Direct methanol fuel cell membrane electrode and preparation and application

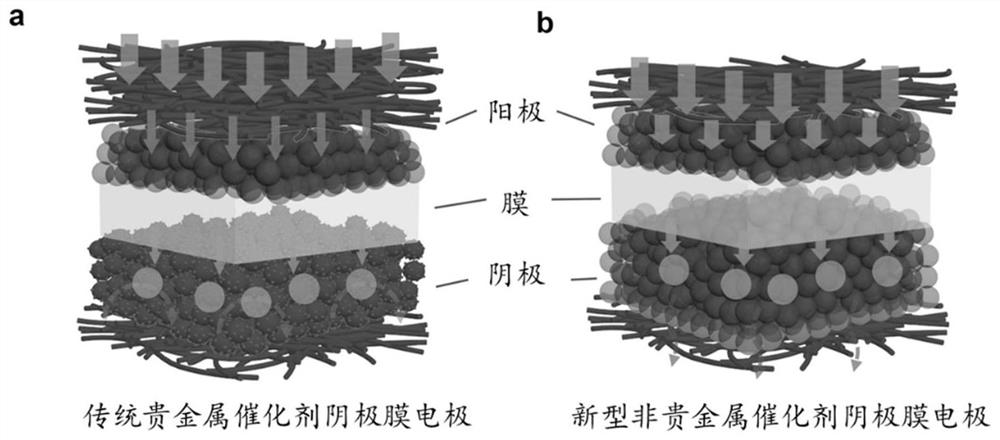

A methanol fuel cell and fuel cell technology, applied in fuel cells, circuits, electrical components, etc., can solve the problems of fuel permeation characteristics changing the cathode material transport process, difficult to meet the application requirements of performance and life, to eliminate catalyst poisoning, The effect of improving the fuel utilization rate and reducing the internal resistance of the battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

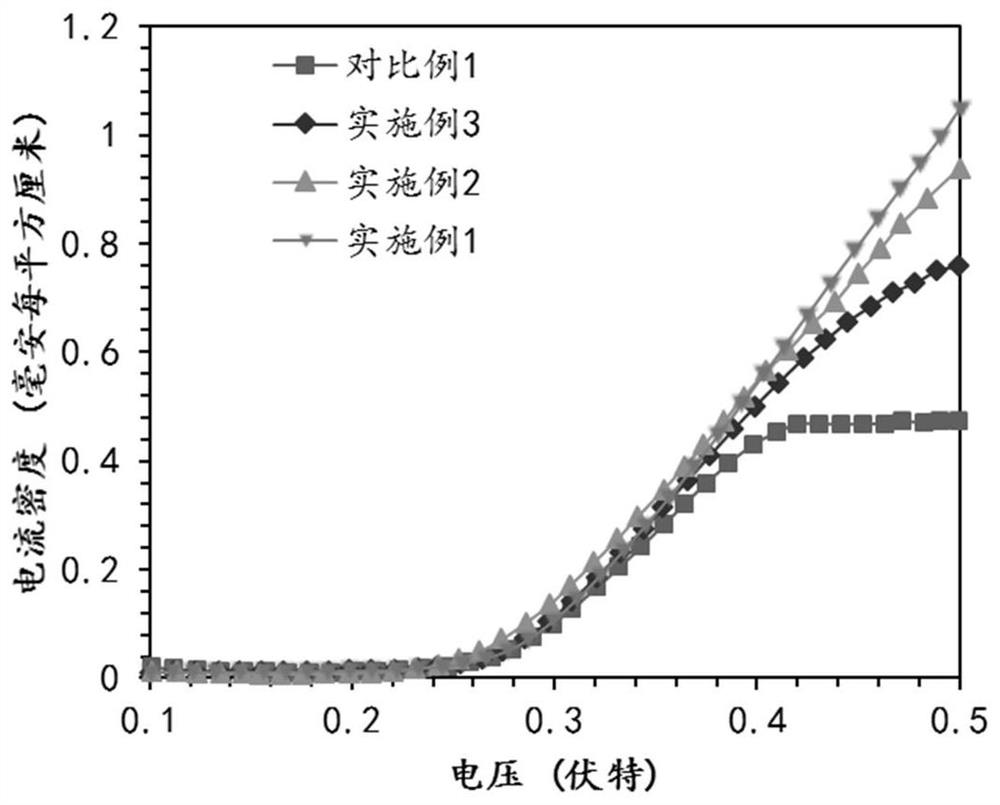

Embodiment 1

[0039] a. Preparation of gas diffusion electrode

[0040] A certain mass of carbon nanotubes and a certain mass of polytetrafluoroethylene are mixed evenly according to the mass ratio of 4:1, and a certain mass of water is added to disperse evenly, and the solid content of the slurry is 10%.

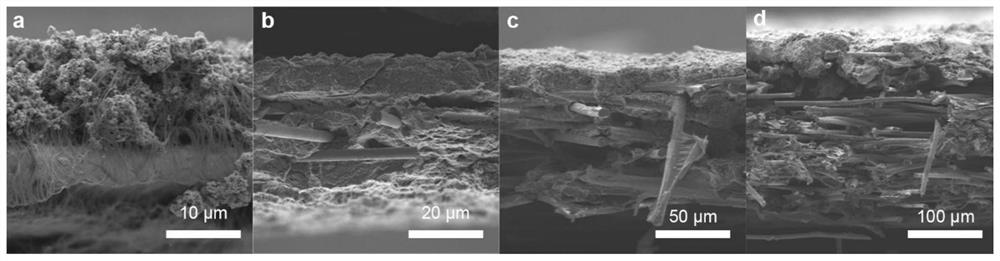

[0041]After the above-mentioned slurry is uniformly dispersed by ultrasonic, the next step of dispersion is carried out by using shear force stirring equipment, the linear speed of the stirring rotor is 30m / s, the temperature is 50°C, and the stirring time is 10min. After uniform dispersion, the ultra-thin gas diffusion layer is prepared by filtration. Spread the filter membrane with a pore size of 20nm to the bottom of the funnel, and vacuum filter the prepared slurry, so that the solid surface density is 100 μg / cm according to the area of the filter membrane 2 , After fully drying, it is peeled off for use. The average thickness is about 12 μm, and the measured porosity is about 78%...

Embodiment 2

[0067] a. Preparation of gas diffusion electrode

[0068] Mix a certain quality of carbon fiber and carbon nanotubes (mass ratio is 1:1), and a certain quality of polytetrafluoroethylene according to the mass ratio of 4:1, and add a certain quality of water to disperse evenly, and the solid content of the slurry is 10 %.

[0069] After the above-mentioned slurry is uniformly dispersed by ultrasonic, the next step of dispersion is carried out by using shear force stirring equipment, the linear speed of the stirring rotor is 30m / s, the temperature is 50°C, and the stirring time is 10min. After uniform dispersion, the ultra-thin gas diffusion layer is prepared by filtration. Spread the filter membrane with a pore size of 20nm to the bottom of the funnel, and vacuum filter the prepared slurry, so that the solid surface density is 400 μg / cm according to the area of the filter membrane 2 , After fully drying, it is peeled off for use. The average thickness is about 46 μm, and th...

Embodiment 3

[0075] a. Preparation of gas diffusion electrode

[0076] Mix a certain quality of carbon fiber and carbon nanotubes (mass ratio is 3:1), and a certain quality of polytetrafluoroethylene according to the mass ratio of 4:1, and add a certain quality of water to disperse evenly, and the solid content of the slurry is 10 %.

[0077] After the above-mentioned slurry is uniformly dispersed by ultrasonic, the next step of dispersion is carried out by using shear force stirring equipment, the linear speed of the stirring rotor is 30m / s, the temperature is 50°C, and the stirring time is 10min. After uniform dispersion, the ultra-thin gas diffusion layer is prepared by filtration. Spread the filter membrane with a pore size of 20nm to the bottom of the funnel, and vacuum filter the prepared slurry, so that the solid surface density is 1000 μg / cm according to the area of the filter membrane 2 , After being fully dried, it is peeled off for use. The average thickness is about 79 μm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com