0055] Accurately weigh 5.0 mg p-hydroxybenzaldehyde enrichment reagent MIP-3 and ultrasonically dissolve it in 5.0 mL of distilled water to prepare a 1 mg / mL enrichment reagent solution;

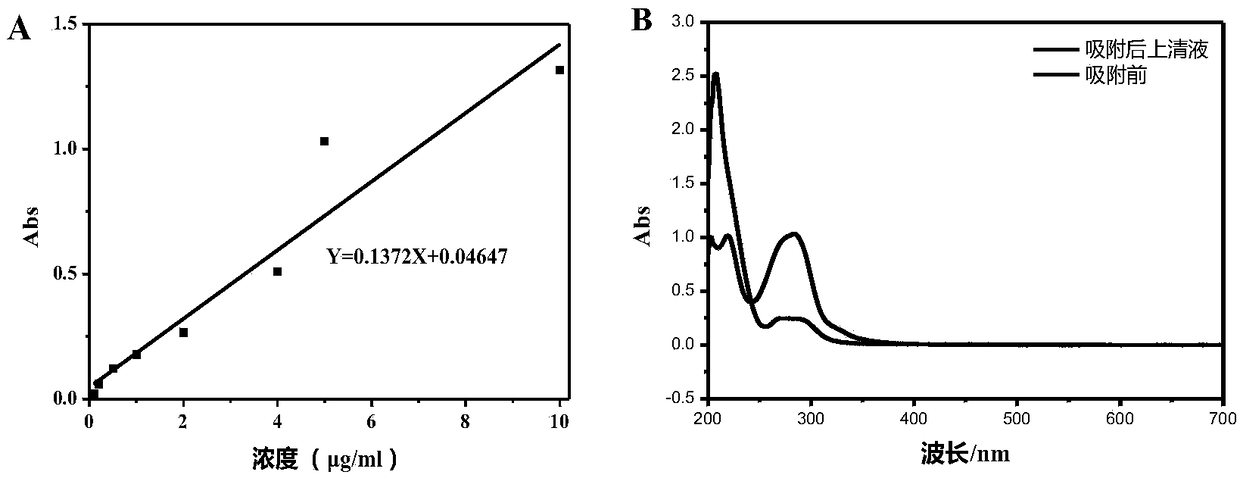

[0056] ②Determination of p-hydroxybenzaldehyde concentration-UV absorbance standard curve (0.1, 0.2, 0.5, 1.0, 2.0, 4.0, 5.0, 10.0μg / mL)

[0057] Purchase or prepare a standard solution of 100 μg / mL p-hydroxybenzaldehyde by yourself: Accurately weigh 2.0 mg of p-hydroxybenzaldehyde and dissolve it in 20.0 mL of absolute ethanol.

[0058] Preparation of 10μg / ml p-hydroxybenzaldehyde solution: 1ml 100μg / ml p-hydroxybenzaldehyde solution + 9ml absolute ethanol; preparation of 5μg / ml p-hydroxybenzaldehyde solution: 5ml 10μg / ml p-hydroxybenzaldehyde solution + 5ml anhydrous Ethanol; preparation of 4μg / ml p-hydroxybenzaldehyde solution: 2ml 10μg / ml p-hydroxybenzaldehyde solution + 3ml absolute ethanol; preparation of 2μg / ml p-hydroxyb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| UV absorbance | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| UV absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com