Rubber composition, and preparation method and application thereof

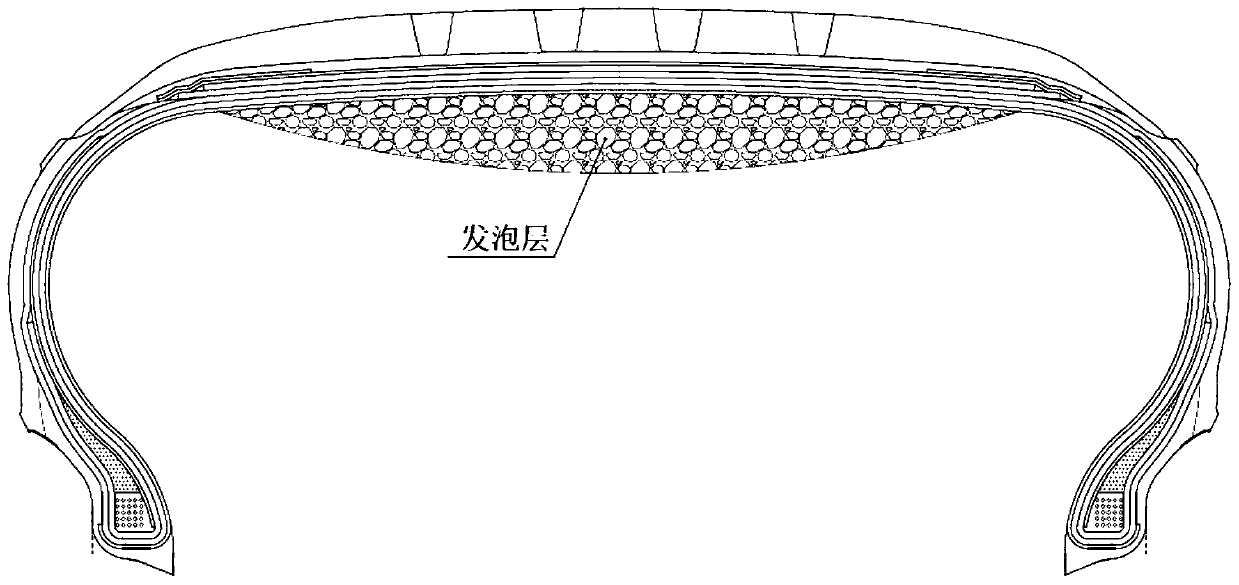

A rubber composition and natural rubber technology, applied in tire parts, transportation and packaging, special tires, etc., can solve problems such as easy to fall off, cumbersome fixing methods, etc., achieve good foaming effect, good sound absorption effect, and reduce decomposition temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] This embodiment is the preparation of tire

[0072] By weight: NR: 54kg, BIIR glue 126kg, carbon black 117kg, foaming agent azodicarbonamide 15kg, zinc oxide 5.4kg, stearic acid 3.6kg, oil 12.6kg, resin 4.5kg, thiazole accelerator 2.7kg, sulfur 0.9kg. The above-mentioned composition material is processed by a 2-stage mixing process, and the mixing is carried out in an F370 internal mixer, and the rotor speed is 10-60r / min; after the 2-stage mixing, the tablet is discharged from the mill; Add NR: 54kg, BIIR glue 126kg, carbon black 117kg, stearic acid 3.6kg, oil 12.6kg, resin 4.5kg, debinding temperature 130°C; add zinc oxide 5.4kg, thiazole accelerator 2.7kg, sulfur 0.9kg, the debinding temperature is 105°C. After parking for 4 hours, the thickness of the film is controlled at 3mm, and the width can be adjusted according to the size of the tire. After the calendered film is parked for another 4 hours, the tire blank is formed. When the tire is formed, a layer of film...

Embodiment 2

[0075] This embodiment is the preparation of tire

[0076] By weight: NR: 36kg, BIIR glue 144kg, carbon black 117kg, foaming agent azodicarbonamide 20kg, zinc oxide 5.4kg, stearic acid 5kg, oil 12.6kg, resin 4.5kg, thiazole accelerator 2.7 kg, sulfur 0.9kg. The above-mentioned composition material is processed by a 2-stage mixing process, and the mixing is carried out in an F370 internal mixer, and the rotor speed is 10-60r / min; after the 2-stage mixing, the tablet is discharged from the mill; Add NR: 36kg, BIIR glue 144kg, carbon black 117kg, zinc oxide 5.4kg, stearic acid 5kg, oil 12.6kg, resin 4.5kg, debinding temperature 130°C; add zinc oxide 5.4kg in the second stage, thiazole accelerator 2.7kg, sulfur 0.9kg, debinding temperature is 105°C. After parking for 4 hours, the thickness of the film is controlled at 3mm, and the width can be adjusted according to the size of the tire. After the calendered film is parked for another 4 hours, the tire blank is formed. When the ...

Embodiment 3

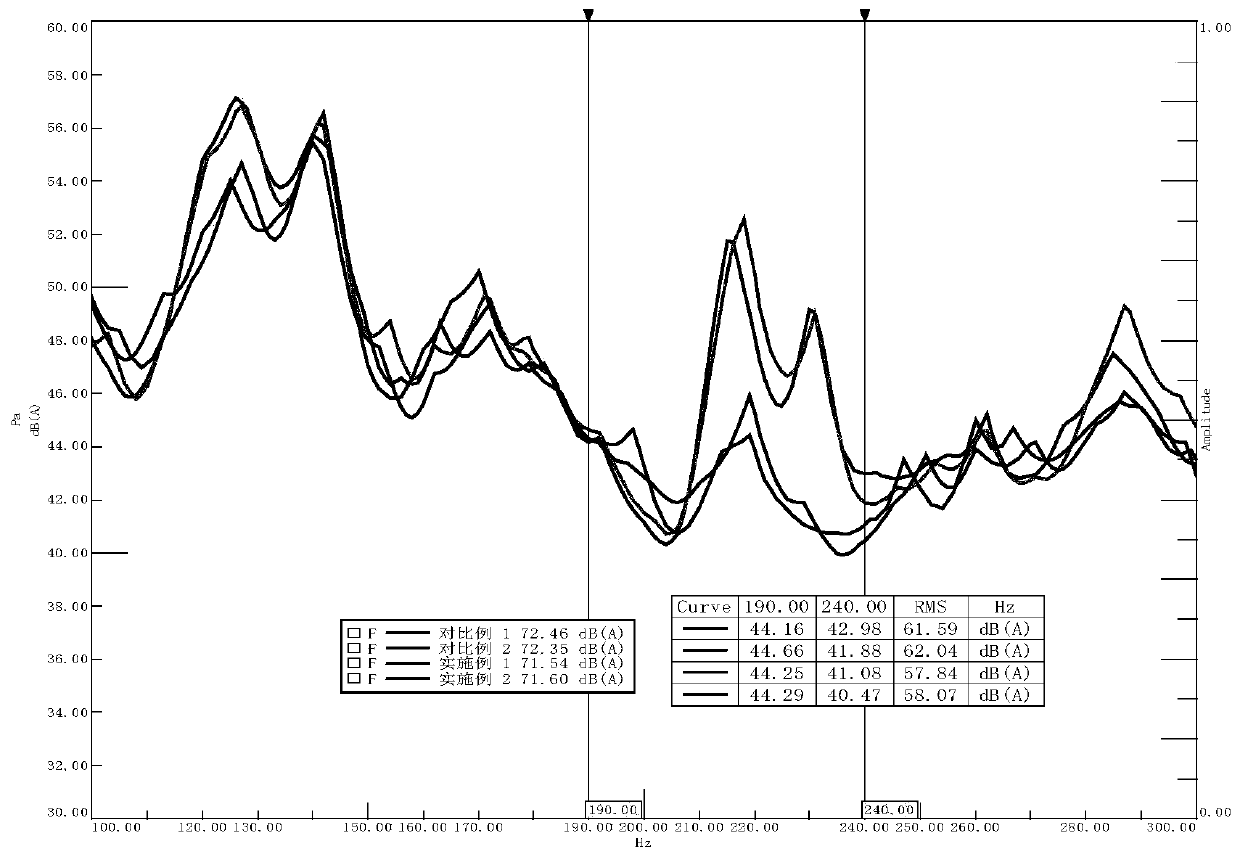

[0089] The tires prepared in Example 1, Example 2, Comparative Example 1 and Comparative Example 2 were tested for cavity noise in real vehicles.

[0090] The result is as figure 1 As shown, the corresponding peak value in the frequency range of 200-250 Hz is the cavity noise of the tire. For the tires prepared in Examples 1-2 of the present invention, the peak value generated in the frequency range of 200-250 Hz in the actual vehicle test is obviously lower than that of Comparative Examples 1-2, and the cavity noise is better, which shows that whether the rubber composition of the invention is Canceling the blowing agent or reducing the dosage of active agent can not reach the cavity noise level of the embodiment of the present invention. In addition, by comparing Example 1 and Example 2, it can be found that when the mass ratio of (3-30): (3-8) is adjusted in the amount of foaming agent and raw rubber, the peak value change in the range of 200-250Hz Not much.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com