Novel carbon fiber reinforcement matching primer and preparation method thereof

A carbon fiber reinforcement, a new type of technology, applied in the field of building structural adhesives, can solve the problems of poor bonding effect of wet interface, failure to proceed normally, poor bonding effect of wet interface, etc., achieve good economic significance, improve service life and Improvement of safety performance and operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

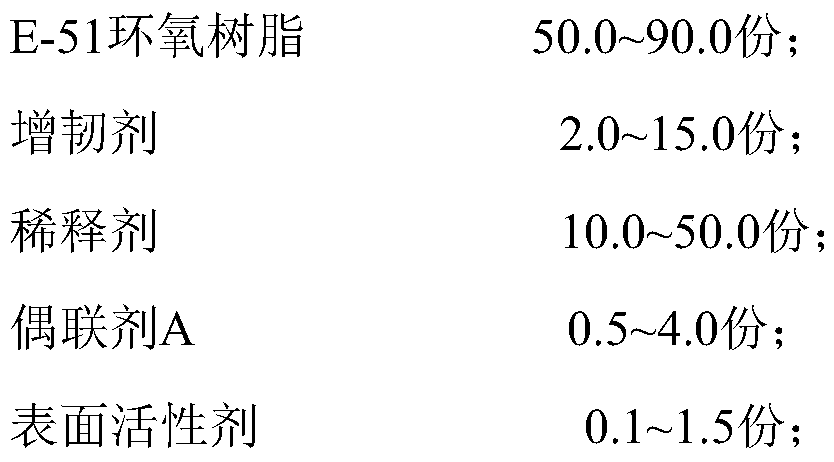

[0039] A new type of primer for carbon fiber reinforcement, including component A and component B, the mixing ratio of component A and component B by weight is 2:1.

[0040] Among them, the first component includes the following components in parts by weight: 71.0 parts of E-51 epoxy resin, 8.0 parts of toughening agent (3 parts of polysulfide rubber, 5 parts of QS-BE), 18.0 parts of diluent (benzyl shrink 8 parts of glyceryl ether, 10 parts of butyl glycidyl ether), 2.0 parts of coupling agent A (KH560), 1.0 parts of ethoxylated nonionic fluorocarbon surfactant (FS0-100).

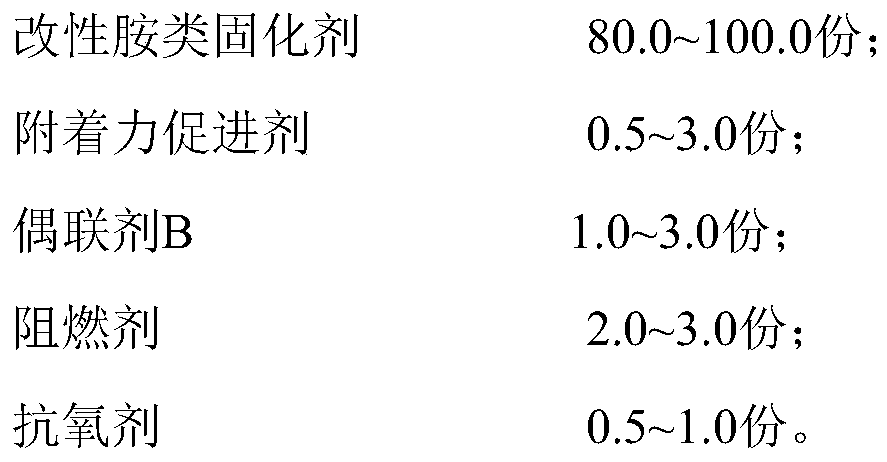

[0041] Component B includes the following components in parts by weight: 93.0 parts of modified amine curing agent (45 parts of T-31, 48 parts of 1805C), 3.0 parts of 2,4,6-tris(dimethylaminomethyl)phenol (DMP -30), 2.0 parts of coupling agent B (KH550), 2.0 parts of flame retardant DOTCP and 0.5 parts of antioxidant 1076.

[0042] The preparation method of above-mentioned primer comprises the following s...

Embodiment 2

[0048] A new type of primer for carbon fiber reinforcement, including component A and component B, the mixing ratio of component A and component B by weight is 2:1.

[0049] Wherein, the first component includes the following components in parts by weight: 68.0 parts of E-51 epoxy resin, 5.0 parts of toughening agent (QS-BE), 25.0 parts of diluent (12 parts of butyl glycidyl ether, butanediol 13 parts of diglycidyl ether), 1.5 parts of coupling agent A (KH560), 0.5 parts of ethoxylated nonionic fluorocarbon surfactant (FS0-100).

[0050]Component B includes the following components in parts by weight: 95.0 parts of modified amine curing agent (33 parts of T-31, 62 parts of 1805C), 2.0 parts of 2,4,6-tris(dimethylaminomethyl)phenol (DMP -30), 1.0 parts of coupling agent B (KH550), 2.5 parts of flame retardant DOTCP and 0.8 parts of antioxidant 1076.

[0051] The preparation method of above-mentioned primer comprises the following steps:

[0052] (1) Add each component in the ...

Embodiment 3

[0058] A new type of primer for carbon fiber reinforcement, including component A and component B, the mixing ratio of component A and component B by weight is 2:1.2.

[0059] Wherein, component A includes the following components in parts by weight: 71.0 parts of E-51 epoxy resin, 8.0 parts of toughening agent (polysulfide rubber), 18.0 parts of diluent (butyl glycidyl ether), 2.0 parts of coupling Agent A (KH560), 1.0 parts of ethoxylated nonionic fluorocarbon surfactant (FS0-100).

[0060] Component B includes the following components in parts by weight: 91.0 parts of modified amine curing agent (50 parts of T-31, 41 parts of 1805C), 3.0 parts of 2,4,6-tris(dimethylaminomethyl)phenol (DMP -30), 2.0 parts of coupling agent B (KH550), 3.0 parts of flame retardant DOTCP and 1.0 parts of antioxidant 1076.

[0061] The preparation method of above-mentioned primer comprises the following steps:

[0062] (1) Add each component in the formula of component A to a blender, fully mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com