Method for improving slow release effect of manure organic fertilizer

A technology for manure organic fertilizer and drying treatment, which is applied in the preparation of organic fertilizer, organic fertilizer, and biological organic part treatment, etc. Excellent gel coating effect, improving utilization rate, and improving the effect of coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

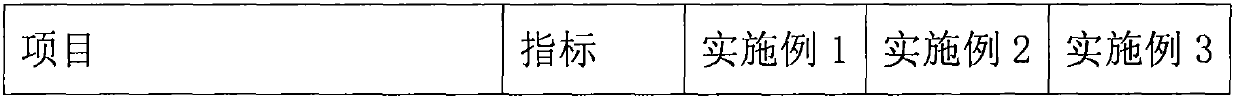

Embodiment 1

[0019] A method for improving the slow-release effect of manure organic fertilizer, comprising the following steps:

[0020] (1) After mixing wakame and bamboo shoot shells according to the ratio of 10:1, dry them, then crush them through a 40-mesh sieve, then add clear water to it according to the ratio of liquid to material volume ratio of 30, and then according to the enzyme concentration of 300U Add cellulase to it per ml, and after 3 hours of enzymatic hydrolysis reaction, a wakame enzymatic hydrolysis solution is obtained, wherein the temperature of the enzymatic hydrolysis reaction is 55° C., and the pH value is 5.0;

[0021] (2) After the solid-liquid separation of poultry and livestock feces, the solid feces are collected. In parts by weight, 80 parts of solid feces, 20 parts of straw powder, and 10 parts of sawdust are sequentially added to the fermentation tank, and then the compound microbial bacteria are added thereto agent, mixed and stirred evenly, a fermentatio...

Embodiment 2

[0024] A method for improving the slow-release effect of manure organic fertilizer, comprising the following steps:

[0025] (1) After mixing wakame and bamboo shoot shells according to the ratio of 15:1, dry them, then crush them through a 40-mesh sieve, then add clear water to it according to the ratio of liquid to material volume ratio of 35, and then according to the enzyme concentration of 350U Add cellulase to it per ml, and after enzymatic hydrolysis reaction for 3.5 hours, obtain wakame enzymatic hydrolysis liquid, wherein the temperature of enzymatic hydrolysis reaction is 58 ℃, and the pH value is 5.0;

[0026] (2) After the solid-liquid separation of poultry and livestock feces, the solid feces are collected. In parts by weight, 85 parts of solid feces, 25 parts of straw powder, and 13 parts of sawdust are sequentially added to the fermentation tank, and then the compound microbial bacteria are added thereto. agent, mixed and stirred evenly, a fermentation treatment...

Embodiment 3

[0029] A method for improving the slow-release effect of manure organic fertilizer, comprising the following steps:

[0030] (1) After mixing wakame and bamboo shoot shells according to the ratio of 20:1, dry them, then crush them through a 40-mesh sieve, then add water according to the ratio of liquid to material volume of 40, and then according to the enzyme concentration of 400U Add cellulase to it per ml, and after enzymatic hydrolysis reaction for 4 hours, a wakame enzymatic hydrolysis solution is obtained, wherein the temperature of the enzymatic hydrolysis reaction is 60° C., and the pH value is 5.0;

[0031] (2) After the solid-liquid separation of poultry manure, the solid manure is collected, and in parts by weight, 90 parts of solid manure, 30 parts of straw powder, and 15 parts of sawdust are sequentially added to the fermentation tank, and then the compound microbial bacteria are added thereto agent, mixed and stirred evenly, a fermentation treatment for 25 days, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com